Life cycle analysis with structural-mechanical FEM simulation

Sector: Consumer goods/durable goodsDESKO GmbH has been developing data security solutions and readout devices since 1991. The life cycle for a keyboard with reader unit is to be increased and ensured with simulation.

Summary

Task

For the specific stress of the individual keyboard elements, it is necessary to ensure an optimal life cycle of the components.

Solution

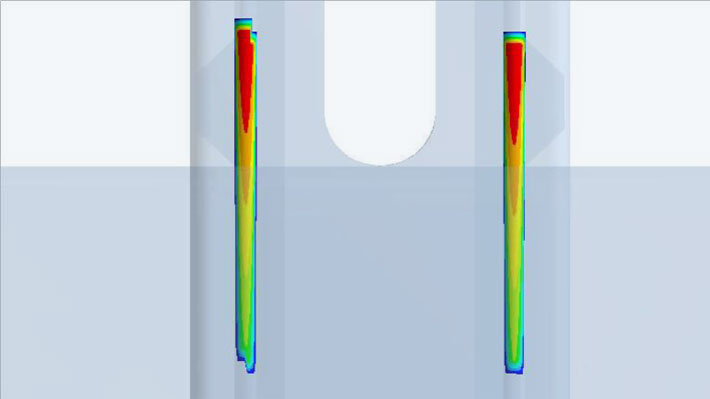

The life cycle analyses were carried out using a structural-mechanical FEM simulation of the keyboard stroke with Ansys Mechanical. In particular, the deformations and stresses under load were examined.

Customer benefits

The simulation results were directly implemented by DESKO in design changes, so that an optimal reliability and life cycle was immediately achieved. In this case, the previously conducted time-consuming tests with the keyboard elements could be completely eliminated.

Project Details

Task

For more than 30 years, DESKO GmbH has been developing hardware for reading documents such as ID cards, barcodes, magnetic stripes and chip cards. These reading devices are often integrated into keyboards in order to combine automated data checking and entry with manual data entry, for example in government offices, banks and airports. Since the requirements in everyday use can vary greatly, depending on the application, these must be taken into account as early as the product development stage. Among other things, this applies to the specific stress on the individual keyboard elements. DESKO reacts flexibly to the most diverse requirements of customers in order to ensure an optimal life cycle of the individual components of the comprehensive product portfolio.

Customer Benefit

The simulation results were directly implemented by DESKO in design changes, so that an optimal reliability and life cycle was immediately achieved. In this case, the previously time-consuming tests with the keyboard elements could be completely eliminated. The use of the software-on-demand offer eCADFEM (www.ecadfem.de) enabled an easy entry into simulation for DESKO, allowing for independent analyses of further variants. The quick implementation in daily business life and the adaptation to further constructive questions were ensured with the handover of the pilot project and the training based on it.

Solution

The life cycle analyses were carried out using a structural-mechanical FEM simulation of the keyboard stroke with Ansys Mechanical. In particular, the deformations and stresses under load were examined. The main focus was on the analysis of the nonlinear contact situation between the keyboard elements and the respective duct. Depending on the design, a different force curve at the contact surfaces results, leading to a different life cycle. Subsequent comparative analyses simplify the identification of the best variant in each case, which meets the various requirements.

Images: © DESKO GmbH