Robotic hoist system secured and certified with Ansys

High Performance

With the robotic hoist system LIFTBOT, the start-up KEWAZO has developed a smart alternative to traditional approaches. It saves an enormous amount of time and costs and improves work safety thanks to automation and maximum flexibility. This technically advanced system was designed by KEWAZO with Ansys. It was also certified with Ansys, which happens to be used by the TÜV (German Technical Inspection Association).

Digitalization has long steered clear of many products. These include scaffolds and lifting equipment, such as the classic hoists used in construction. Not only do they require a lot of space and installation personnel, but they also require a high-voltage power supply, preliminary static calculations and complex logistics. This is why they are generally only used when the builder explicitly wants them and also pays for their use.

Graduates of TU Munich recognized early on that there was great potential where these prior methods fell short. In 2018, they founded the start-up KEWAZO to develop modern solutions. Today, companies such as Bilfinger, Altrad and plant operators such as BASF or ExxonMobil are among the customers of the Munich-based company.

But first things first. KEWAZO's vision was to exploit the untapped potential of automation and digitalization in the construction industry. Not in the planning offices - where it has long been established - but rather at the actual construction site, where scaffolding needs to be erected and materials transported in order to realize construction or renovation projects. .

LIFTBOT: Construction Logistics 4.0

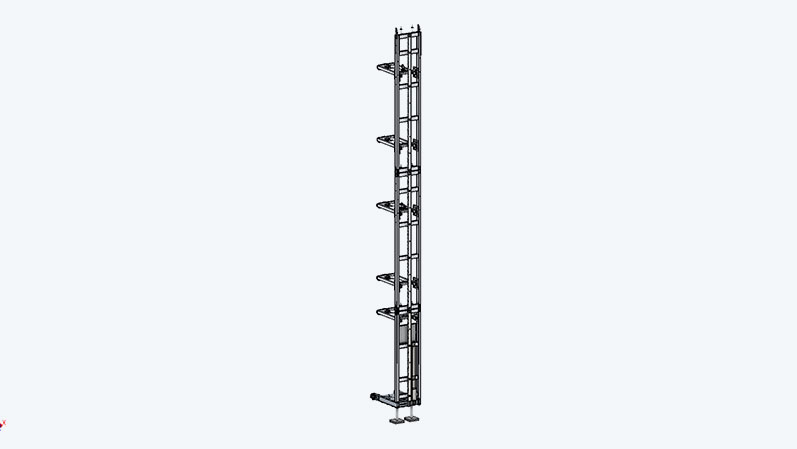

LIFTBOT is the first robotic hoist system that automates the transport of materials on construction sites. The first application was quickly found in scaffolding, where 80% of all projects today are still done manually. LIFTBOT revolutionizes construction logistics with digital methods, saving up to 70% of labor costs. Additionally, the construction infrastructure is often in place twice as fast as usual and is safe for both the builder and the environment.

This is made possible by the smart combination of intelligent automation, flexibility and the use of state-of-the-art technologies. Because LIFTBOT is compact, mobile and wireless, there are also hardly any restrictions with regard to the place of use. Last but not least, LIFTBOT collects operational data and makes it available in the form of a data analytics platform, enabling more proactive project management.

Aim and ambition: reliable, simple and ergonomic precision

Robotic systems such as LIFTBOT require maximum precision in the areas of mechanics, electrics and software and, of course, their perfect interaction. The KEWAZO “Mechanical Engineering & Product Design” team is responsible for

- … the maximum safety and reliability of the design and all components. These components operate at great heights and in the presence of people, requiring many contingencies to be taken into account.

- … a light weight of the product itself. Every kilo saved - by design or the choice of materials - increases the transport capacity.

- … an ergonomic use of the system. Efficient processes and an energy-saving, human-oriented mode of operation are the keys.

Proof of Performance: TÜV Süd certified with Ansys

To achieve this, KEWAZO relied on Ansys from an early stage. Initially via an external partner, then with CADFEM. Why Ansys in particular? Because not only did the external service provider use it, but TÜV Süd also uses it for certifications. When the first version of LIFTBOT was launched, TÜV Süd, KEWAZO and the CADFEM specialists for Ansys worked closely together. The associated know-how transfer from CADFEM to KEWAZO has enabled the start-up to independently solve many and very ambitious use cases with Ansys today.

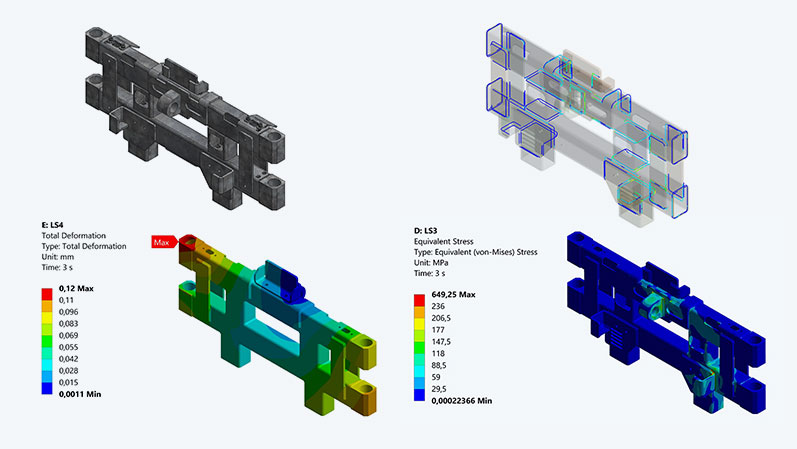

KEWAZO uses the start-up version of Ansys Mechanical, in addition to the CADFEM extensions “Bolt Assessment inside Ansys” and “FKM inside Ansys” for mandatory verifications. The benefits of in-house simulation expertise are the speed at which different design options can be objectively compared, with a significantly reduced need for real prototypes. Certification is also more effective thanks to the detailed documentation of results and data consistency with the TÜV.

Aleksandar Belberov, Head of Mechanical Engineering and Product Design, KEWAZOThe projects with CADFEM have opened our eyes. We realized that simulation with Ansys needs to be firmly embedded into our design process.

Typical use case

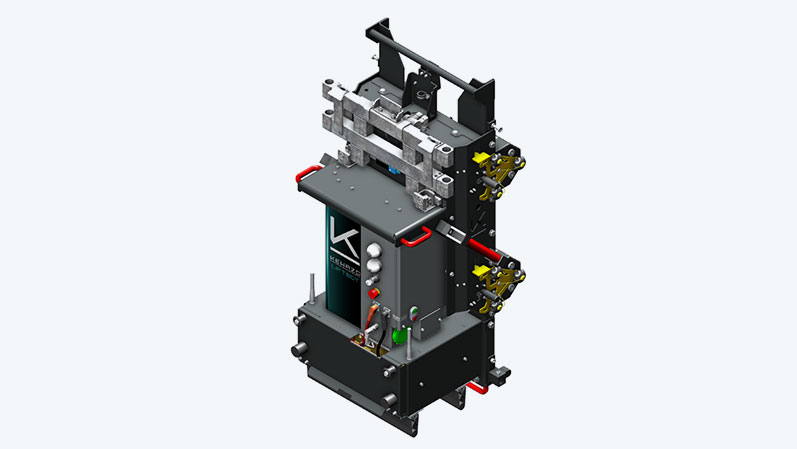

How is Ansys used at KEWAZO? An example shows this at the interface between 2 of the 3 main components of the LIFTBOT:

- The Robot Module (RM) is the actual robot (the control center and brain of the system).

- The Transportation Platform (TP) is the support device on which the material rests and is configured very differently depending on the task.

- The Rail System (RS) is the rails on which the robot moves.

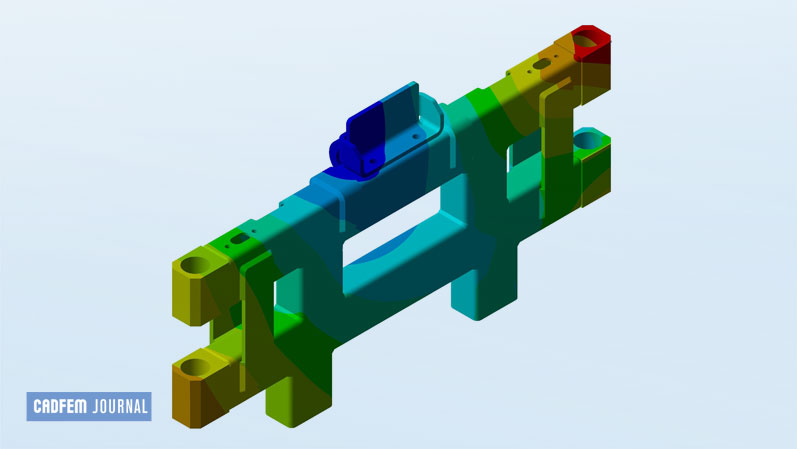

The RM includes a steel frame made from pipe profiles, sheet metal parts and CNC-manufactured precision components that support the TP. Most parts are welded, while safety-critical connections are bolted. The frame is designed to absorb the mass from the material and platform and pass it on to the RM resting on the rail. It also indicates overloads and collects data for process analysis. Since the frame is subjected to highly variable loads, certification requires a particularly accurate structural-mechanical analysis. It was therefore subjected to a separate analysis. This was carried out together with CADFEM and led to the successful certification of the LIFTBOT.

The KEWAZO team later revisited the assembly on their own to find material alternatives to the previous steel, which was expensive and difficult to weld. This proved to be a complete success. The new material not only drastically reduced manufacturing costs, but also the weight by 20%, in part because the steel could be partially replaced. A simplified assembly, fewer tolerances at the interface and improved calibration of the overload system were also achieved. The TÜV accepted the result report again on the first try, allowing this optimized version of the frame to go into series production.

The immense advantage of being able to run simulations independently also became apparent. The possibility and freedom to try out alternatives quickly, easily and above all reliably is of inestimable value in terms of quality, innovation and costs!

Aleksandar Belberov, Head of Mechanical Engineering and Product Design, KEWAZOThe entire system structure was simulated with Ansys - solids, welds, fasteners, kinematics ... everything!

KEWAZO and CADFEM: Know-how Transfer Today and Tomorrow

Within a short time, KEWAZO has succeeded in carrying out sophisticated structural-mechanical simulations with Ansys in the development of the LIFTBOT. An important role has been played by the initial joint project work with CADFEM, which is designed to maximize know-how transfer.

And the partnership continues: in the short term for support issues, in the medium term for knowledge expansion (e.g., via the CADFEM Learning Subscription), and in the long term when it comes to opening up additional fields of application in simulation.

About KEWAZO

KEWAZO is a construction robotics start-up founded in Munich in 2018. The international team of 45 employees (2023) automates and digitalizes construction site logistics with robotic systems. KEWAZO solves the challenges around scaffolding construction such as labor shortages or the deficits in productivity and safety. In addition to the European market, KEWAZO is also present in North America. www.kewazo.com

KEWAZO

www.kewazo.com

Author: Alexander Kunz

(CADFEM Germany GmbH)

Cover Images: © KEWAZO

Published: September, 2023

Contact CADFEM