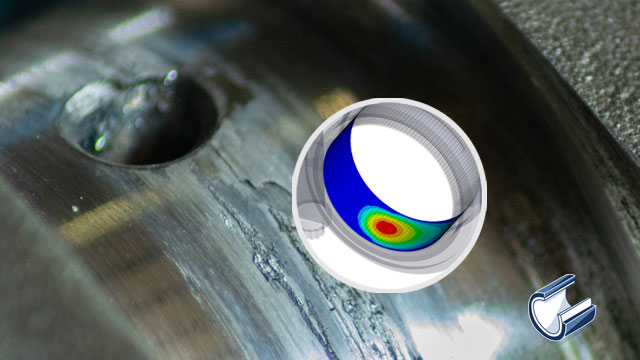

Coupling of hydrodynamics and FEM with the CADFEM Extension Tribo-X inside Ansys for simulation and optimization of journal bearings.

Free Trial VersionTribo-X inside Ansys – efficient simulation of hydrodynamic journal bearings

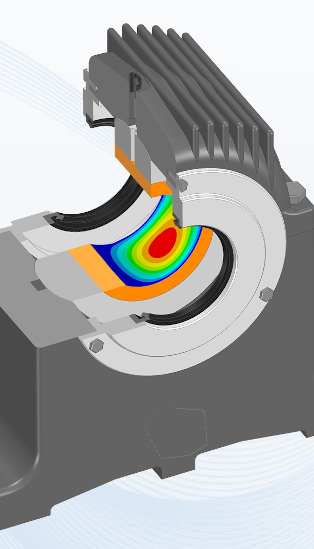

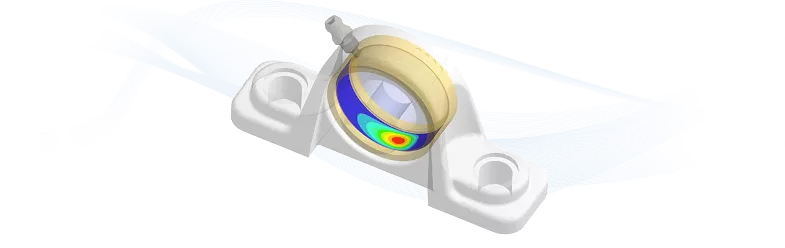

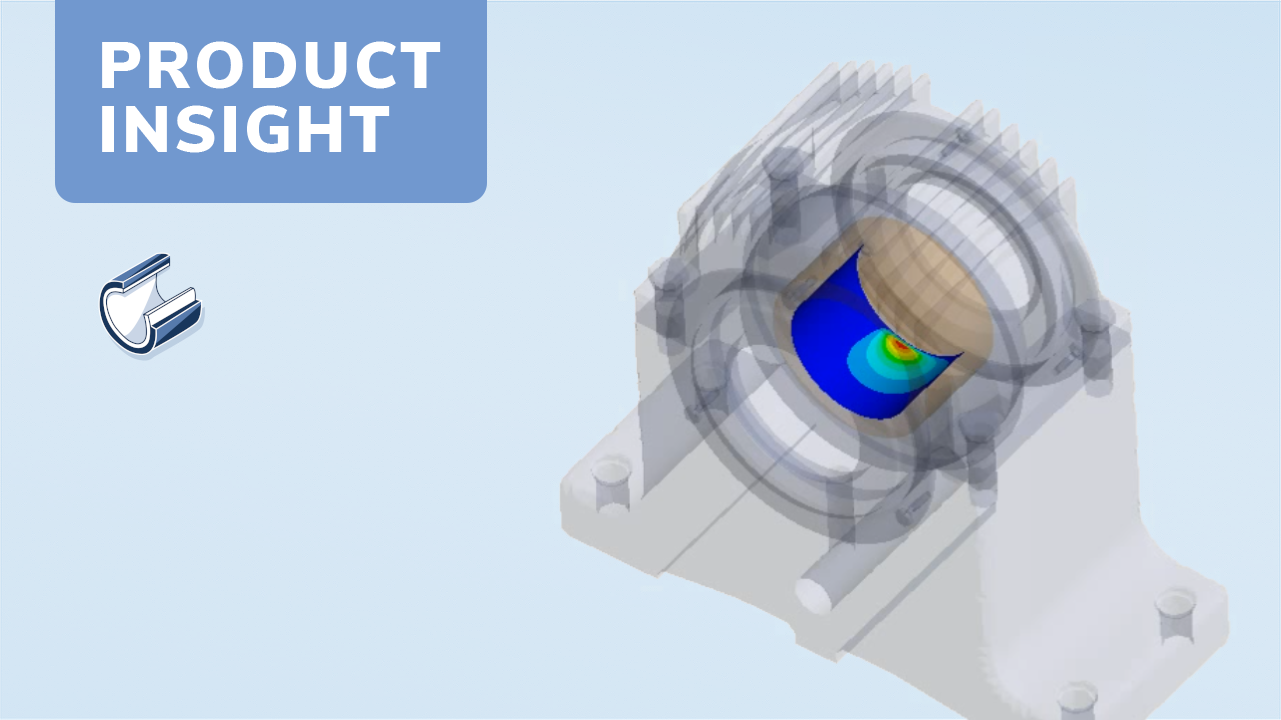

Whether calculating bearing coefficients, bearing deformations, mixed frictions or cavitation – with Tribo-X inside Ansys, the behavior of journal bearings is comprehensively represented in all its complexity. Determining the optimal dimensioning of bearings and rotors takes no time at all with Tribo-X and can be visualized directly on the CAD model within Ansys Mechanical.

Product Description

Calculation of hydrodynamic journal bearings under variable operating conditions

The load capacity and service life of hydrodynamic journal bearings is determined by the optimal dimensioning of shaft, bearing and bearing housing. With Tribo-X inside Ansys, fast parameter studies can be carried out in minutes, or even seconds, in order to adapt the bearing design to the different applications.

Highlights at a glance

- Complete integration of journal bearing with Tribo-X in Ansys Workbench

- Short run times despite the high level of detail

- Taking into account elastic deformations of the bearing (EHD) and their effects on the gap geometry

- Complete representation of the Stribeck curve by taking surface roughnesses into account

- Identification of speed- and load-dependent bearing coefficients for further rotor dynamics analyses

- Simple execution of parameter studies though full parametric workflow

“Linear Rotor Dynamics” add-on module

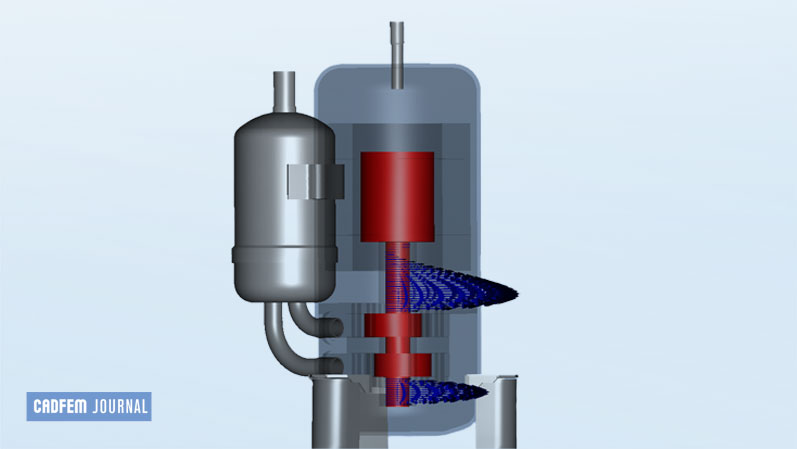

With this module, the speed-dependent stiffness and damping coefficients of a journal bearing can be precisely calculated.

The vibration behavior of journal bearing rotors is influenced by the stiffness and damping properties of the bearing. The bearing properties depend heavily on the speed and operating load and contribute significantly to stable operation of the rotor. With this module, bearing coefficients can be determined for every operating mode and used for the subsequent rotor dynamics analysis in Ansys.

„Thermo“ Add-on module

With this module, the influence of temperature on the operating behavior of the plain bearing can be taken into account

Depending on the operating point, the temperature in the bearing also changes. This leads to locally varying viscosities of the lubricant and significantly influences the bearing behavior of the plain bearing. In addition to dimensioning, the bearing design also plays an important role in dissipating the heat generated. With the module, the temperature influence in the plain bearing is comprehensively taken into account and thus enables optimum thermal management.

“Mixed Friction” add-on module

With this module, a hydrodynamic bearing analysis can be carried out, taking into account the surface roughnesses of bearing and shaft.

There is no such thing as “smooth” surfaces in practice. Instead, hydrodynamic journal bearings go through the mixed friction area during start-up and shut-down processes, high loads and low viscosity. In this transition area, the surface roughness of bearing and shaft play an important role. With this module, the roughness is fully taken into account, which allows complete calculation of the Stribeck curve.

Reliable and durable

CADFEM is the right partner for you.

For more than 35 years we have been designing and supporting the introduction of simulation with our customers - from engineering offices to large corporations. We use our diverse experience and know-how to make your entry into simulation a success. Acquisition of the software is only the beginning. As your partner, we accompany you step by step - with intensive technical support and strategic consulting that ensures your long-term goals.

Please contact us for more information.

Training and Webinars for Tribo-X inside Ansys

Suitable for simulation engineers and designers who want to gain an initial insight into the design and scope of the CADFEM extension Tribo-X inside Ansys for calculating and simulating hydrodynamic bearings.

Our development partner

The right solutions for your simulation projects

Simulation is everywhere and affects every industry. Since simulation requires more than software, CADFEM offers everything you need for successful simulation from a single source: software and IT solutions, consulting, support, engineering and knowledge sharing – always on the cutting edge.