Simulation Driven Development of a Drying Oven

Sector: Automotive (motor vehicles/trucks)Specialist field: Heat TransferWhile planning a new drying oven for the new Porsche 911 and Boxster in Stuttgart-Zuffenhausen, Porsche used VPS/DRY within the design phase of the new oven to simulate the paint drying process.

Summary

Task

In a car body painting process the body in white with the applied e-coat moves through an oven to dry the paint layer. The paint is damaged if the temperature is too high, and high temperature gradients lead to mechanical deformations. Simulation should avoid this in the conception phase.

Solution

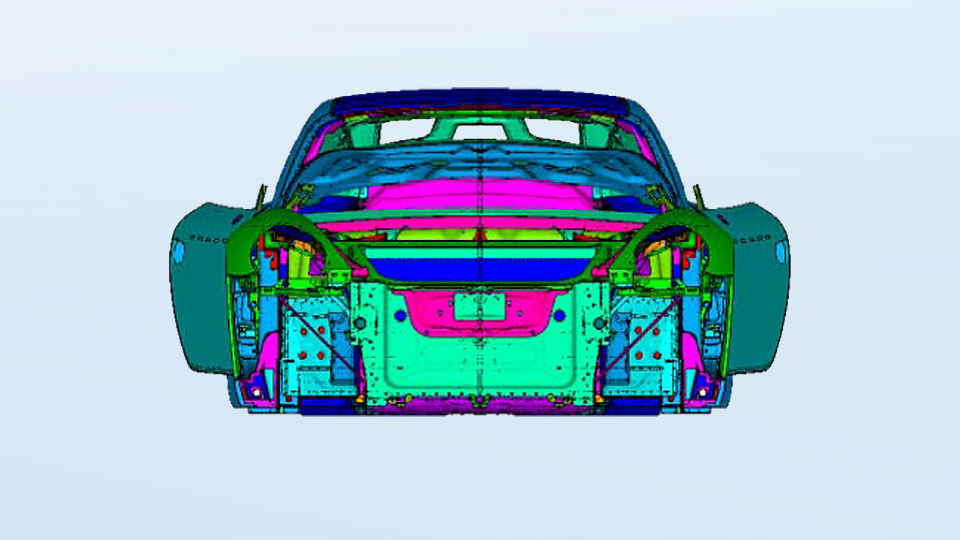

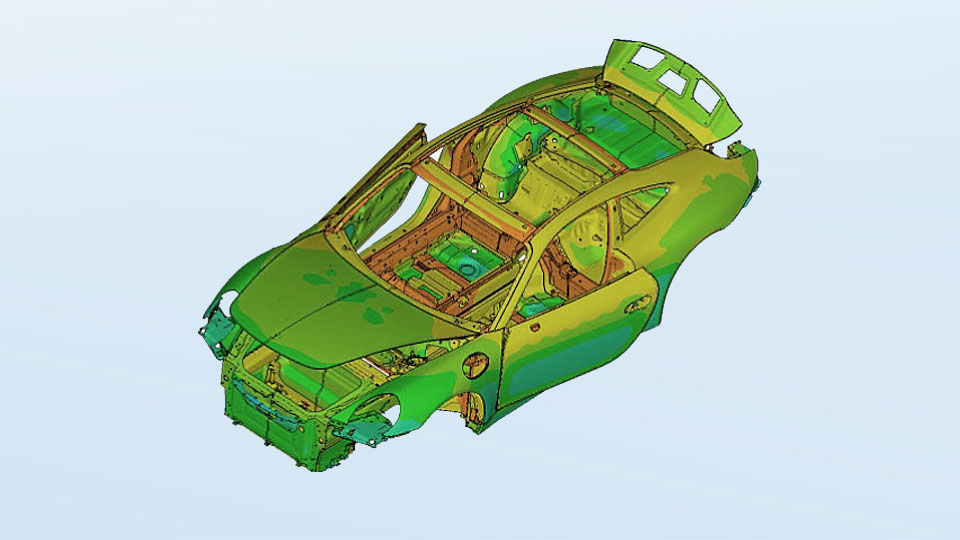

VPS/DRY analyzes the temperature distribution, the temperature dwell time and thermal deformations of the car body.

Customer benefits

Virtual technology helped to avoid expensive changes after the oven is built.

Project Details

Task

In a car body painting process the body in white with the applied e-coat moves through an oven to dry the paint layer. Besides drying the paint the oven is also used for:

- hardening of aluminum alloys,

- curing of adhesives,

- foam expansion.

High quality standards apply to the drying process of car body paints. These standards guarantee that all parts of the body in white reach a certain temperature over a specified time period and assure high quality paint application. On the other hand, the paint is damaged if the temperature is too high, and high temperature gradients lead to mechanical deformations. Additionally, the time available for the whole process is limited. Especially if aluminum and steel mixtures are used, thermal stresses, which could exceed the stress limits of the material and cause permanent deformations, should be evaluated.

Customer Benefit

With simulations of the oven behavior in the design phase, an optimized oven design was found which fulfills the required criteria of the drying process. Virtual technology helped to avoid expensive changes after the oven is built, and to gain more insight into the manufacturing process.

Solution

While planning a new drying oven for the new Porsche 911 and Boxster in Stuttgart-Zuffenhausen, Porsche used VPS/DRY within the design phase of the new oven to simulate the paint drying process. VPS/DRY analyzes the temperature distribution, the temperature dwell time and thermal deformations of the car body. By analyzing different variations, the influence of modifications was evaluated, and the design of the oven optimized.

Images: © PORSCHE