Duty cycle crawler cranes, hydraulic crawler cranes, deep foundation engineering equipment

Liebherr-Werk Nenzing builds on Ansys and CADFEM

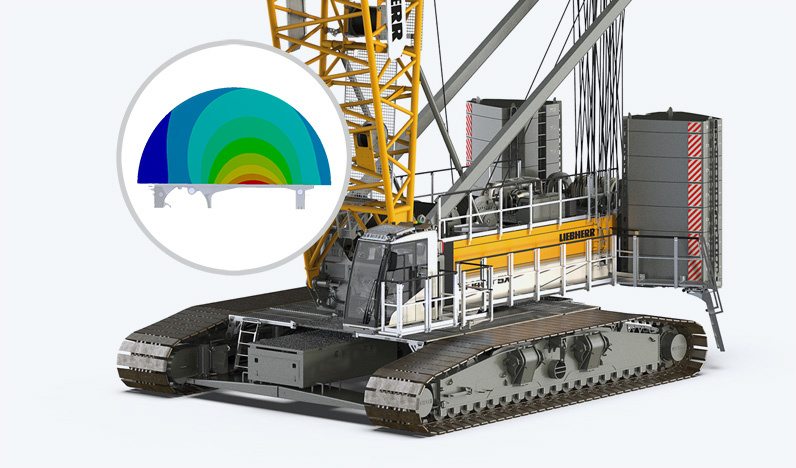

Liebherr-Werk Nenzing GmbH continues to set standards in crawler cranes, hydraulic crawler cranes and various types of deep foundation engineering equipment. Simulations with Ansys are firmly anchored in product development and will be further intensified. Because there is so much more to accomplish, digitalization, electrification, and the topic of sustainability have made their way into the field of deep foundation engineering.

Liebherr-Werk Nenzing: Innovation in Construction Machines

In Vorarlberg, in the very west of Austria, lies the town of Nenzing. Since 1976, this has been the home of the global innovation leader for construction machines. Being an innovation leader is not a snapshot in time, but rather a continuous challenge. Liebherr-Werk Nenzing GmbH accepts this challenge and continues to attract attention, with new products, awards and world records.

Engineers at Liebherr-Werk Nenzing have long been concerned with the construction site of the future. It demands digital, quiet and environmentally compatible products, which Liebherr has already demonstrated today with the world’s first battery-powered construction machines in their “unplugged” series. In addition, new IT solutions and assistance systems are needed to make the processes at the overall construction site system more efficient. With software for the virtual planning of crane operations or innovative training simulators for greater safety, Liebherr is setting the pace in these areas as well.

Data transmission, management and analysis shape the networked construction site. More than 230 technicians in Nenzing – including around 100 IT specialists – are currently researching the next generation of digital solutions for you.

Pioneers of simulation in small and medium-sized businesses

In the 1980s, simulations based on virtual prototypes of future products were by no means a matter of course; especially not for medium-sized companies. In Nenzing, they were already part of the repertoire of Liebherr engineers, which was an enormous development advantage. “The immense potential of simulation technology, namely being able to accurately model, evaluate and improve load conditions all by computer, was recognized here very early on,” says Bertram Peer, Structural Engineering Department Manager, with pride. He adds, “from the very beginning, Ansys software was primarily used, and the then ‘start-up’ CADFEM was also already on board as a partner for consulting, training, and hotline support.”

Simulation – from idea to the test bench

Bertram Peer is part of today’s Nenzing team which includes more than 40 engineers who use Ansys products in almost all areas of product development for the analysis of the most varied physical problems. Ansys simulations accompany the entire development process:

- From the identification of initial product ideas …

- … to their precise development into a detailed digital prototype …

- … to the verification of the finished product …

- … which is carried out in close cooperation with test engineers at the test bench.

Systematically to the needle in the haystack

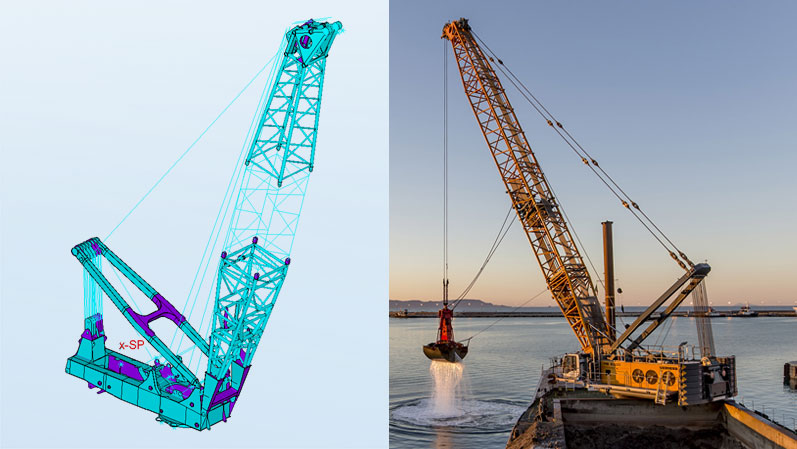

The starting point of every development is the derivation of the basic component design. Instead of rough analytical calculations, Liebherr relies on simulation tools that are supplied with measurement data and empirical values. After all, we are talking about complex machines where countless configurations, boundary conditions and load cases have to be taken into account. “In the case of the LR 1400 SX, our latest crawler crane with a maximum load capacity of 400t, there were several thousand potential model configurations at the start, each with 35 load cases,” explains Bertram Peer, Structural Engineering Department Manager. He continues, “I can’t imagine a target-oriented analysis without simulation support.” And this is far from just being about details.

Once the essential component dimensions and load cases are available, the detailed consideration of the most promising options begins. First comes the geometry import from the CAD system Creo, the simulation-oriented preparation and meshing of the models with Ansys DesignModeler, Ansys SpaceClaim and Ansys Mechanical.

This is followed by the actual simulation in the standard program Ansys Mechanical or in Mechanical APDL, a variant enriched with empirical values and individualized by and for Liebherr. Tightly interwoven modules ensure high quality and low error-proneness in data handling as well as robust contact algorithms for the exact modeling of complex mechanisms and connections. A particular strength of Ansys is also used for non-linear phenomena, be it in the geometry of the slim boom construction or in material behavior. For example, when safeguarding against overloads.

Bertram Peer, Abteilungsleiter Statik, Liebherr-Werk NenzingI cannot imagine a target-oriented analysis without simulation support.

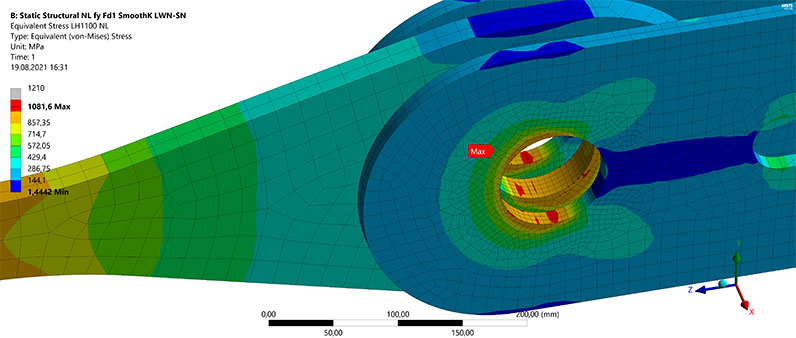

Detailed consideration of safety-relevant components

The safety of machinery is top priority. The high requirements that construction machines must meet for their approval and the quality demands of Liebherr's customers mean that conservative implementation of current standards and guidelines is often not enough.

Liebherr engineers therefore go one step further: In order to rule out any risk, the areas of the components subject to particularly high stresses are checked using extremely detailed models and taking into account all conceivable nonlinear effects.

More than structural mechanics

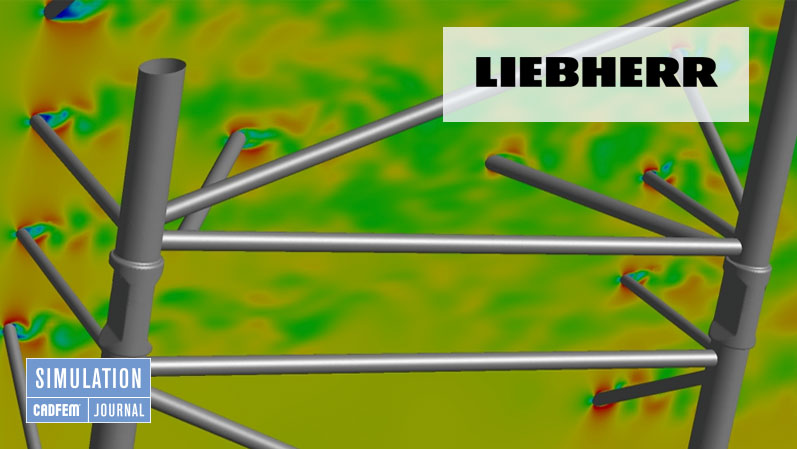

In addition to structural mechanics, further simulation disciplines are used during the development of the digital prototype. Computational fluid dynamics (CFD) simulations are used, among other things, to analyze and optimize the thermal balance of the machines. Background: Due to the compact design and the high amount of installed power, every detail is important when it comes to cold air flow. With CFD, developers gain precise insights into the systems and can design them in such a way that maximum efficiency of the machines is achieved with minimum fuel consumption.

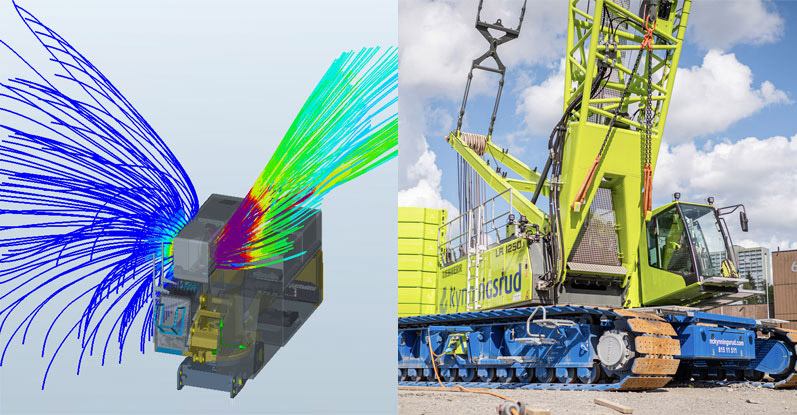

The electrification of construction machinery is a big topic. Liebherr-Werk Nenzing GmbH set a milestone in 2019 by launching the LB 16 unplugged, the world’s first battery-powered drilling rig. This was followed a short time later by the LR 1250.1, the first electric crawler crane.

In battery operation, cooling is an important consideration – and another case for CFD. Using flow simulations with Ansys Fluent, an ideal cooling unit placement was determined, taking into account all components inside the machine. Further fields of application for CFD are the analysis of the load on machines caused by wind, the optimization of the airflow of the cabin air conditioning and the design of the exhaust system for machines with combustion engines.

Quieter in and around the vehicle due to acoustic simulation

Acoustics is another issue that has gained considerable importance for construction machinery. The explanation is simple: construction site noise, especially within city areas, is no longer accepted by the public without complaint and is subject to increasingly rigid limits.

Liebherr’s claim is to minimize noise pollution from machines, both for the surrounding area as well as for the operators and construction workers who find themselves inside or in the immediate vicinity of these machines.

Today, Liebherr engineers use acoustic simulations of the machines to systematically assess various measures and their effectiveness for reducing acoustic emissions during the development of the digital prototypes.

Bertram Peer, Structural Engineering Department Manager, Liebherr-Werk NenzingAnsys products are an integral part of our development processes, and CADFEM has been supporting us as a reliable partner for decades.

“Early adopter” and visionary

“Ansys products are an integral part of our development processes, and CADFEM has been supporting us as a reliable partner for decades,” says Bertram Peer, summarizing the success story of simulation at Liebherr with Ansys and CADFEM. And it continues.

Those responsible at Liebherr are very closely following the direction in which simulation technology is developing. They are even involved - at least indirectly - in its dynamic expansion, in that wishes and ideas are often brought to the attention of Ansys and partner CADFEM for discussion. The enormous digital transformation process of the economy is an additional push for digital development tools such as Ansys and the possibilities of simulation. Classic application areas are being expanded, and more and more new areas, including niches, are being opened up by innovative simulation tools. The current and future possibilities of simulation are well known at Liebherr and are being continually evaluated.

Nenzing is ready for the digital future.

Liebherr-Werk Nenzing GmbH

Bertram Peer

www.liebherr.com

Author: Alexander Kunz, CADFEM

Images: © Liebherr

Published: June 2022

Contact CADFEM