L.E.S.S. SA shapes automotive lightings

Sector: Precision mechanics and opticsSpecialist field: OpticsAutomotive lighting design requires interdisciplinary understanding to create high-performing products. The Advanced Product and Technology Development team at L.E.S.S SA performs Multiphysics simulations including flow, thermal, mechanical, and optical calculations, to design products that meet physical expected performances and ECE regulation R87 requirements.

Summary

Task

Automotive lighting design requires interdisciplinary understanding to create high-performing products in a design environment with a low thermal budget and limited space.

Solution

Due to the nature of the problem, a Multiphysics approach is needed to analyze the thermal and mechanical effects on optical performance.

Customer benefits

L.E.S.S. SA can anticipate the delivery of innovative automotive lighting through the use of Ansys multiphysics software and the support CADFEM.

Project Details

Task

Automotive lighting design requires interdisciplinary understanding to create high-performing products in a design environment with a low thermal budget and limited space. Tight tolerances of optics and the demanding requirement of the automotive industry together create a challenge for engineers in this field.

The Advanced Product and Technology Development team at L.E.S.S SA constantly work on developing reliable products that enable flexible designs under the harsh conditions of the automotive industry ensuring high-performance and compatibility with international automotive standards. ANSYS products are utilized in the R&D process to ensure product safety by performing Multiphysics simulations including flow, thermal, mechanical, and optical calculations.

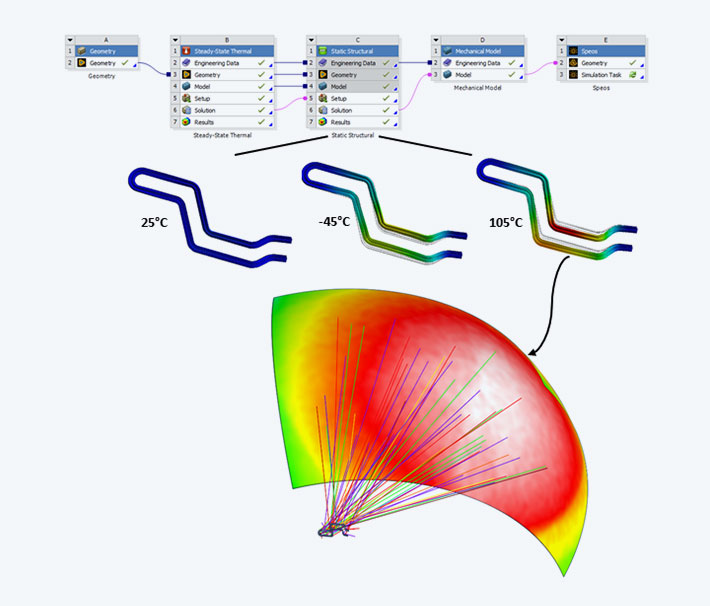

The working conditions in a vehicle can change drastically due to outside temperatures and heat dissipated from the vehicle. Therefore, the products must endure environments with temperatures from sub-zero levels (typ. -45°C) to elevated temperatures (typ. 105°C) while satisfying the optical specifications of international automotive standards. The thermal dilatation due to temperature change must be considered to ensure that the optical performance is not affected over the full range of environmental conditions.

Customer Benefit

Appropriate simulations give L.E.S.S a strong advantage in terms of product performances and responsiveness to a demanding market before testing. These lightings are compliant with the ECE regulations and take account of thermal deformations and their effects on the optical performance. These benefits were accomplished by:

- Using optimization tools in different stages of design to provide the best possible products in the shortest time.

- Consideration of various working conditions with simulations to make sure the products will serve as expected through the product life cycle.

- Decreasing the number of physical prototypes/tests to reduce design iterations with customers to save time

- Analyzing the capabilities of products in a large range of working conditions and power requirements to better communicate to customers the product capabilities and ensure that customer-specific requirements (CSR) are fulfilled.

Solution

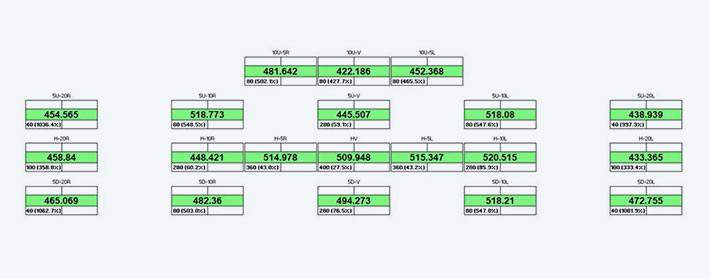

Due to the nature of the problem, a Multiphysics approach is needed to analyze the thermal and mechanical effects on optical performance. Ansys Workbench was used to first perform a thermal analysis to determine the temperature gradient on a daytime running lamp module (DRL). The thermal field is then posed as loading in a mechanical simulation to estimate the thermal deformation of the part at temperatures ranging between -45°C to 105°C. Finally, the resulting deformed body is transferred to an optical simulation in Ansys SPEOS to check the illumination performance against the requirements of ECE regulation R87 concerning the daytime running lamps. This analysis setup provides a complete tool that helps evaluate the products, select materials, and ensure compliance with international standards from the beginning of the design iterations.

Images: © L.E.S.S. SA