From small engineering offices to medium-sized family businesses, universities or large international corporations - simulation is successfully used in a wide variety of industries & companies. Here you can learn how!

How our customers develop groundbreaking innovations with simulation

There's no question about it: Simulation makes a great deal possible in product development. And the potential that lies in it is becoming ever greater. However, buying simulation software is usually not enough to achieve the best results. Many of our customers therefore combine several components from our portfolio of software and IT solutions, services and know-how transfer. Here we present examples that show how different customers use the CADFEM offering individually for themselves.

Reference Customers

Simulation is more than software. Only the individually optimal combination of products, service and knowledge leads reliably to success. Here we present some of our customers and show how they use our portfolio for themselves.

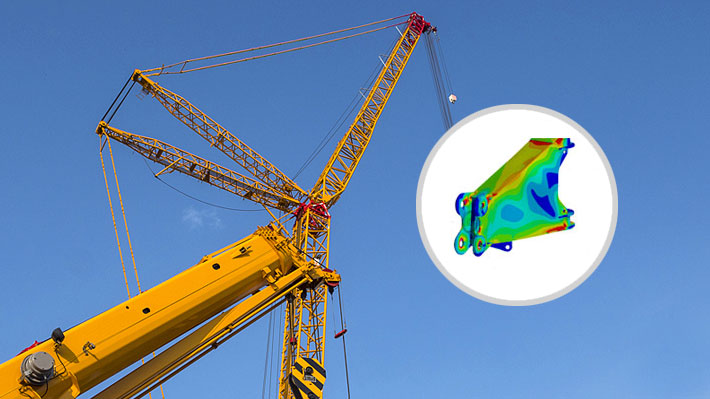

Liebherr pushes technical progress by using simulation

The wide range of products offered by Liebherr's 13 business units represents decades of experience and a high level of expertise. For simulations, the company relies in all product areas on Ansys and CADFEM.

Liebherr is not only one of the world's largest manufacturers of construction machinery, but is also successful in many other industries. The exchange between the business sections promotes innovative ideas and cross-sector developments. In this way, the nearly 50,000 employees create technological progress, also by using simulation solutions from Ansys and CADFEM.

More about LiebherrSEW simulates drive components and systems

SEW has been using CADFEM simulation solutions for 30 years to bring motion to almost all industries with its advanced drive technology. With these solutions, it can be more particular about its testing.

SEW-EURODRIVE and CADFEM have a long and intensive partnership. In addition to ANSYS software, SEW also uses a range of CADFEM services. For example, CADFEM is repeatedly called on to perform simulations on behalf of SEW in order to help ease capacity issues. Additionally, CADFEM training is held – both for new SEW employees and advanced users looking to learn more.

More about SEW-EURODRIVEMiele simulates to achieve premium quality

“Forever better” is Miele’s motto. CADFEM’s simulation solutions are indispensable for the engineers. It allows them to drive innovation forward and always stay one step ahead of the competition.

“Forever better” is the brand promise of the long-established Miele company. At Miele, quality, technology, comfort and design have always been the most important product development goals. Nowadays, Miele engineers use powerful CADFEM simulation solutions to drive innovation forward, to optimally design components and assemblies and to safeguard the diverse products’ functions.

More about MieleHilite – using simulation to drive product development forward

Hilite uses CADFEM’s simulation software to drive the development of components and modules for the automotive industry forward. So, they’re always one step ahead of the competition.

At Hilite, the use of simulation is an integral part of product development activities and covers a wide range of physical disciplines, including structural mechanics, electromagnetics, fluid dynamics analysis and system simulation. Hilite aims to optimize the factors of its products that are critical to their success, such as quality, reliability or service life, and thereby to improve its competitiveness.

More about HiliteOne for all

Endress+Hauser has been using computer-aided simulation to develop optimum solutions and products for 25 years. This includes optimizing the sensor in the Liquiphant M series point level switch.

Endress+Hauser and CADFEM have enjoyed a close cooperative relationship for 25 years. Having started with simple structural mechanics simulations, the entire functional spectrum of ANSYS is now used at Endress+Hauser for process sensor simulation. Together with complementary software, simulation with ANSYS Workbench accompanies all phases of the product lifecycle.

More about Endress+HauserCreating an enjoyable showering experience is Hansgrohe’s top priority

Hansgrohe relies on CADFEM simulation software to make showering an experience of wellbeing. It also uses the further training options to develop highly skilled junior staff.

Hansgrohe has been using numerical simulation as a CADFEM customer for more than a decade to reduce the time and effort needed for product development. The simulation disciplines for this are mastered using ANSYS tools, enabling fluid and structural simulations to be coupled, with optimum interfaces to the existing CAD system.

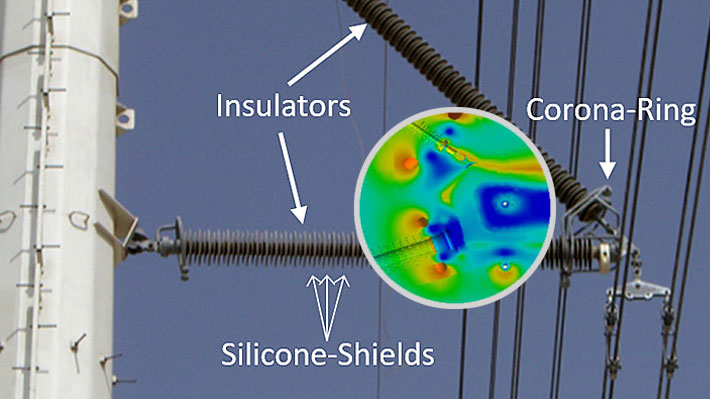

More about HansgrohePFISTERER uses silicone for insulation purposes

Silicone insulators for high-voltage cable connections are subject to special requirements. Pfisterer has specialized in this field and relies on CADFEM simulation solutions.

To exploit all the possibilities that ANSYS products offer for development tasks, PFISTERER attaches a great deal of importance to continuously establishing and building on simulation knowledge. Particularly in sensitive applications, silicone is a challenging material that requires the highest level of specialist knowledge and expertise. This is also reflected in the simulation work that accompanies the development process.

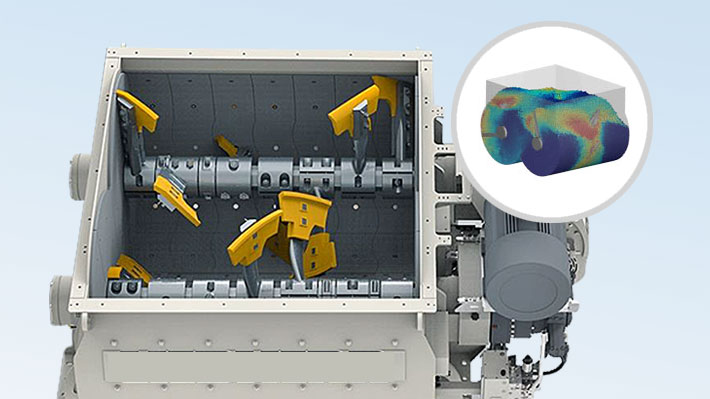

More about Pfisterer Holding AGHermle simulates for maximum precision

Hermle AG helps achieve milling at its best. Its machining centers have been constantly improved thanks to CADFEM simulation technology. This also makes for faster machine development.

Hermle AG was convinced by the ANSYS Workbench software following an extensive test phase due to its simple and intuitive user interface, fast and automatic mesh generation, short simulation times and good value for money. Besides the software, Hermle avails itself of various services offered by CADFEM, including consulting, to get the most out of simulation.

More about Hermle AGWeight-watching with ar engineers

Efficient work is the top priority for ar engineers GmbH. It uses ANSYS software to simulate material behavior under various scenarios, precisely and without undue expense or effort.

Design, simulation and implementation of composite projects is a core business area in the engineering and development consulting services offered by CADFEM’s customer ar engineers GmbH. Lightweight construction plays a major role for many clients in the aerospace, shipbuilding, automotive and wind power industries, to name but a few examples – when designing pleasure craft, for instance.

More about ar engineers GmbHAXA optimizes the stiffness of traveling column machining centers

AXA uses ANSYS Workbench to design and engineer bespoke production systems. CADFEM Support engineers are quick to provide assistance with complex simulations.

The intuitive operation, good project organization and comprehensive technical service were especially critical for AXA in its selection of the ANSYS Workbench simulation solution. AXA mainly performs simulations in the area of structural mechanics, as well as vibration analyses and simple temperature field simulations.

More about AXA Entwicklungs- und Maschinenbau GmbHBraun simulates for optimized operating behavior

Dr.-Ing. Ernst Braun GmbH has been relying on simulation software since 1991. It is convinced by the time savings and accuracy of the results in its development of rotating electric machines.

The Dr.-Ing. Ernst Braun GmbH company has been working closely with CADFEM for many years. ANSYS Maxwell, knowledge transfer, user support and comprehensive services available any time as needed are also key to the team’s enduringly successful use of its simulation technologies.

More about Dr.-Ing. Ernst Braun GmbHHEWI simulates comfort and accessibility

ANSYS simulation technology influences how HEWI products are developed – from the initial idea to series production. It’s turning premium quality and accessibility into the norm.

HEWI has been using ANSYS since 2002. At HEWI, experimental development activities accompany the entire product development process – from the initial idea to series production, and from feasibility studies in advance through to optimizations on virtual prototypes. As a result, HEWI needs far fewer costly and time-consuming physical prototypes.

More about HEWIHiller optimizes decanter centrifuges

Hiller decanter centrifuges are in demand the world over. Energy efficiency, lightweight design and higher speeds are the aims. These are achieved with the ANSYS simulation solutions in cooperation with CADFEM.

Hiller has relied on the ANSYS simulation software and maintained a close cooperative relationship with CADFEM since 2014. “Since CADFEM is known for simulation expertise and its ANSYS software has been established on the market for decades, we initially started a consulting project to conduct a modal analysis of our decanter centrifuges,” says Robert Wagenbauer, recalling the successful start to the companies’ collaboration.

More about Hiller GmbHKlubert + Schmidt simulates exhaust flaps

Klubert + Schmidt relies on ANSYS AIM in exhaust flap development. The simulation software for multiphysics simulations impresses with its intuitive ease of operation and user-friendliness.

When the Klubert + Schmidt designers decided to take the next step in product development, they initially thought of having simulation software integrated into their CAD system. After CADFEM presented the possibilities of ANSYS Discovery AIM, its new multiphysics simulation software, they were won over by the advantages of this far more powerful solution.

Mehr zu Klubert + SchmidtKomatsu Hanomag simulates construction work

Excavators have to withstand a great deal on a construction site. CADFEM simulation technology plays a major role in the entire product development process to prepare them for these requirements.

Calculation tasks are becoming ever more complex and the software requirements are also growing as a result, which is why the Hanover-based KOMATSU HANOMAG construction machinery engineers turned to the simulation specialists at CADFEM. “CADFEM was able to demonstrate to us quickly and comprehensibly how to use ANSYS Workbench, using our own tasks as a basis.”

More about Komatsu HanomagMR automates the simulation of screw connections

MR is known for its highly durable on-load tap-changers. This is mainly thanks to the design of the screw connections, which was developed with the help of CADFEM simulation technology.

Maschinenfabrik Reinhausen and CADFEM as an ANSYS Elite Channel Partner have a close cooperative relationship. For example, complete calculation tasks can be transferred to CADFEM if MR’s staff capacities are insufficient. CADFEM also holds project-related training courses to enhance the efficiency of MR’s simulation applications.

More about Maschinenfabrik ReinhausenWITTUR simulates elevator machines

Wittur Electric Drives GmbH aims to make elevator travel as comfortable as possible. It relies on CADFEM simulation solutions for this purpose.

Wittur chose CADFEM as the solution partner for all simulation questions and the ANSYS Maxwell software. Crucial to this was the fact that ANSYS supports several physical disciplines. Witter’s team was also impressed by CADFEM’s range of simulation services and the quality of support even during the test phase – particularly the provision of intense training and user support.

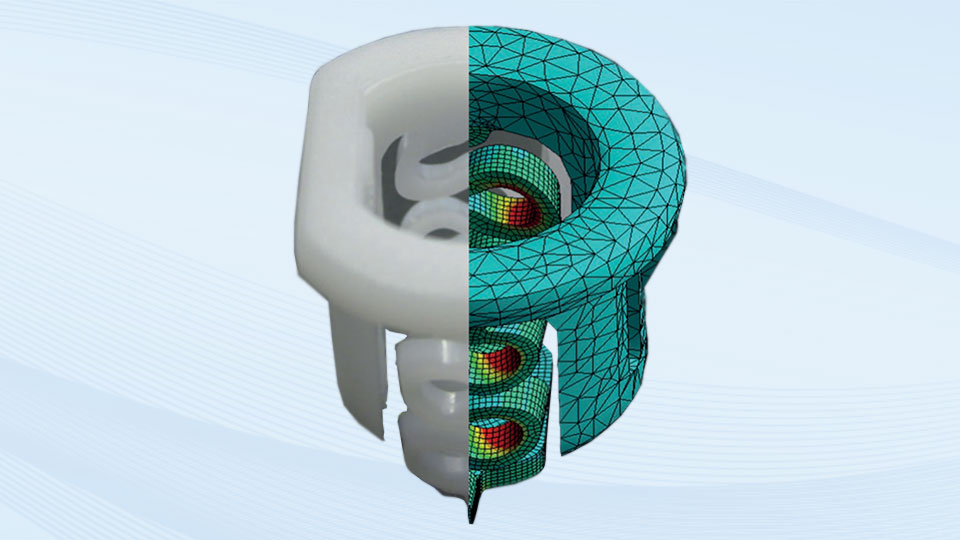

More about Witturulrich medical gives doctors a strong backbone

Screws in the human spine and other bones are subject to special requirements, which ulrich medical meets with an extremely high degree of precision using CADFEM simulation solutions.

As is the case with all development processes, one thing remains unknown, even when creating innovative medical products: possible problem areas could be identified too late, thus resulting in costly corrections. ulrich medical, an Ulm-based company with a long-standing tradition, is reducing this risk by performing simulations with Ansys during the development process that are validated with advice and support from CADFEM if necessary.

More about ulrich medicalCarabiners for climbers: safe thanks to simulation

As a specialist supplier for mountain sports, EDELRID also develops carabiners. Simulations are used to achieve the essential requirements: safety and low weight.

Structural mechanics simulations are an essential part of the development of safety-critical products for climbing at EDELRID. As they are used in a very targeted manner, those responsible have opted for demand-oriented use according to the prepaid principle. The Ansys licence is only activated (and paid) via the eCADFEM service when it is needed.

more about EDELRIDActive mobility

provided by the start-up CIXI.

CIXI is a start-up that aims to transform passive daily trips into moments of chosen effort. The VIGOZ, the first approved active vehicle, was developed with Ansys LS-Dyna.

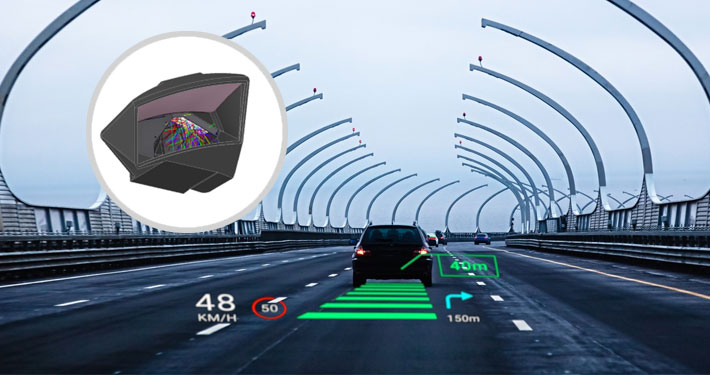

Details on the CIXI reference customerAugmented reality for road safety by EyeLights

Founded in 2016, EyeLights develops and markets head-up display systems that propel augmented reality directly into the field of vision of motorcyclists and motorists.

While the first developments were successfully carried out using a traditional approach to design, prototyping, experimentation and measurement, management decided to turn to digital simulation in order to accelerate its development cycle, and therefore its time-to-market, which is crucial for a start-up.

Details on the Eyelights reference customerWhat our customers say about us

Satisfied customers are the best reference. Read here a small excerpt of customer testimonials from various industries with different requirements with whom we successfully cooperate.