Memories of Dr. Alfred Zimmer, who would have been 100 in 2020

FEM pioneer and trailblazer in the automobile industry

At the end of the fifties, the development of the finite element method (FEM) started behind closed doors at Daimler-Benz. This inaugurated an exciting era which is well worth illuminating even more than 60 years later, for Dr. Alfred Zimmer’s ideas revolutionized Daimler-Benz’s design process.

When it came to computers, companies were at a loss

Dr. Alfred Zimmer was a pioneer and trailblazer when it came to applying the finite element method to automotive development. He thus became a prime mover for many other sectors, such as civil engineering, bridge construction, crane design, shipbuilding, metal construction, and medicine, to name but a few. Even in the early sixties, it was only the aerospace industry that was employing FEM analysis.

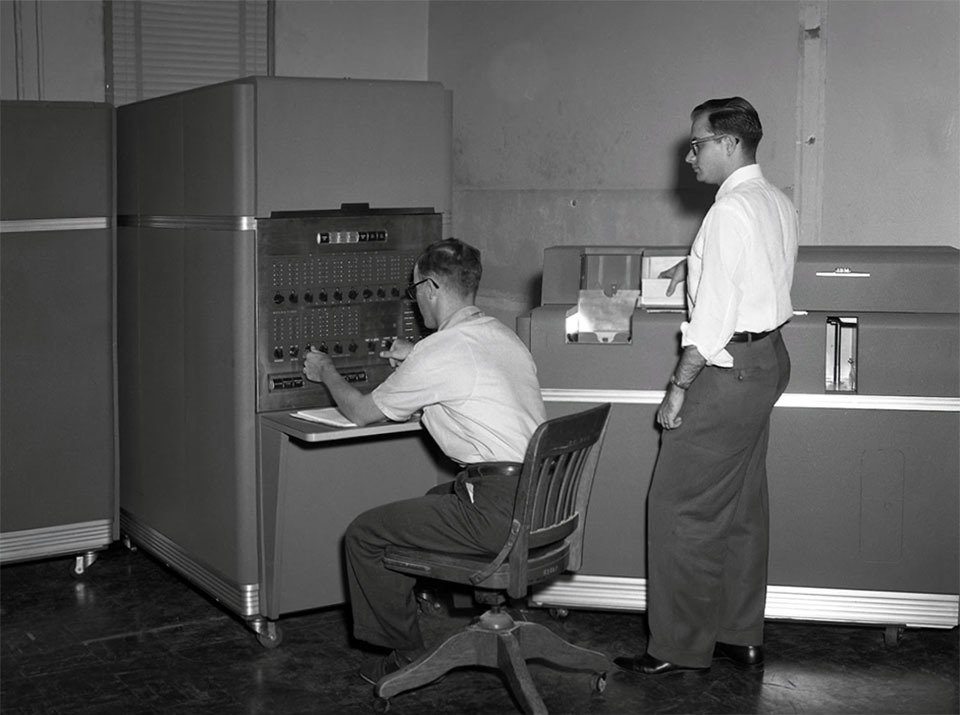

In those days, people were still working on Saturday mornings. So, IBM chose Saturday afternoons as the time when they would offer initial training courses to folks interested in computers. These courses, which were paid for by the trade union, took place in Sindelfingen (in the "small tower block"). The first mainframes, IBM 650s, were at the disposal of these willing pupils.

Big companies had only a scant interest in their employees attending this type of training course. When it came to computers, they were initially at a loss. At the Daimler-Benz factory, Dr. Zimmer was told in no uncertain terms: “We make automobiles here – not computers.” Not only that: people thought that “four mainframes” would be sufficient to cover the needs of German industry for a long time to come. How wrong they were!

At the time, the use of electronic computers was reserved for the big university-based research institutes, whose level of accomplishment by 1965 can best be illustrated by looking at The Aerospace Institute (the home of Prof. Argyris) – Stuttgart University was then known. It was at this time that, while working in Daimler-Benz’s preliminary development department, the computational engineer, Dr. Alfred Zimmer, whose background was in civil engineering, started writing a calculation program for space frames, which he called “frame calculation” (FC). At Daimler-Benz, the first scientific computer to be used in engineering, the IBM 650, had just been replaced by its successor, the IBM 1620.

Fabulously-specced memory – with a capacity of 6 kilobytes

This new tool – an all-transistor, assembler-programmable system with a fabulous 6-KB memory – worked with a punch-card paper-tape-reader and a tabulator. The FC program endured a double baptism of fire. The first was in connection with calculation of the frame floor of the W 100 (the legendary Mercedes-Benz 600, built between 1964 and 1981). On its debut, following a ten-hour calculation period, the results were so accurate that the test department that had carried out the measurements assumed they were the result of data theft. The second important field test had to do with the journey of the British queen, Queen Elizabeth II, together with her husband, Prince Philip, during a state visit to Munich in 1965, during which she used the new W 100 official state car, the 600 Pullman Landaulet, which had been analyzed using the new FC program.

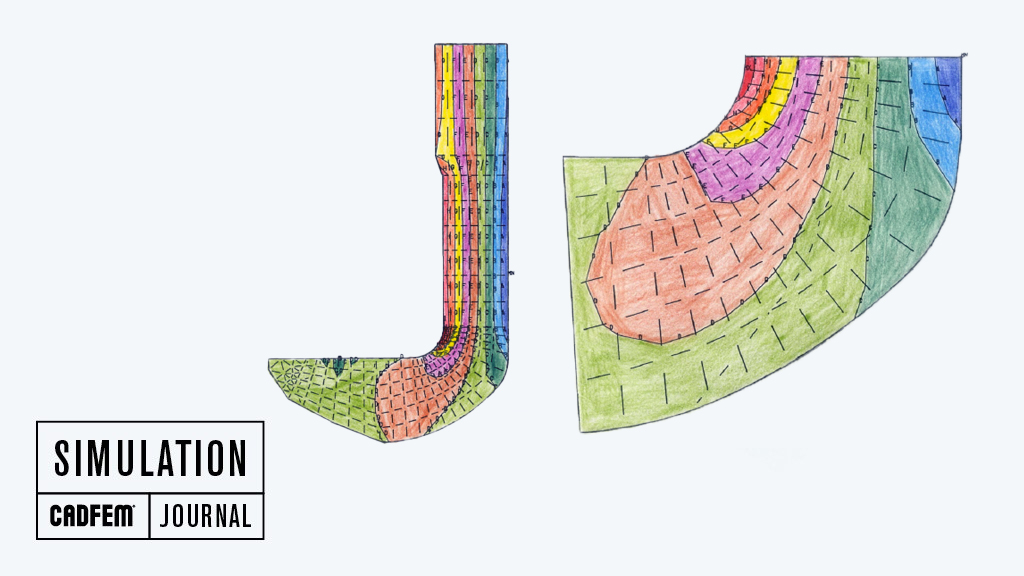

Starting in 1963, the first vehicle body calculations were carried out using a mix of bar elements and surface elements. The first of these was the Auto Union F 102, at a time when Auto Union still belonged to Daimler-Benz. In order to obtain additional comparative values, a subsequent calculation was performed for the “Mercedes-Benz 230 SL” W 113 sports car. This, above all, involved the trial and subsequent rapid, successful adoption of the shape optimization method for rigidity design – the purpose of which is to reduce weight – that is still in use today, based on the body deformation analysis method. This same method was also applied to the first bus.

A vehicle body model with 319 nodes and 443 elements

Dr. Zimmer, together with six other programmers, developed the ESEM (elastostatic element method) FORTRAN program for the IBM 360. The first important application of ESM came in 1967, during development of the W115 (the MB 200-240 D). The model used for this vehicle – calculated using half a vehicle, due to the reduction in calculation time – had 319 nodes, 443 elements, and 1,684 degrees of freedom. The entire roof consisted of six quadrilateral elements and four triangular elements. The software was only deployed about a year prior to the start of serial production, when difficulties were being experienced in the test department in connection with the vehicle.

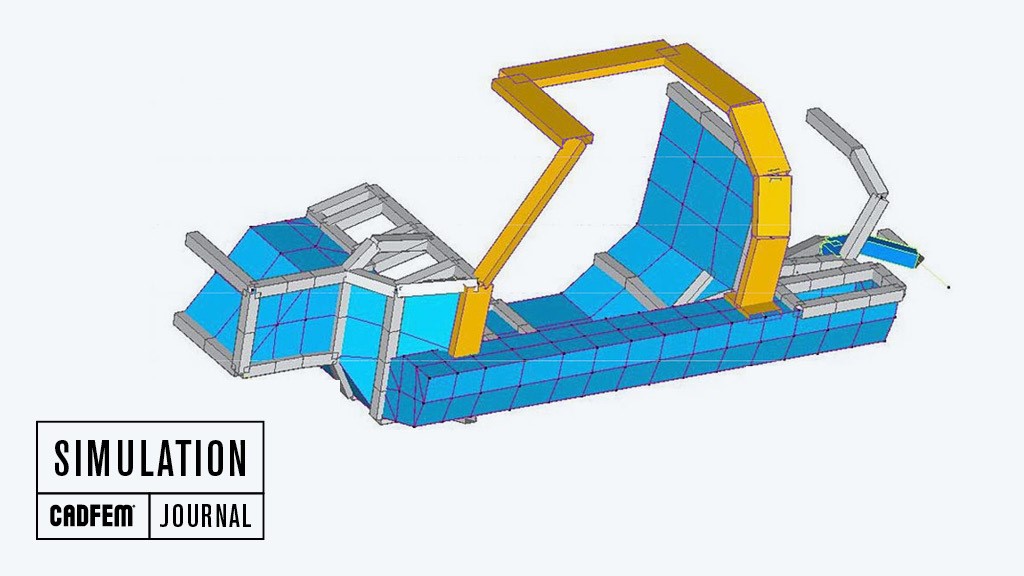

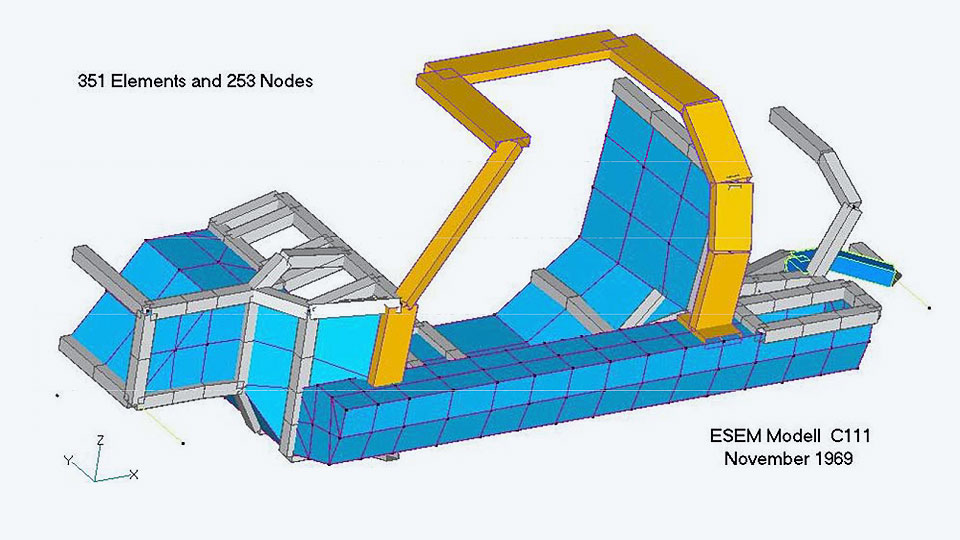

In the fall of 1969, the calculation department led by Dr. Alfred Zimmer was given the task of analyzing the body of the Wankel-engined C 111 during the course of its development. As no drawings were initially available, all they were getting from the board of management was specifications: “…with gull-wing doors, roll bars, propulsion via a three or four-rotor Wankel engine mid-mounted behind the driver, with tanks in the outer sill.” From this starting point, the team defined the axle and the wheelbase and also the height of the vehicle. After that, the calculations relating to the design and construction of the vehicle were initiated, giving due weight to the technical constraints. Completing the prototype C 111 only took another six months.

Dr. Zimmer’s groundbreaking approach makes it onto German TV

This groundbreaking approach was complimented by a lavishly produced film commissioned by IBM’s marketing department. Dr. Zimmer was invited to the studios of the German TV station ZDF, in Mainz, so that he could tell other people about his methodology. IBM was intending to use this film, “The Car that Came Out of the Computer” – which was dubbed into both English and Spanish – to boost the sales of its computers.

IBM showed the film to American car-company managers, with the result that the finite element method became a standard tool for automotive manufacturers. During this period, Dr. Zimmer was engaging in a mounting number of lecture tours in England, Scandinavia, and the USA. In the early seventies, head of the calculation department of the automobile predevelopment, Dr. Zimmer had about 30 colleagues who, in addition to ESEM, were using FEM-based standard software such as ASKA, NASTRAN, and also TPS10 – a successor system which had been developed by the ESEM development team. Dr. Zimmer’s ideas set in motion the systematic application of the finite element method in the sphere of automotive development throughout the world.

“Passive safety” – crash protection and occupant protection – plays an important role at Daimler-Benz. FEM simulation has meant that the number of real-world crash tests has been reduced to a minimum, which has saved automobile companies considerable time and a great deal of money!

This is an abridged version of an article by Klaus Zimmer, Alfred Zimmer’s son

The full version of this article, and also additional information, can be found on his homepage: www.fem-dtm.com

Of particular interest is the film that is accessible via Klaus Zimmer’s site, which was not only shown in Cannes, but was awarded first prize in the “Industrial Films” category.

At the 2008 CADFEM users meeting, Peter Groth, a colleague of Alfred Zimmer gave a lecture on how the C 111 sports car was developed using the ESEM simulation program.

© Images: private | Translation: Kieran Scarffe