Using simulation for more efficient development work and a faster development process – for greater product innovation and improved product quality. Discover what simulation can do for your company too.

That’s why simulation pays off

Simulation isn’t an end in itself. Simulation’s full potential for a company is revealed when viewed from three perspectives. First, from the point of view of the designer or development engineer using the software in their everyday work. This gives rise to significant benefits for the development process as a whole. Entrepreneurs and product managers, meanwhile, see the added value that simulation has to offer above all else in the company’s higher product quality, quicker product availability and increasing innovative strength.

Cut development costs

Shorten development times

Overcome complexity

Promote innovation

Avoid product risks

Increase product quality

The potential of simulation from three perspectives

CADFEM three-perspective model

“Development work” perspective

"Development process” perspective

“Product” perspective

Potential for development work

Working with a digital prototype enables designers and development engineers to

• evaluate concepts and conduct feasibility studies at an early stage before commencing product construction.

• run through and optimize various load scenarios, geometry variants and material combinations.

• visualize product properties and improve their understanding of technical interdependencies.

• analyze how all the components interact and develop system descriptions.

Virtually all our customers confirm that working with a digital prototype creates a whole new level of understanding of the product properties and uncovers hidden potential for improvement.

Potential for the development process

Thanks to simulation, the key development work can be carried out using a digital prototype before a real one is made. This aids the development process in two ways:

• fewer loops in the product development process

• fewer trials and prototypes

Creating a close cooperative relationship between simulation and trials creates knowledge and understanding synergies. Not only does this lead to valuable findings; it also cuts costs and shortens development times in the long run.

Potential for the product

Ultimately, even the product itself benefits from simulation – as does its position on the market. Running through new ideas and analyzing numerous load scenarios particularly aids in

• tapping into new technical potential in existing products,

• designing new product innovations,

• safeguarding products’ quality and

• shortening development times. The product is thus available earlier and the company can respond to customer requirements more quickly.

All of these aspects ultimately lead to the product having a better competitive position on the market.

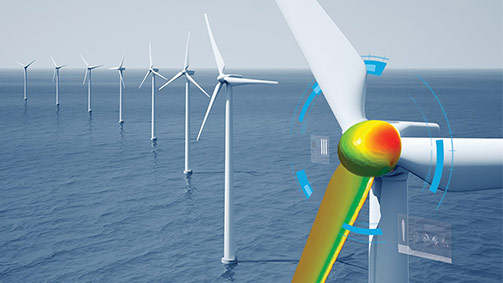

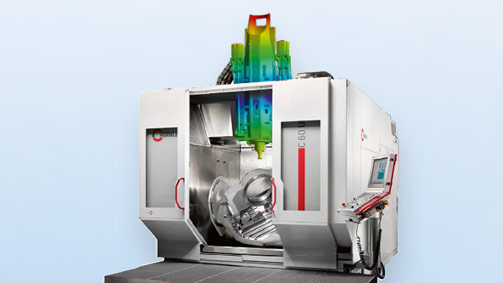

What is a digital prototype?

Understanding, further developing and optimizing a product before it’s even been built – all of this is possible with the digital prototype.

Prof. Sandro Wartzack, who also holds a PhD in Engineering and is Chair of Engineering Design at Friedrich-Alexander University of Erlangen-NurembergIf a product development process has to be faster, more affordable and more innovative, then simulation is the method of choice. And if you want to test the limits of what’s technically feasible, simulation is absolutely indispensable.

Nowadays, technical products are designed and built in a CAD system – so the geometric data is available in digital form. Simulation gives this data physical and technical properties, while defining load scenarios at the same time. The pure geometry is thus turned into a virtual – i.e. digital – prototype.

The digital prototype is the logical next step in the digitalization of development work and offers new opportunities for the further development of existing development processes.

Introduction of simulation in your company

We would be delighted to advise and guide you through how to efficiently introduce simulation software and processes according to our tried-and-tested four-step model.