with Digital Engineering using Simulation

Responding to rising material and energy prices

One of the biggest challenges facing companies is the efficient use of materials and energy. Increased volatility in commodities markets is leading to a sharp rise in material and energy prices along with supply disruptions. This has a direct impact on profitability. The aim is to optimize material and energy efficiency throughout the product value chain.

Concrete solutions and benefits

Here are the new challenges facing industrial companies to ensure their sustainability:

- Rising costs of raw materials and energy: how to be sober without reducing product quality and production rates?

- Introduction of carbon taxes progressively: how to anticipate these costs and adapt production methods?

- Increasingly stringent environmental requirements: how to meet the tightening of standards, customer demand and the objective of energy neutrality planned for 2050?

In all cases, companies prefer to anticipate this inevitable transition, rather than undergo it and become uncompetitive.

Which actors in the company could facilitate this transition?

R&D designers and engineers play a key role in making this transition a success. Indeed, the decisions taken during the design phase of products determine the quantities of materials and energy required for their production and use, and more generally their environmental impact during their life cycle.

How can the environmental performance of products be improved?

First of all, by measuring it! Measuring means understanding and evaluating in order to better decide and prioritise. To do this, there is a simple methodology: life cycle analysis. This analysis enables us to estimate the CO2 emissions of a product throughout all the phases of its life: extraction, production, transport, use and end of life. Lightweight life cycle assessments can be quickly and easily carried out during the design phase before moving on to the full ISO 14040 analysis.

Two approaches to improve environmental performance emerge:

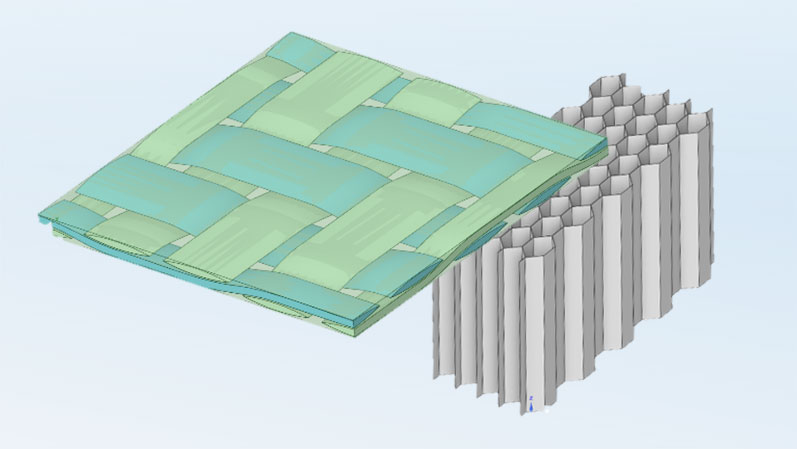

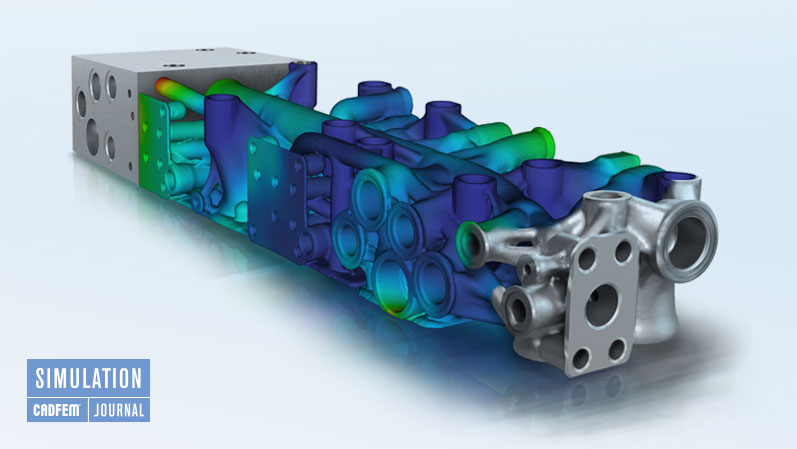

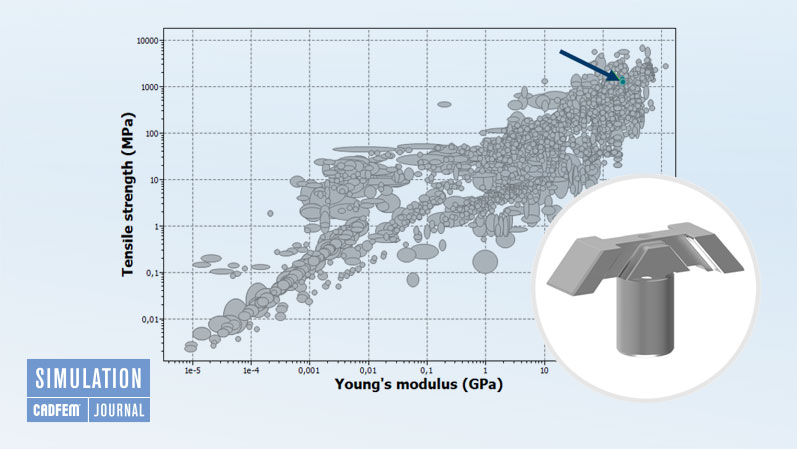

- Look for more sustainable alternatives: choose more sustainable materials, manufacturing processes and transport modes

- Optimise the following technical points:

- Minimising the mass and volume of materials, which have a direct impact on extraction and transport emissions.

- Minimise production effort (less energy consumed, fewer prototypes, etc.)

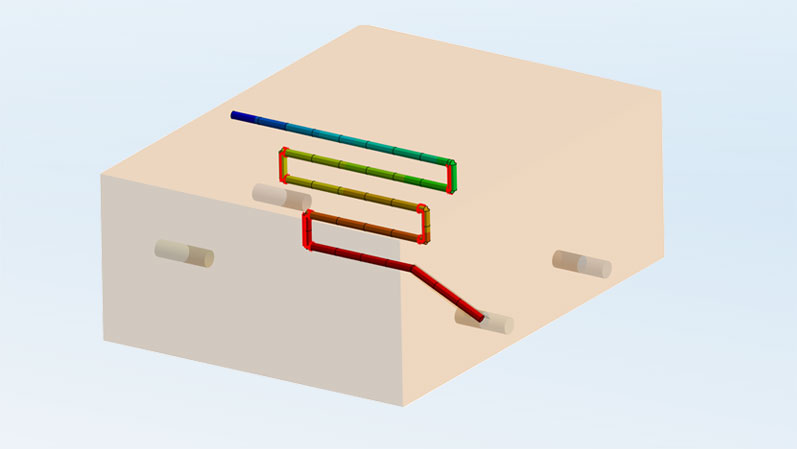

- Maximise the energy efficiency of products

- Maximise the life span of products

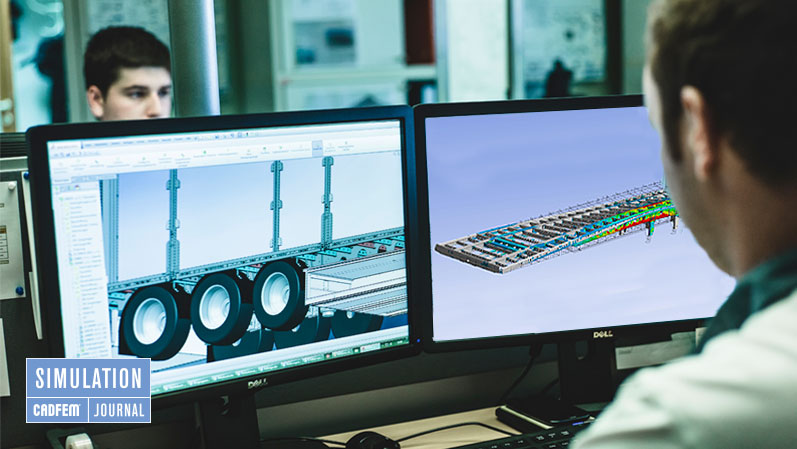

Numerical simulation tools are particularly suitable for this purpose. They allow the behaviour of the product during the different phases of use to be evaluated and quantified, and thus the geometry to be optimised while respecting the specifications.

What are the direct financial benefits?

Reducing the amount of material and energy required results in cost savings. The many industrial examples presented in the webinars show very short paybacks.

Increasing energy efficiency and product life also brings a competitive advantage to the customer. In addition, environmental performance stems from the search for savings and gives competitive advantages: it responds to the growing customer demand for truly sustainable products. To learn more, we invite you to discover in the following webinars the solutions and examples, already implemented by our engineers, at some of our customers.

Practice-oriented webinars from experts

When it comes to reducing material and energy consumption in the long term, what do practical solutions look like? In our compact webinars, our experts will show you how digital engineering using simulation can help you stay ahead in terms of material and energy efficiency. Each of the webinars will focus on a different topic and will conclude with an open Q&A.

Practical use cases for more resource efficiency

What approaches are there to use material and energy more efficiently? Our CADFEM Best Practices provide you with practical use cases that show you how to achieve more resource efficiency with digital engineering using simulation.