Using ANSYS for stress analysis conforming to AD 2000 S4

Sector: Machinery and plant engineeringSpecialist field: Structural mechanicsOn behalf of Chemieanlagenbau Chemnitz GmbH (CAC), CADFEM carried out an analysis of a branch connection used on an absorber tower as found within a sulfuric acid plant, with CADFEM also processing the data for the purposes of assessment according to AD 2000 S4.

Summary

Task

When it comes to the design of a whole variety of plant systems, the instruction sheets that are most often used are those published by the German pressure vessel association (the AD), designated AD 2000. The requirement was for a simulation-based analysis to be carried out for a branch connection in conformity with this standard.

Solution

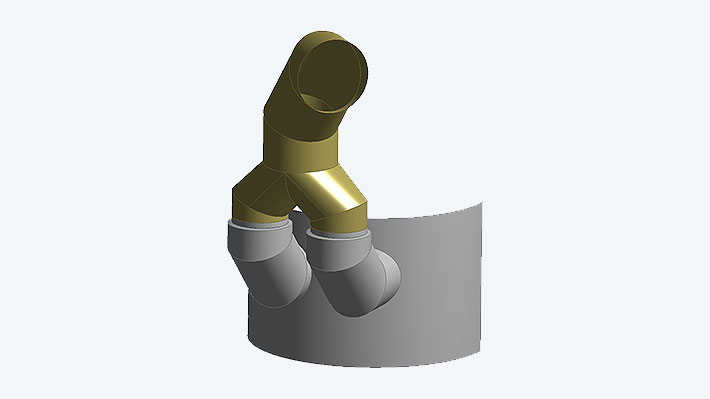

The branch connection and a section of the absorber tower were modelled, and a shell model was created – all on the basis of technical drawings. ANSYS subsequently provided verification according to AD 2000 S4.

Customer benefits

Applying CADFEM’s recommended approach to shell models facilitated direct determination of the linearized stress (both the membrane stress and the bending stress) across the cross section. Subsequent processing of the results formed the basis for direct verification of the structure in accordance with AD 2000 S4.

Project Details

Task

Large chemical plants often consist of separately located areas within which individual steps take place. The individual components, such as towers, boilers, or tanks, etc., are connected together via piping. External forces, internal pressure, and even temperature differences represent common load types in this context. When it comes to the design of a whole variety of plant systems, the instruction sheets that are most often used are those published by the German pressure vessel association (the AD), designated AD 2000. On behalf of Chemieanlagenbau Chemnitz GmbH (CAC), CADFEM carried out an analysis of a branch connection used on an absorber tower as found within a sulfuric acid plant, with CADFEM also processing the data for the purposes of assessment according to AD 2000 S4.

Customer Benefit

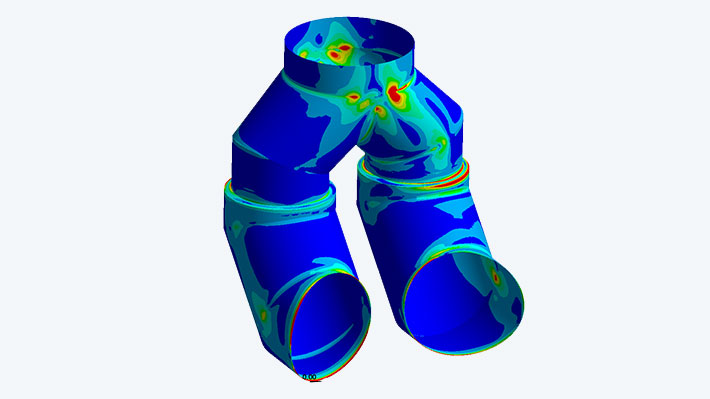

The results provided a global overview of the total deformation and the distribution of stress within the structure. It was possible to perform a localized assessment of areas that were either difficult to access or completely inaccessible for the purposes of analysis (e.g., along a predefined path). When shell models are used, it is possible to achieve direct determination of the linearized stress (both the membrane stress and the bending stress) across the cross section. Subsequent processing of the results formed the basis for direct verification of the structure in accordance with AD 2000 S4.

Solution

The branch connection and a section of the absorber tower were modelled, and a shell model was created – all on the basis of technical drawings (see illustration). Weld seams were not included in the modeling process. “Carving out” part of the overall structure required the application of meaningful boundary conditions at the rims of the border tower, with forces, moments, and constant internal pressure all acting on the structure. A linear elastic analysis of the stresses was performed, as required by the AD 2000 code of practice.

Images: © CAC – Chemieanlagenbau Chemnitz