Simulation on behalf of MOLL Automatisierung GmbH

Sector: Machinery and plant engineeringSpecialist field: Structural mechanicsMOLL Automatisierung GmbH develops high-quality products for the automotive industry in the field of conveyor and automation technology. CADFEM was commissioned to simulate the loads on the hangers with Ansys Mechanical and to make suggestions for the optimization of the product lifetime.

Summary

Task

A service life assessment was carried out to ensure that the hangers can withstand the repetitive loads. In this context, CADFEM was commissioned to identify possible weak points of the transport hangers and to carry out corresponding service life assessments using numerical simulations.

Solution

CADFEM carried out structural mechanical simulations with Ansys Mechanical. In particular, the use of different materials, the notches caused by the design as well as the screwed and welded connections were taken into account.

Customer benefits

Components of the transport hanger that are subject to particularly heavy loads were identified at an early stage and modified even before the practical test. The number of tests was reduced and the required service life could be proven accordingly.

Project Details

Task

MOLL Automatisierung GmbH develops high-quality products for the automotive industry in the field of conveyor and automation technology. This also includes hangers for the transport of car bodies through the production process. Due to the large number of different car bodies, the transport hangers, which are subject to high loads, are adjusted according to the current requirements. A service life assessment should be carried out to ensure that the hangers can withstand the stresses that often occur repeatedly. In this context, CADFEM was commissioned to identify possible weak points of the transport hangers and to carry out corresponding service life assessments using numerical simulations.

Customer Benefit

The simulations carried out by CADFEM enabled the particularly heavily stressed components of the transport hanger to be identified at an early stage and modified to suit the load before the first practical test. Thus:

- the number of time-consuming and costly tests could be significantly reduced and

- the required service life can be successfully demonstrated, so that the planned use in automotive production with the corresponding proofs was carried out in due time.

Solution

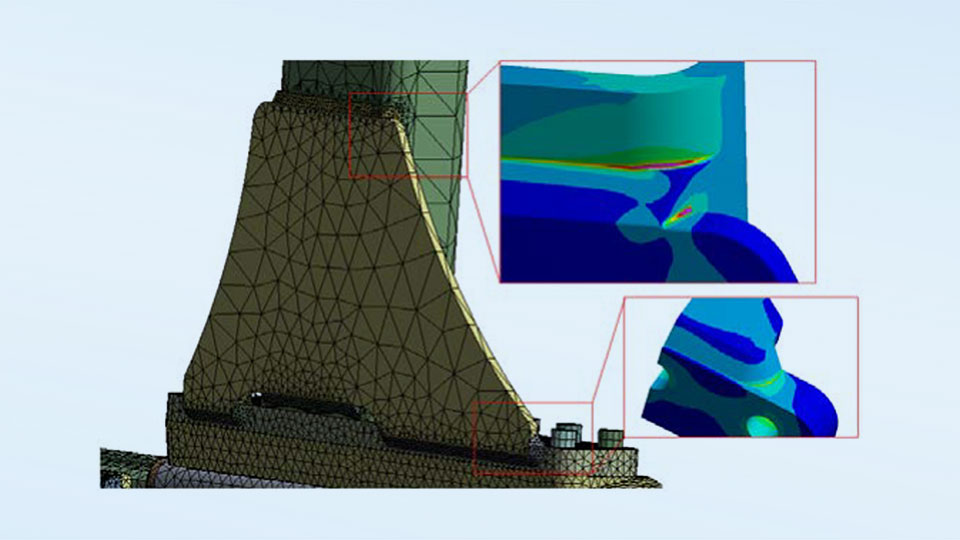

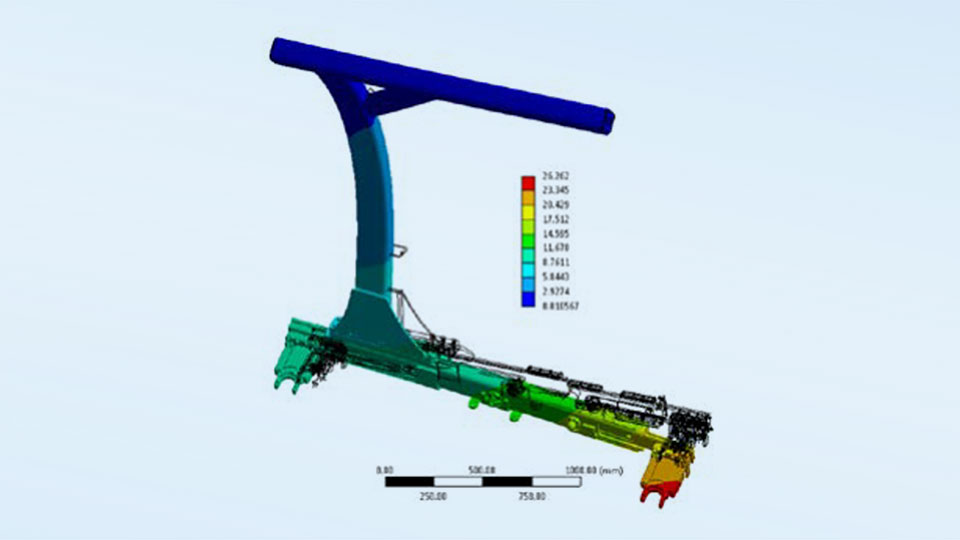

Structural mechanical simulations were carried out with Ansys Mechanical for the transport hanger shown in Figure 1. The following aspects were especially considered:

- the use of different materials,

- the notches caused by the design and

- the screwed and welded joints.

Depending on the substructure, different sets of rules were used for the service life assessment. The evaluation of the bolted connections was carried out according to VDI Guideline 2230 and the FKM Guideline was used for the verification of the welded connections. Structural stresses and local stresses were obtained from the simulation as input variables for the service life assessment.

Images: © MOLL Automatisierung GmbH