Process simulation of labeling PET bottles

Sector: Machinery and plant engineeringSpecialist field: Structural mechanicsAnalysis of the deformation behavior of empty, filled and closed PET bottles in a high-speed labeling machine with Ansys LS-DYNA.

Summary

Task

In the high-performance areas of labeling technology, undesirable deformations occur in PET bottles due to the lower modulus of elasticity and the much thinner walls compared to glass bottles. For a specific machine speed, information about deformation behavior can be helpful as early as the machine planning stage.

Solution

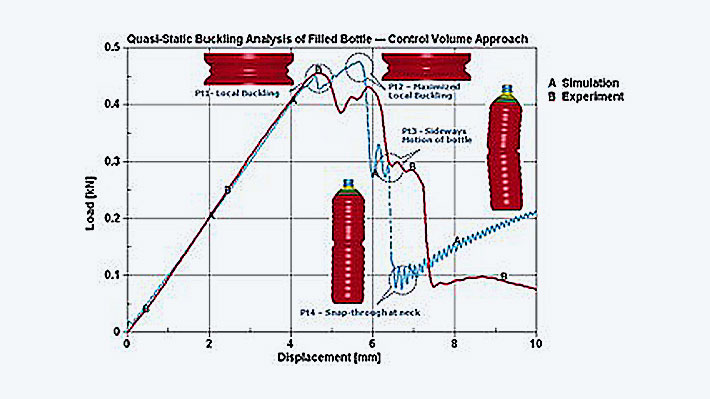

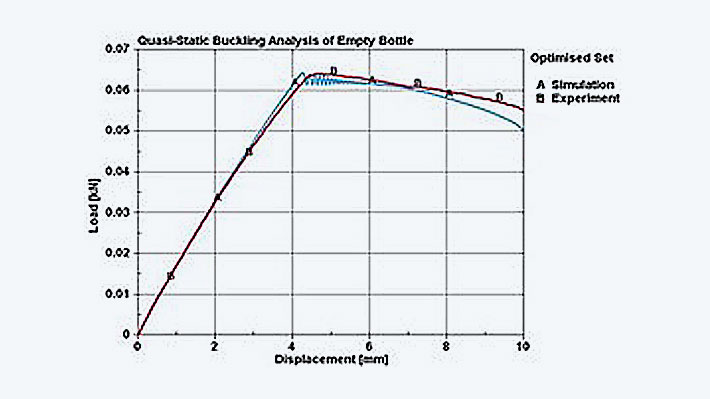

The quasi-static buckling analysis of the empty bottle with the optimized parameters (material, geometry and finite elements) showed a close match of the pre- and post-buckling behavior with the test data. A similar match of the initial slope and buckling load for a filled bottle was obtained by properly accounting for the presence of water and air as well as their physical properties (compressibility, inertia and hydrostatic pressure) in the filled bottle.

Customer benefits

It was determined that the lateral deformations of the bottle are within the permissible limits. Thus, a label can be applied in the correct position. In addition, precise information was obtained on the deformation behavior of a PET bottle in a high-speed labeling machine.

Project Details

Task

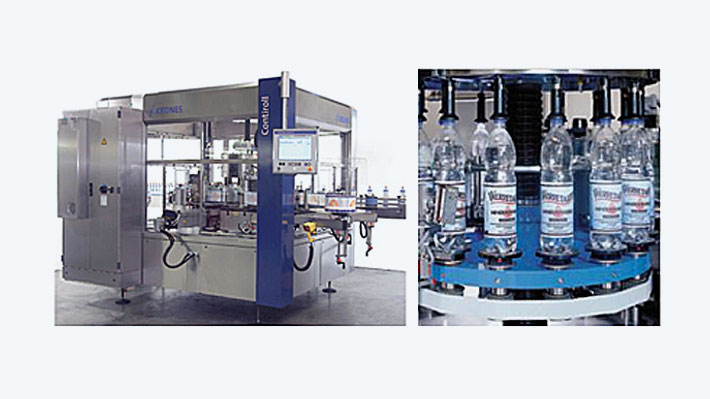

With an output of 67,500 containers per hour, the KRONES Contiroll HS wrap-around labeler is the trendsetter in labeling technology. In these high-performance areas of labeling technology, however, undesirable deformations occur in PET bottles due to their lower modulus of elasticity and much thinner walls compared to glass bottles. For a specific machine speed, information about deformation behavior can be helpful as early as the machine planning stage. In order to determine this information, three analyses were carried out.

- Top-load simulation and verification of the empty PET bottle: to obtain a reliable model of the empty PET bottle

- Top-load simulation and verification of the filled PET bottle: to obtain a reliable model of the filled PET bottle

- Process simulation of the filled PET bottle in the high-speed labeling machine: to verify the deformation behavior of the PET bottle

Customer Benefit

It was determined that the lateral deformations of the bottle are within the permissible limits. Thus, a label can be applied in the correct position. In addition, precise information was obtained on the deformation behavior of a PET bottle in a high-speed labeling machine.

Solution

The quasi-static buckling analysis of the empty bottle with the optimized parameters (material, geometry and finite elements) showed a close match of the pre- and post-buckling behavior with the test data. A similar match of the initial slope and buckling load for a filled bottle was obtained by properly accounting for the presence of water and air as well as their physical properties (compressibility, inertia and hydrostatic pressure) in the filled bottle.

Since the bottle, along with the liquid, undergoes two types of rotation in the labeling machine in 803 ms (in relation to the table and in relation to itself), the inertial forces (centrifugal and Coriolis force) were included in the calculation with proper machine kinematics. The water was idealized using SPH particles (Smoothed Particle Hydrodynamics) to accurately capture the inertial effects of the water.

Images: © KRONES AG