Reliable force distribution during endoscopy

Sector: Medical technologySpecialist field: Structural mechanicsOvesco Endoscopy AG specialises in medical products for flexible endoscopy and endoluminal surgery. Its innovative main products include endoscopic clip systems (OTSC: Over The Scope Clip) made of Nitinol. To save expensive prototypes, an analysis workflow has been set up.

Summary

Task

The special functions and therapeutic effects are based on the special material and design properties of the OTSC system. The superelastic nitinol used is bio- and MRI-compatible and therefore also suitable for remaining in the body as a long-term implant. Nitinol prototypes, however, are expensive and time-consuming to produce.

Solution

The Nitinol material properties were mapped with the material law available in Ansys Mechanical and used to determine the assembly and extraction forces. By varying the design, the material characteristics or even the coefficients of friction, different assembly and application scenarios can be analysed.

Customer benefits

With the analysis workflow now available, the development process of new clip systems can be significantly improved and made more efficient.

Project Details

Task

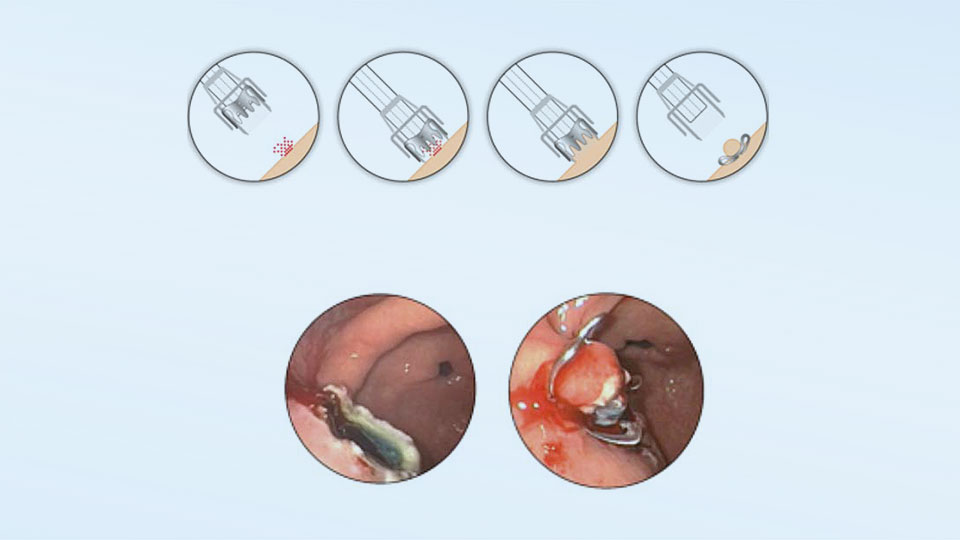

Ovesco Endoscopy AG specialises in medical products for flexible endoscopy and endoluminal surgery. Its innovative main products include endoscopic clip systems (OTSC: Over The Scope Clip) for the treatment of gastrointestinal bleeding and for endoscopic wall closure in the digestive tract. The special functions and therapeutic effects are based on the special material and design properties of the OTSC system. The superelastic nitinol used is bio- and MRI-compatible and thus also suitable for remaining in the body as a long-term implant. Especially the mounting of the clip in the endoscopy system as well as the application of the clip on the tissue require the highest mechanical reliability to avoid inconvenience during the surgical procedure on the patient.

Customer Benefit

With the analysis workflow now available, the development process of new clip systems can be significantly improved.

- Shorter development time: Quick information on important questions regarding clamping, actuating and clamping force.

- Cost reduction: Saving of expensive prototypes with high-quality and expensive material (Nitinol).

- Reliability: Greater fault tolerance when applying the clip due to a more robust design and thus greater reliability in operative use.

Solution

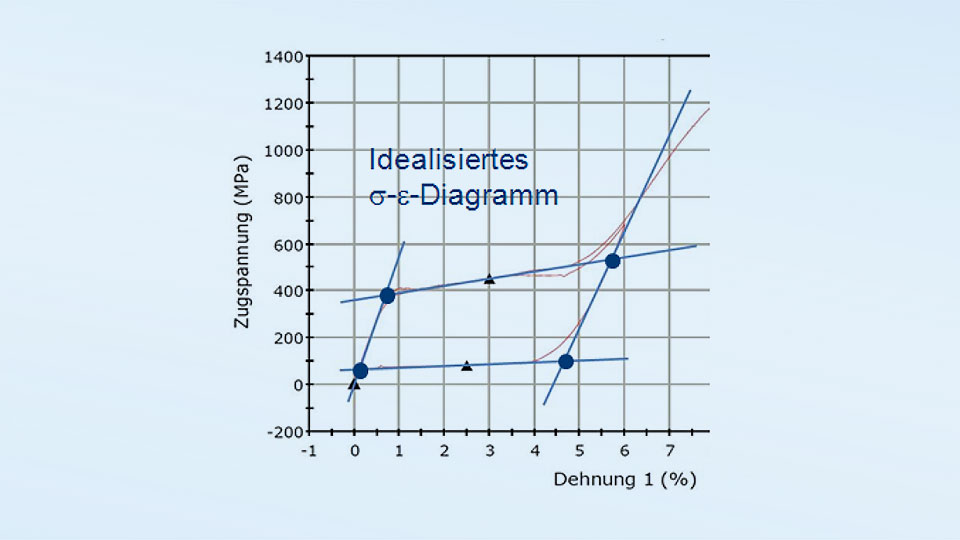

Due to its special properties as a shape memory alloy, nitinol is often used in surgical medical technology. In addition to the special characteristic of "remembering the initial state", this metal is distinguished above all by its super-elastic behaviour. As a result, high elastic strains can be endured without permanent deformation. This material property was mapped with the material law available in Ansys Mechanical and used to determine the assembly and extraction forces. By variation of the constructional design, the material characteristics or also the coefficients of friction between contact pairs, different assembly and application scenarios can be analyzed within the scope of a nonlinear static calculation. The model creation and analysis was carried out as a pilot project as an introduction to simulation while accompanying the development of the design.

Images: © Ovesco