Multiphysical simulation in battery development

KTM – The Magic of e-Ride

KTM is one of the largest motorcycle manufacturers in Europe. Its mission is to continue pushing the boundaries of performance and innovation, and to set new standards. Simulation with Ansys and CADFEM support plays a major role in all phases of development and creates new challenges in the young segment of e-motorcycles.

Simulation is part of the DNA of KTM

Many influencing factors come together in the design process of a motorcycle. KTM’s research and development is therefore very simulation-driven. This is guaranteed by an interdisciplinary simulation team with expertise in a wide range of fields like structural mechanics and composites, as well as aero- and thermodynamics. This broad spectrum of expertise makes KTM independent and allows it to tackle new challenges with high efficiency.

Due to new challenges and technical requirements, the simulation department at KTM is constantly growing and has access to all Ansys software tools thanks to an Ansys Corporate License. In addition, the company’s own high-performance computing resources, such as an HPC cluster, offer all technological prerequisites for highly professional virtual product development according to current standards.

Last but not least, the long partnership with CADFEM is also a factor for the successful implementation and use of simulation. It goes far beyond the procurement of software and hardware. In addition to training and further education, it also includes hotline support, frequent professional exchange, and support with particularly tricky simulation tasks or when breaking new ground.

About KTM

With a great deal of dedication and the utmost focus, KTM builds motorcycles that dominate their respective classes. KTM believes that the impressive facts and figures the company can boast about are the result of hard work. This is a testament to its success - not just the reason for doing business. www.KTM.com

KTM’s mission is to make a splash in the field of e-mobility.

More than a trend: e-mobility on 2 wheels

Demand for electrically driven motorcycles is on the rise. KTM’s mission is to make a splash in the field of e-mobility and to continue growing This includes achieving top performance and offering customers the best possible technical and emotional experience - without the emissions and noise of a combustion engine. These are decisive factors for a high level of acceptance, in both urban and off-road environments.

When starting out in the field of e-mobility, KTM was able to build on its own expertise in motorcycle development, because it knows what matters when it comes to chassis and suspension construction, or generally in the design of efficient development processes. The task now was to find the best way to deal with the newly added challenges, which are essentially the design and development of the electric motor and traction battery.

Inspired by the world record

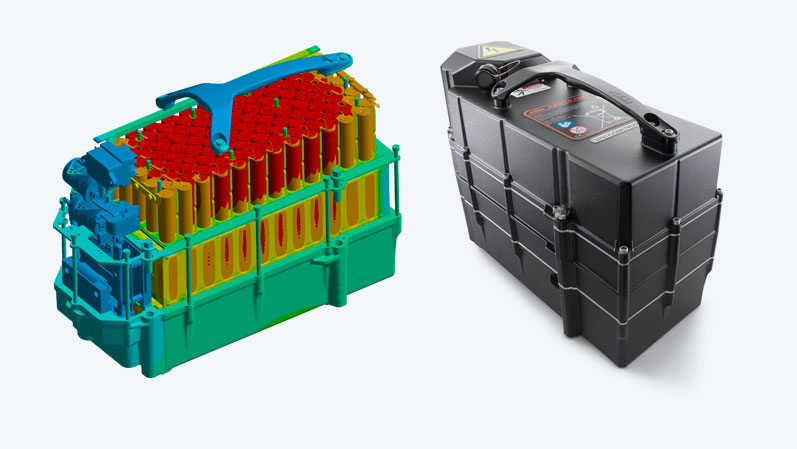

When it comes to batteries, thermal management is the central issue. The aim of the project presented here was to implement a simulation workflow (i.e., one that is scalable to different models) that enables virtual design, validation, and optimization of the traction battery.

The team was inspired by the Volkswagen/Ansys collaboration at the 2018 Pike’s Peak Hill climb, which resulted in a record-breaking performance of the Volkswagen ID.R using an Ansys-based multi-physics simulation model for their battery pack. The technical background of this performance was presented at the CADFEM Ansys Simulation Conference 2019 .

Racing fans were amazed when the Volkswagen ID. R broke the 8-minute barrier at the 2018 Pike’s Peak International Hill Climb. It currently holds the overall record for the course. Not bad for a vehicle with a battery pack. Ansys was instrumental in the development.

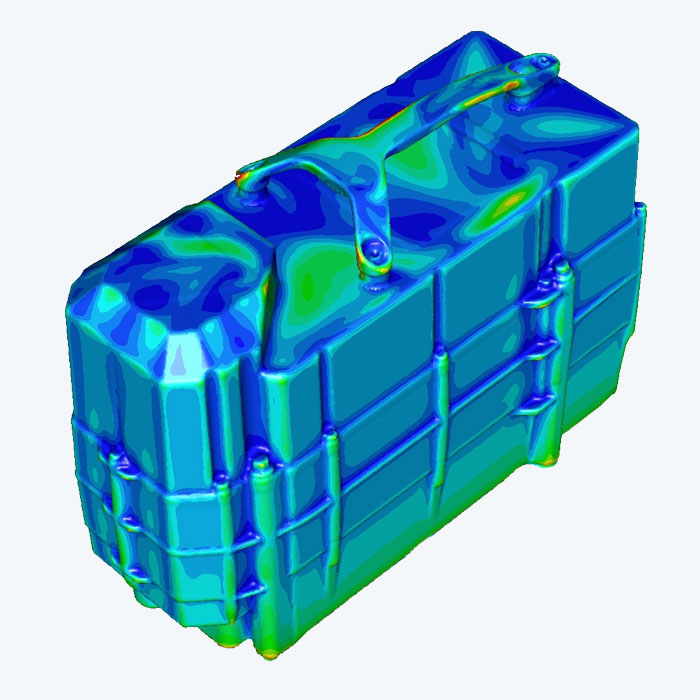

Traction battery: Can only be represented as a coupled system

The KTM simulation team’s adept handling of Ansys simulation tools facilitated the first steps. However, Ansys tools such as Workbench, Mechanical, and Fluent, while previously used for a wide range of simulation tasks, were mostly used separately.

In the case of the traction battery, such singular approaches were not sufficient. A coupled simulation system of different models was required because it was the only way to realistically represent the important interactions between real-world physical phenomena.

Nevertheless, separate simulations of the temperature fields or the flow behavior are sufficient for the initial stages of pre-development, i.e., initial concept evaluations, rough estimates, and relative comparisons of various designs. However, in order to achieve the major goals in optimal battery design, such as

- avoiding of thermal hotspots,

- optimizing temperature distribution or

- determining the best constellation for efficient fast charging,

a much more complex (namely “multi-physical”) simulation model is required. It must be able to predict temperatures in the battery as a whole under realistic usage conditions.

System simulation with Ansys Twin Builder

With the support of multiphysics experts from CADFEM, the KTM team successfully developed a simulation workflow within Ansys Tools. Ansys Twin Builder was chosen as the platform for the system simulation.

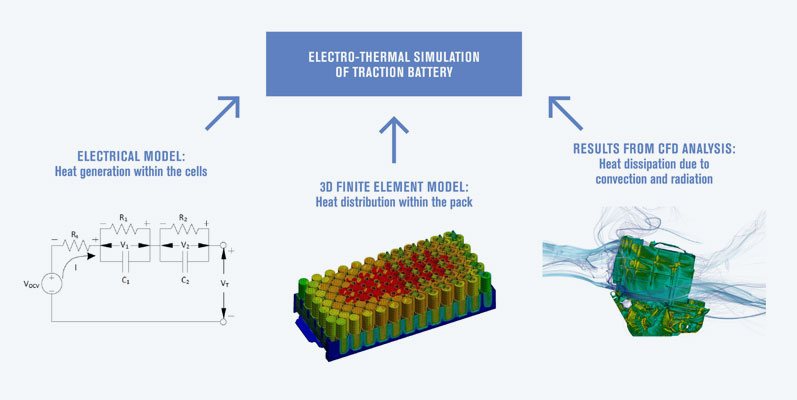

Simply put, the overall multi-physics model for the battery pack consists of three submodules, which are coupled at the system level and exchange input and output data during computation:

- An electrical lumped model is used for the model generation in each cell as a function of cell temperature and state of charge.

- The resulting values are fed into a compact thermal model (derived from 3D FEM models) that calculates the temperature distribution within the battery.

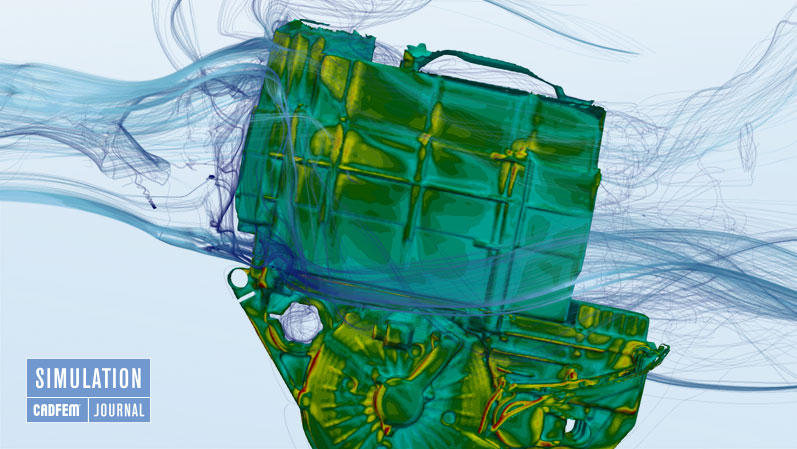

- The third sub-module is based on the results of a CFD analysis to determine thermal dissipation due to convection and radiation from the battery housing.

The thermal finite element model was initially created and meshed in Ansys Mechanical. However, the computation time for a transient simulation is usually high due to the large number of degrees of freedom and the long transient loads. To significantly reduce simulation time and thus enable coupling with other models at the system level, the team applied the CADFEM Ansys extension “Model Reduction inside Ansys”.

Detailing high-dimensional FEM models is important for accurate and efficient dynamics and systems simulations. Model Reduction inside Ansys reduces the number of degrees of freedom (DoF) to the point where multiphysics system simulations are possible. www.cadfem.net/modelreduction

Reduced model for drastically accelerated computation

This special tool allows the extraction of a reduced order model (ROM) from Ansys Mechanical with significantly fewer degrees of freedom, drastically speeding up the solution with a negligible loss of accuracy. The battery pack ROM was verified using transient simulation of a full 3D model to keep track of accuracy and to determine the optimal parameter settings for model order reduction within the CADFEM extension.

The electrical model is based on an Equivalent Circuit Model (ECM), which can be used to compute the electrical performance and losses of the lithium-ion cells as a function of state of charge and temperature. To use the ECM, its parameters must first be identified for the requested cell. This is usually done by running a series of experimental tests with the battery cell at a temperature range within the desired design and measure the voltage response.

The required parameters for the circuit components can then be extracted from the test data and make it possible to model the instantaneous and dynamic behavior of the cell.

KTM and CADFEM

KTM and CADFEM have had a very long partnership.

Cooperation and the use of Ansys simulations was established in the R&D team over 10 years ago. In addition to the procurement of software and hardware, KTM also relies on CADFEM for training and support, which includes frequent professional exchange between KTM and CADFEM simulation experts as well as joint projects.

Well-founded decision: Battery Wizard Toolkit

KTM Research and Development has the required hardware and testing facilities to perform the necessary cell tests in-house. This made it possible to create a cell database of all options that are considered for a given project. The test data measured during the pulse-discharges at various temperatures is then imported into the Battery Wizard-toolkit in Ansys Twin Builder, which automatically generates the required lookup tables of the ECM for each cell.

This later provides the ability to quickly change between different cells in the system model and supports the design team in decision making. In addition, once the ECM tables are created for a single cell, the wizard can configure an electrical model for the battery module by connecting the cell ECMs in parallel and in series according to the pack specification. This ECM module is later implemented and coupled in the final Twin Builder system simulation. The underlying Python scripting capabilities in Twin Builder provided an efficient method to couple the models to the appropriate outputs.

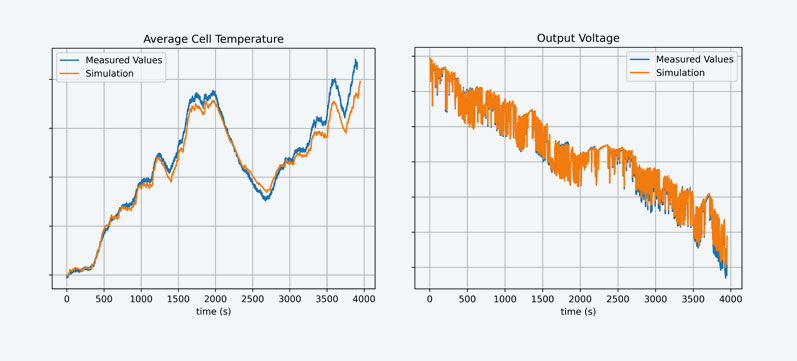

Furthermore, the coupled model, which combines the benefits of separate simulations, was iteratively validated. This process included matching with both constant current and dynamic discharge measurements. The various steps ranged from validations of the output voltage of the ECM for a single cell to the predicted voltage and temperature of the entire battery. For a single cell, the predicted output voltage showed an error of less than 20 mV. For the overall battery pack model, a temperature deviation of less than 2°C was achieved for certain drive cycles compared to the measured cell temperatures.

Even for the most complex and largest models, the computation of hour-long drive cycles is solved near real-time.

Reliable prediction of various scenarios

Once fully implemented in Twin Builder, the electro-thermal model of the battery pack could simulate real-world drive cycles and predict outputs data such as peak temperatures, temperature distribution, and heat transfer. Even for the most complex and largest models, the computation of hour-long drive cycles is solved near real-time, while simpler models are completed within minutes. With the help of the virtual battery pack, potential problems and design issues could be identified and eliminated early on.

The model was used to compute load cases specified for concept evaluation such as

- drive cycles from real-world measurements

- standardized specifications like the WMTC (World Motorcycle Test Cycle)

- CC-CV charging

Due to the accuracy of the predicted absolute values, the model further facilitates the decision-making process regarding important design questions. One of these being the air cooling of the battery pack, where the virtual model is used to evaluate the trade-offs between different concepts for the geometry of the battery pack housing as well as the design of the motorcycle fairing.

This allowed optimization of the overall cooling concept to achieve the best efficiency. Nevertheless, physical prototypes of the battery pack were built at key milestones for validation testing and to meet safety requirements. The existence of a high-fidelity virtual battery model allowed the KTM development team to significantly reduce the time and costs of physical testing of the battery packs in the design process.

KTM FORSCHUNGS UND

ENTWICKLUNGS GMBH

David Singer

www.ktm.com

Authors: David Singer (KTM F&E), Lucas Kostetzer (CADFEM Germany GmbH)

Images: © KTM F&E

Published: June 2022

Contact CADFEM