Simulation-supported digital twins of products, plants or processes ensure their availability and minimize the effort required for maintenance and servicing.

Arrange a consultationDigital twins: individual, precise, predictive

From real-time monitoring of a product or plant during operation to the virtual image of a process and detailed digitized prototypes: Digital twins create great added value - the CADFEM team advises, accompanies and supports you in your project!

CADFEM – Your strong partner for the implementation of your Digital Twin

The digital twin - Exclusive video insights

These short videos will give you a compact overview of what a digital twin is, how it has been implemented

in projects of different application areas and how we proceed when implementing a digital twin.

Operators of plants or equipment benefit from digital twins by an improved availability. The exact knowledge about the asset condition prevents downtime and the loss of production. In addition, digital twins provide a view into the future and how the mode of operation can be optimized e. g. by balancing energy costs, runtime, maintenance demand, asset performance and product quality.

Instead of a pure hardware business, digital twins enable new services like predictive maintenance, recommendations-as-a-service, spare-parts-as-a-service or performance-as-a-service. The result of such additional, operation oriented services is a long term customer relationship and a better feedback about the real usage and the real need for future product capabilities.

Implementation of a digital twin at Verbund Hydro Power

Collection of different Twin Applications

Implementing a Digital Twin

Best Practice: How Technology Leaders benefit from Digital Twins

Recording from October 6th, 2020

The best solution for you

CADFEM competently accompanies you on the way to a customized Digital Twin solution.

- Benefit from CADFEM and ITficient know-how

- Personal contact persons with profound practical knowledge in the areas of structural mechanics, computational fluid dynamics, system simulation, data management, programming and cloud solutions.

- Experience from numerous implementation and expansion projects for customers of all sizes and with a wide variety of requirement profiles and specifications.

What can we do for you? We look forward to speaking with you.

Karthik Chittepu

Recommendation: An intensive workshop with CADFEM and ITficient

A moderated intensive workshop with in-depth analysis of requirements, goals and prerequisites has proven to be the basis for a successful Digital Twin project. Together we specify:

Stakeholders: Who in the company is affected?

Perspectives: What are the challenges, what are the added values?

Personas: Who are the future active users?

Prioritization: Which use case is suitable to start with?

Technical analysis: Which models, sensor data, IT infrastructures are available?

Best-practices

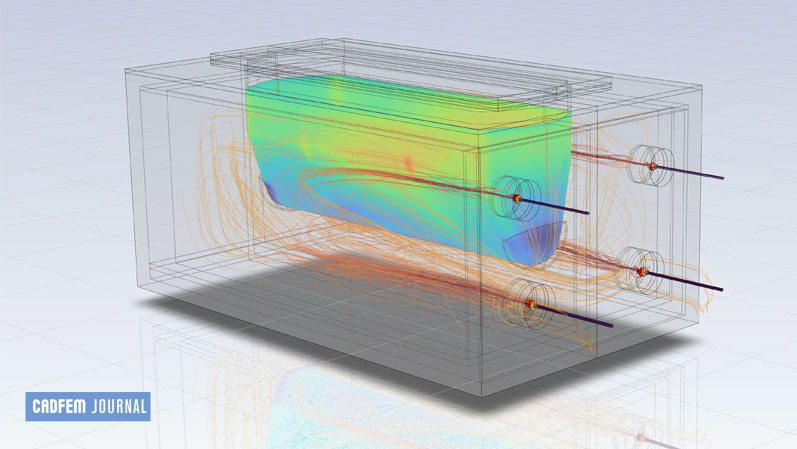

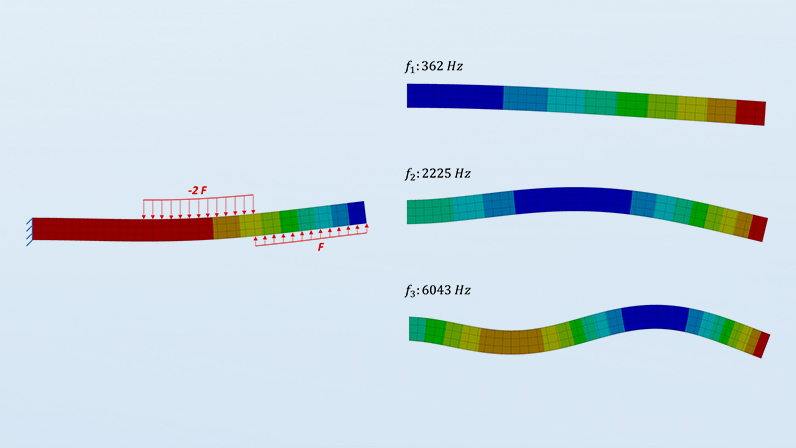

Real-time sensor data, data from the control system or even information about maintenance cycles can be used to associate a physical product with a corresponding numerical simulation model. This digital twin not only allows you to carry out precise condition monitoring during operation but also lets you predict remaining service life.

Condition Monitoring for GE Wind Turbines

GE Wind will demonstrate how virtual sensors for the drive motors of its wind turbine control room help to detect potential failures in advance. This allows the condition to be assessed in real time and remotely without physical inspectors on site.

Watch this video to learn how ANSYS and GE engineers built simulation-based digital twins to monitor the maximum temperature and torque of the turbine’s motor coils to save time and money in the operation of offshore wind turbines.

Training on the topics of Digital twins

All CADFEM training are characterized by a strong practical focus, sustained learning outcomes and a pleasant learning atmosphere.

More on the topic

Added value through digital services

CADFEM supports you developing business models that enable long-term customer loyalty and new services such as "Maintenance as a Service" or "Recommendation as a Service" with Predictive Maintenance.

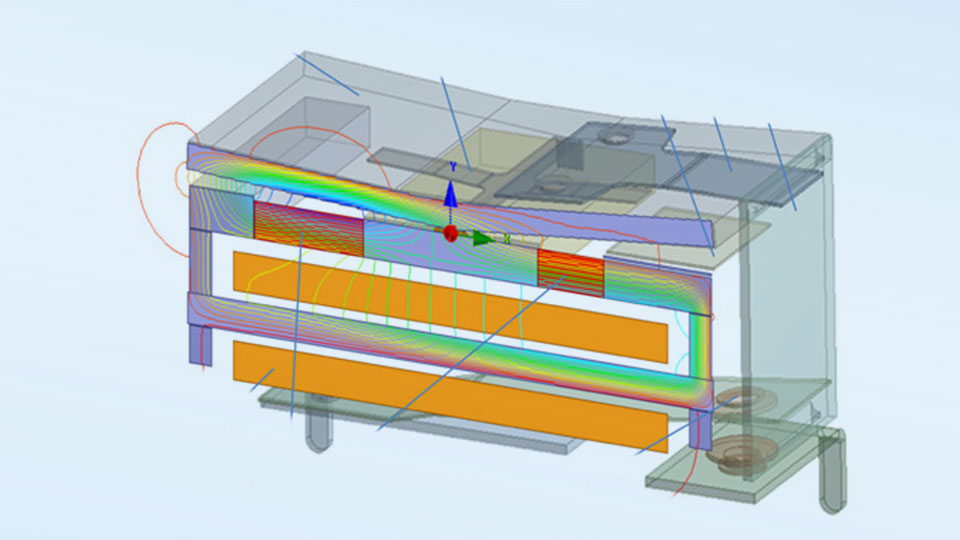

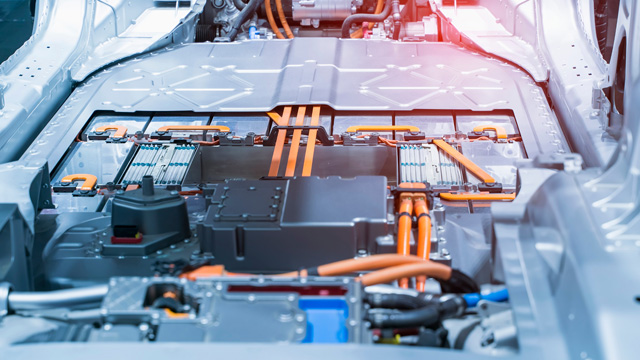

Condition Monitoring in Battery Packs

A manufacturer of traction batteries uses virtual sensors to detect the state-of-charge (SoC) and state-of-health (SoH). They become the basis for usage-based services for OEMs, fleet operators and drivers.

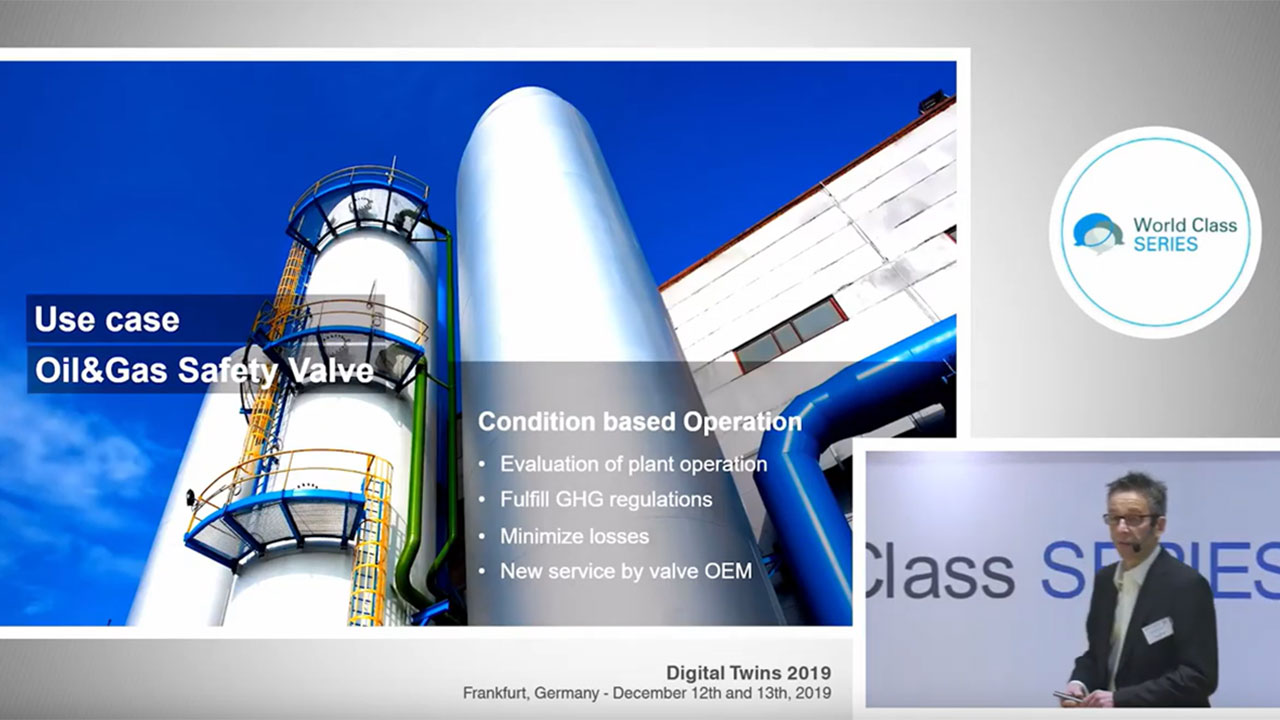

Virtual Sensors-as-a-Service of a valve manufacturer

ITficient and CADFEM will present the new service of a valve manufacturer for oil & gas conveyors to reduce greenhouse gas emissions and increase plant efficiency.

Condition monitoring in process technology

At the Hannover Fair 2019, SAP SE and CADFEM Group will present a digital twin for process engineering to evaluate the failure of critical components (e.g. seals) and to adjust operating profiles.

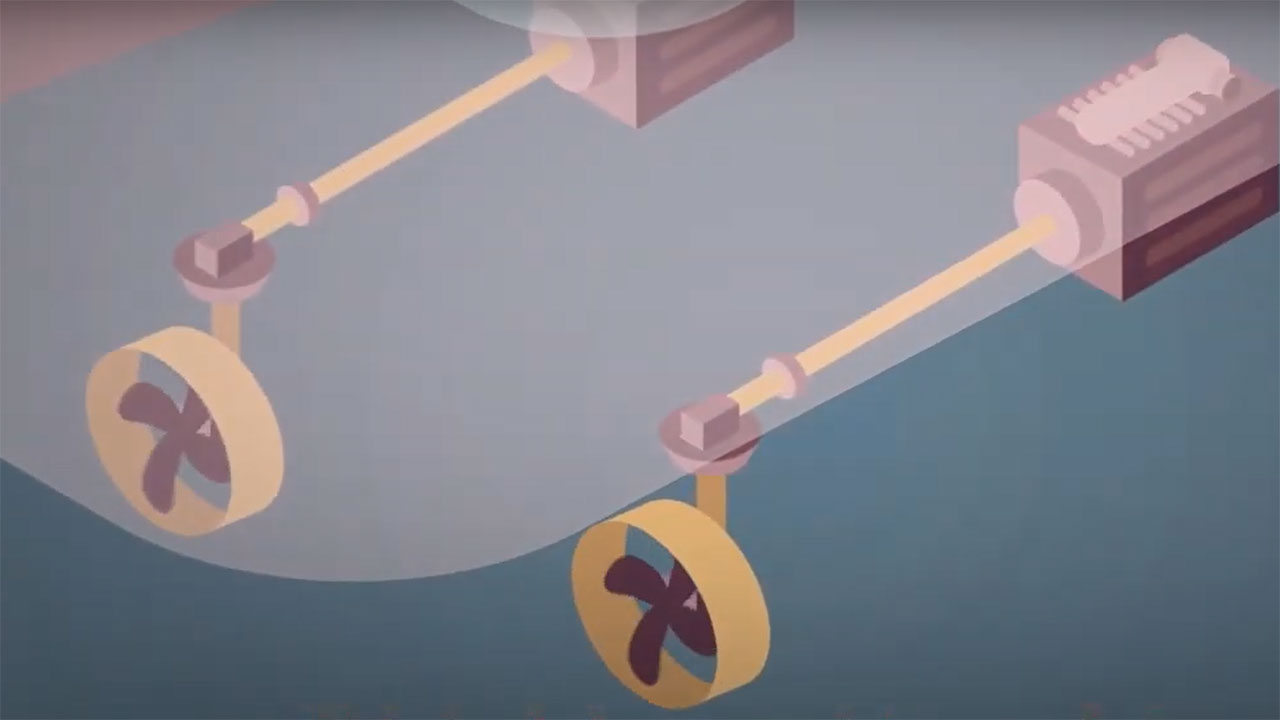

Differentiation through service for Kongsberg Marine Propulsion

Kongsberg offers online monitoring with virtual sensors for its ship propulsion systems in order to analyze their condition and the effects of adjusted power demand, with regard to maintenance requirements and availability.

The right solutions for your simulation projects

Simulation is everywhere and affects every industry. Since simulation requires more than software, CADFEM offers everything you need for successful simulation from a single source: software and IT solutions, consulting, support, engineering and knowledge sharing – always on the cutting edge.