Maschinenfabrik Berthold Hermle AG

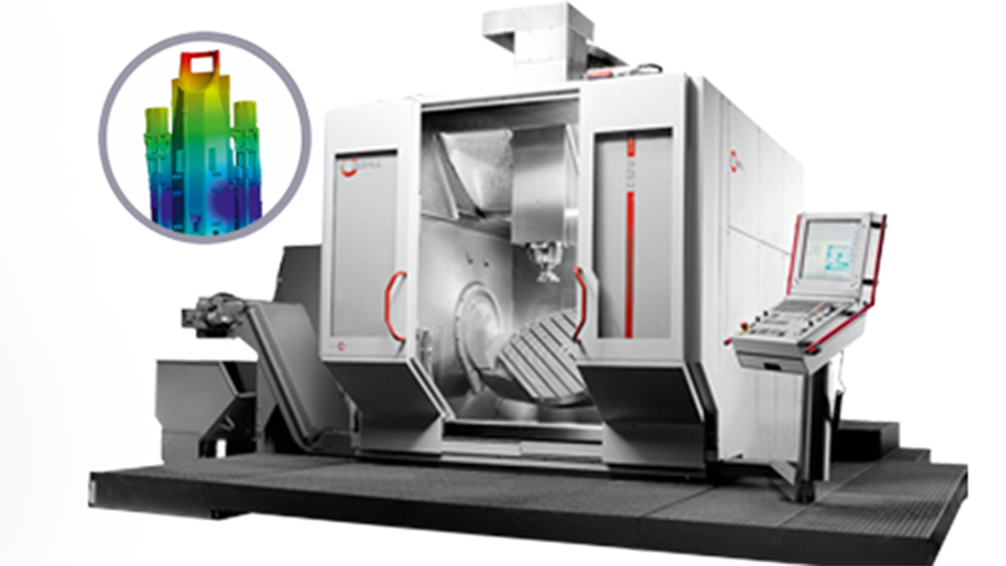

Hermle AG produces high-precision machining centers in keeping with this motto. It uses CADFEM simulation solutions in product development.

Hermle simulates for maximum precision

At Hermle, based in Gosheim on the edge of the Swabian Jura, everything revolves around milling and outstanding results. “Milling at its best” is also Hermle AG’s tagline, underpinning its high standards. The company is a leader both nationally and internationally with its machining centers.

But how is “milling at its best” made possible? The answer is essentially simple: through every single department within the company constantly searching for and rigorously implementing possible improvements. This has led to the use of modern simulation technology in product development, for example.

Hermle and CADFEM

Hermle AG has been working for more than a decade with numerical simulation based on the finite element method. The company gained initial experience by assigning simulation jobs to external service providers. Following good results, it soon made the decision to move simulation in-house.

Hermle was convinced by the Ansys Workbench simulation software following an extensive test phase due to its simple and intuitive user interface, fast and automatic mesh generation, short simulation times and good value for money.

Understanding complex mechatronic systems thanks to simulation

“We achieved notable successes with it after just a short space of time,” said Reiner Müller, Simulation Group Manager, in reference to that early simulation use. Today, Hermle has long been using a variety of simulation tools to analyze entire mechatronic systems of machine tools, including drives, controls, measurement systems and machine structures.

“Using simulations as a basis, we are often in a position today to understand the effect of complex systems and identify the key influencing factors. With the aid of simulation, overall machine quality has been improved and the time from the first draft design to delivery of the machine has been significantly shortened,” said Reiner Müller, summarizing the benefits for Hermle.

CADFEM training and further education

Besides the software, Hermle avails itself of various services offered by CADFEM, including consulting, to get the most out of simulation. It also uses CADFEM esocaet training and further education options.

“I was able to gain new experience on the course and pick up a great deal of background knowledge which I can effectively apply day to day in my simulation work,” said Benjamin Schwarzwälder, a computational engineer at Hermle who holds a Master’s in Applied Computational Mechanics, a course organized by CADFEM esocaet in collaboration with Ingolstadt University of Applied Sciences (THI) and Landshut University of Applied Sciences.

Products

Knowledge