Automated report generation of Ansys results

Pretty fast

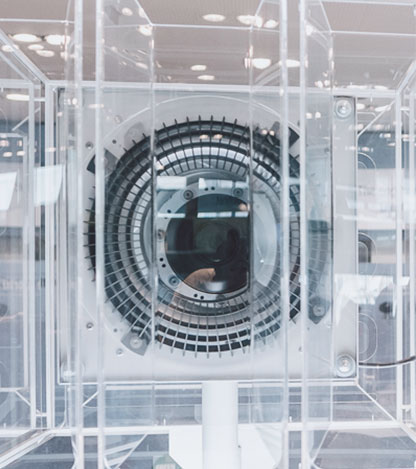

As the world’s leading manufacturer of fans and motors for ventilation and heating technology, efficient development processes are essential at ebm-papst. No wonder why simulations with Ansys are firmly anchored. For a long time, just documenting the results was considered tedious and time-consuming, until automation cut the effort for this in half and ensured a representative design.

What must be, must be. At ebm-papst, results of simulations and how they occur during the development processes for fans and ventilators are recorded in detail and documented transparently. After all, this is what describes the behavior of the individual components, the motor, the electronics, and the aerodynamics, and shows the ways in which these can interact optimally as an overall system.

The goal and aspiration of the world market leader from Mulfingen in Baden-Württemberg is to bring innovative and high-quality solutions with maximum performance to the market in short development cycles. Great importance is also placed on sustainable production and energy-efficient operation.

Simulations are used to test new ideas and approaches (innovation), identify and exploit additional performance potential (sustainability and quality), and bring products to market much faster (time-to-market).

Documentation is a must

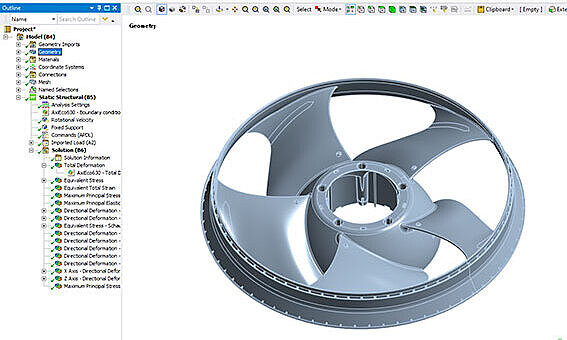

100 or more development projects go through a simulation process each year in Mulfingen alone. Each one requires a meaningful report according to specific ebm-papst specifications. The standard reporting function in Ansys is usually not sufficient for its creation. Reporting therefore takes up a lot of time - time that is lacking for the actual tasks, the simulations.

Tedious, time-consuming, unpopular

With a continuously increasing simulation volume and a growing simulation team in the development department of the world market leader, the unsatisfactory situation regarding the topic of reporting has gradually come into focus.

“Our highly skilled simulation professionals spent far too much time on report generation. In particular, searching for and integrating images, as well as manually adding text and handling the various data formats that make up the report has been a very tedious task,” says Martin Baer, team leader of the computational engineers in the structural mechanics department. “In the end, we were often left with the impression that the result was not really commensurate with the effort involved. The reports varied in form and sometimes even deviated significantly from the layout specifications.”

About ebm-papst

The ebm-papst Group is a family-owned company with headquarters in Mulfingen, Baden-Württemberg. A global leader in fans and motors, ebm-papst has been setting international market standards for over 60 years with its core competencies of motor technology, electronics, digitalization, and aerodynamics. Sustainable, intelligent, and precisely fitting solutions for virtually every requirement in ventilation and heating technology are in demand in many industries: from ventilation, air-conditioning and refrigeration technology to IT, mechanical engineering, intralogistics, and medical technology.

Simplification and freedom through automation

Eliminate hurdles, save valuable engineering time, and make the results more transparent through a complete and attractive presentation in the ebm-papst corporate design (CD). Martin Baer turned to CADFEM to implement his idea for an automated solution.

The reasoning: reporting is nothing more than a mandatory, standardized process with a defined goal. However, the clear line has been lost somewhat over the years and a certain uncontrolled growth has developed. This can be due to a number of reasons: tasks, requirements and formats change, tools become obsolete or are replaced, and in day-to-day business, it can be difficult to find the time to structure and coordinate everything from the ground up. Somehow it works, albeit with a lot of time, less motivation, and an expandable design.

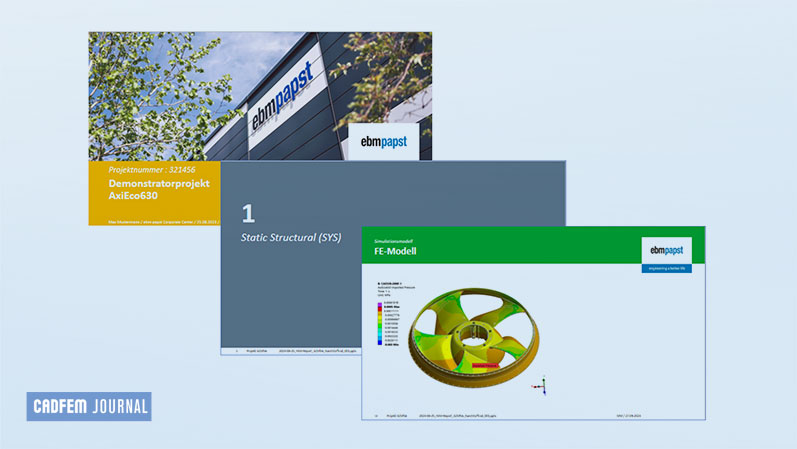

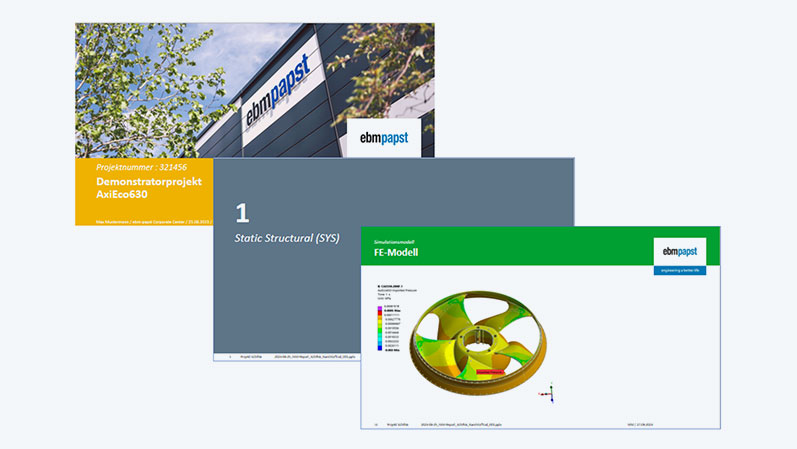

Martin Baer’s vision was a full report containing all relevant images, project, material, and result data, which is visually appealing and CD-compliant, and that can be produced in a much shorter time than usual. An extremely fast automated report generation!

Automatic image generation

- Complete Geometry

- Meshing

- Material

- Overview

- Boundary Conditions

- Result Object

- Transfer of Comments

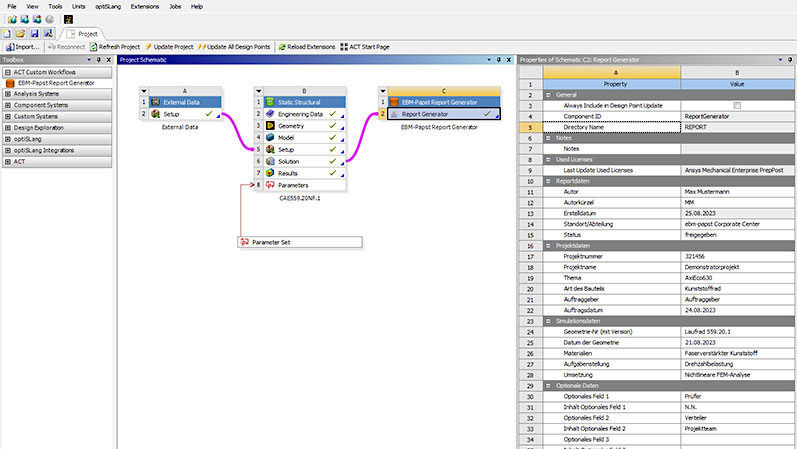

Intuitive and automated to the full report

- Structured: Analyses are separated by subchapters.

- Transparent: information included in the report is immediately visible.

- Reproducible: project data stored in the properties.

- Reusable: Stored data can be imported.

- Data management: one report is saved per design point.

Specifications and project plan

Martin Baer and Jürgen Herr from the St. Georgen site in the Black Forest formed the core team for this project on behalf of ebm-papst. In order to increase the transparency and acceptance of automated report generation, all other German locations were also involved, from the formulation of goals to the test phases. At CADFEM, Dipl.-Math. Susanne Haase led this project, supported by colleagues from CADFEM as well as inuTech GmbH, a CADFEM Group Solution Partner specializing in programming and automation.

Dynamic and cooperative project implementation

For the development of a customized solution to be successful, project partners must work closely together. The automation solution was therefore developed in an iterative process with regular meetings at which the project status, ideas, detailed goals, and the further timetable were discussed, checked and, if necessary, dynamically adapted. A small pilot project proved to be very helpful in this process in order to coordinate technical points before the final programmatic implementation took place.

The result, after 20 days of pure working time, was an extension based on the Ansys Customization Toolkit (ACT) with an input mask for higher-level project data such as order number and author, as well as selectable and deselectable options for the report. When report generation is started, the data and images are exported from Ansys Mechanical using IronPython and sent to PowerPoint via a .NET framework. A particular challenge was storing data in the project directory in order to keep the assignment of the reports to the different analysis systems on the Ansys Workbench project page traceable.

Thanks to clear ideas and cooperative implementation, this range of tasks was realized in about 5 months - from placing the order to handover of the results including source code and manual.

RESULTS: 50% TIME SAVINGS

The expectations for automation have been fully met. Not only are the results reports produced in half the time it used to take, but they are also visually consistent and 100% compliant with the corporate design of ebm-papst. The acceptance level of the tool is high; it pays off here that practically everyone affected at the German-speaking locations was involved in the development in advance. The next step will be to create versions in other languages.

Outlook

Since the automation is based on an ACT extension, it will also run stably in future Ansys releases. However, this does not mean that it will no longer change. Martin Baer and his team continue to collect ideas and requests to make the tool better and even more powerful.

The positive experiences with this project also provide inspiration for how other digital engineering processes at ebm-papst can be automated and customized using simulation.

ebm-papst has been using Ansys since 2008. The decisive factors were the user-friendliness, the wide range of applications (including multiphysics), and the easy connection to all common CAD systems. 10 full-time employees deal with structural-mechanical simulations alone. Some projects are outsourced to external service providers, and new topics are often worked on with universities. ebm-papst's partner for Ansys is CADFEM Germany GmbH, whose consulting, training, support, and customization services are used regularly.

ebm-papst

Martin Baer

ebm-papst

Author: Alexander Kunz (CADFEM Germany GmbH)

Cover Images:

Right:© ebm-papst

Left: © ebm-papst

Published: October, 2023

Contact CADFEM