Our independent CADFEM simulation experts have their fingers on the pulse of the times and are familiar with the challenges that companies face, the trends that software developers encounter and the innovation potential that simulation harbors.

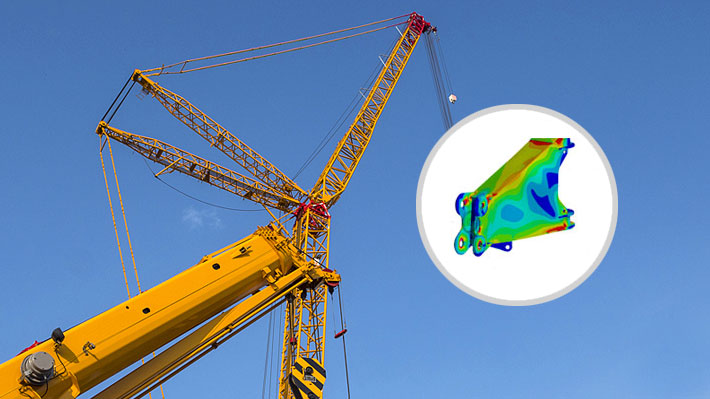

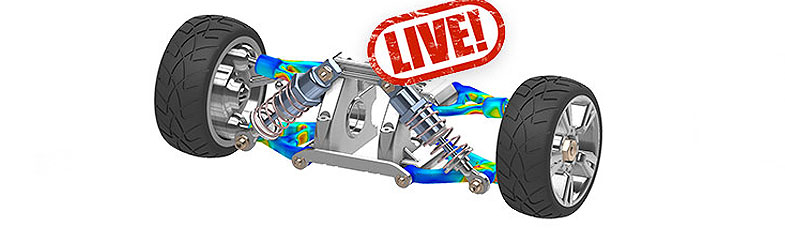

Simulation expertise in a multitude of topics and industries

As an independent simulation expert with many years of experience, CADFEM defines top topics in many industries, as numerous sample client scenarios prove. Benefit from our top contacts with market leaders in key on-trend industries.

Focusing on industries and markets

Every client has specific requirements. With our comprehensive industry know-how and wide-ranging client expertise, we therefore offer you suitable simulation software products as well as supplementary services and solutions for efficient use in your market. With these tools at your disposal, you can exploit the full potential of simulation for your specific business.

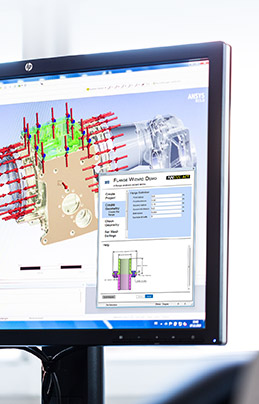

More than 2.300 CADFEM clients are testament to the excellent work we do and to our industrial diversity

With products, services and expertise from a single source, our clients can make the most of their simulations – and often develop groundbreaking product and process innovations. Read our reference clients’ and reference projects’ exemplary success stories.

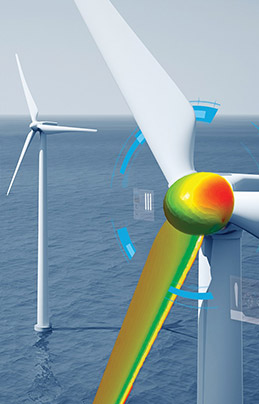

Current highlight topics

The current speed of change set by digitalization is challenging the traditional approaches taken by entire industries. Read here to find out what topics in the digital era are shining the spotlight on your company’s innovation and what role simulation is playing in this regard.