Verification of non-catalogued weld seam shapes according to DIN 15018

Sector: Machinery and plant engineeringSpecialist field: Structural mechanicsThe welded seam shapes of Maurer Rides' roller coasters are not always found in the usual notch drop catalogs. With CADFEM, however, verification was still possible.

Summary

Task

Structural-mechanical considerations sometimes lead to weld seam shapes that are not included in the usual notch case catalogs. These cannot be verified directly with the nominal stress concept, e.g. according to DIN 15018 (crane construction DIN). However, steel structures of roller coasters must be verified according to DIN 15018.

Solution

Determination of the load conditions for the respective weld seam in ANSYS Mechanical, calculation of the nominal stress in the R1MS model with subsequent comparison in DIN 15018.

Customer benefits

With the solution developed by CADFEM, the prescribed verification according to DIN 15018 is successful, although the weld seam forms are not available in the usual notch case catalogs.

Project Details

Task

If a structure contains a very large number of welds, their rational manufacturability has a significant influence on the shape. In addition, structural-mechanical considerations sometimes lead to weld seam shapes that are not included in the usual notch case catalogs. These cannot be verified directly with the nominal stress concept, e.g. according to DIN 15018 (Kranbau-DIN). However, steel structures of roller coasters must be verified according to DIN 15018. Therefore, it is necessary to develop a procedure for the classification of non-cataloged weld seam shapes in the notch case catalog of DIN 15018.

Customer Benefit

With the solution developed by CADFEM, the prescribed verification according to DIN 15018 is successful, although the weld seam forms are not available in the usual notch case catalogs.

Solution

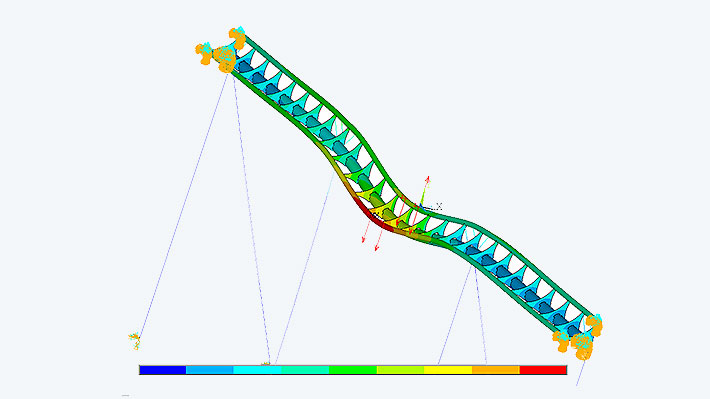

- Determination of the load ratio for the relevant weld seam in the FE model of the guideway when the joint is passed. This results in the notch-case-dependent limit stresses from DIN 15018

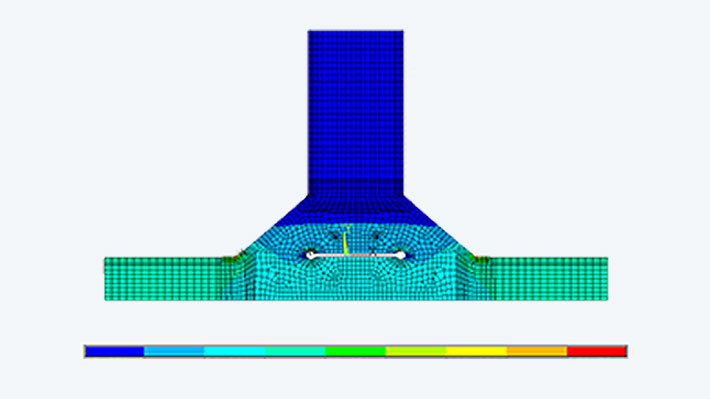

- Calculation of the nominal stress associated with FAT225 (notch stress in 1mm radius) in the R1MS model of an exemplary weld joint.

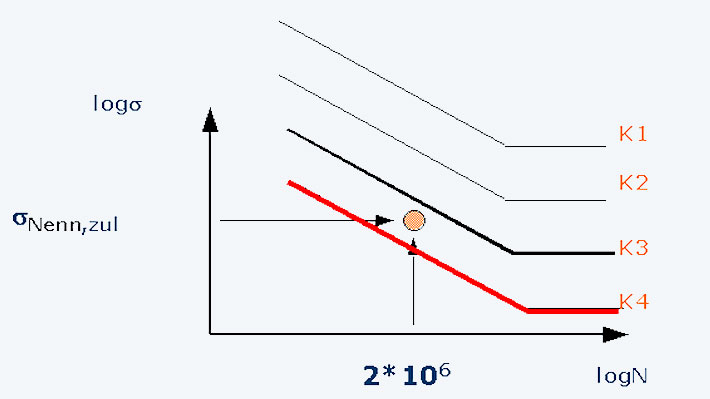

- Comparison of the nominal stress determined in the R1MS model with the DIN15018 nominal stresses of the corresponding notch classes

Images: © Maurer