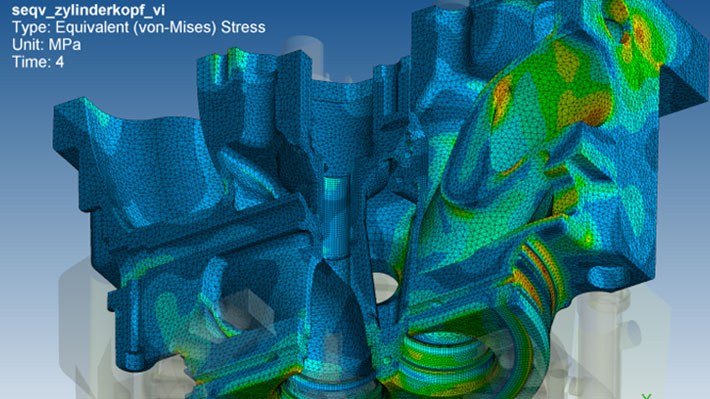

Ansys CFD and FEM analysis of a marine engine cylinder head

Sector: Machinery and plant engineeringSpecialist field: Structural mechanicsMAN Diesel SE develops and produces marine engines. In order to achieve the highest possible efficiency and durability of the engines, CADFEM has been commissioned to perform a simulation optimization.

Summary

Task

Modern engine development must combine economic aspects with high technological standards. Development at MAN Diesel SE aimed to reduce the weight of a marine engine with a new design. CADFEM used Ansys simulation tools to check whether the more efficient design of the cylinder head could withstand the loads and achieve a comparable life cycle despite the lower weight. This would significantly increase the economic efficiency.

Solution

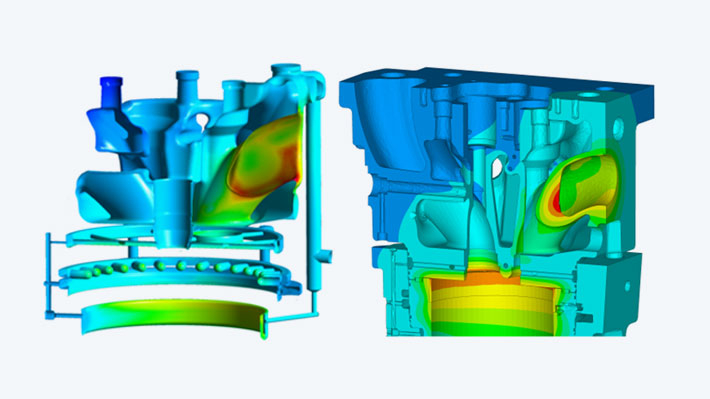

A CFD analysis with Ansys CFX covering the cooling and combustion process determines the thermal behavior within the engine and provides the basis for a subsequent stress analysis. This mechanical analysis implies multiple load cases describing the combustion cycle, as well as temperature-dependent material properties and nonlinear contacts in a comprehensive finite element model. This was followed by a life cycle analysis.

Customer benefits

The complex analysis of engine behavior provides information on contact pressure and possible gaps in the combustion cycle. This information is used to rule out undesirable effects on the thermomechanical behavior of the engine and its individual parts as early as the design phase.

Project Details

Task

Modern engine development must reconcile economic aspects with high technological standards. Development at MAN Diesel SE aimed to reduce the weight of a marine engine with a new design. CADFEM used Ansys simulation tools to check whether the more efficient design of the cylinder head could withstand the loads and achieve a comparable service life despite the lower weight. This would significantly increase the economic efficiency.

Customer Benefit

The complex analysis of the engine behavior provides information about the contact pressure and possible gap formations in the combustion cycle. This information is used to rule out undesirable effects on the thermomechanical behavior of the engine and its individual parts as early as the design phase.

Solution

A CFD analysis with Ansys CFX covering the cooling and combustion process determines the thermal behavior within the engine and provides the basis for a subsequent stress analysis. This mechanical analysis implies several load cases describing the combustion cycle, as well as temperature-dependent material properties and nonlinear contacts in a comprehensive finite element model. This was followed by a durability analysis.

Images: © MAN Diesel SE