How Bosch uses simulation to develop remarkably quiet heat pumps

Heating without noise

Heat pumps are an essential component of energy transition in buildings. For the Bosch Home Comfort Group, their development and production is a high priority. In addition to the performance and energy efficiency of the heat pumps, the noise level plays an important role in the purchase decision and the satisfaction of the end customers.

In order to integrate this topic into the development process in a formative way, a Bosch team in coopaeration with Tribo Technologies, CADFEM and Ansys has developed a simulation solution in cooperation with CADFEM and Ansys.

The Bosch Home Comfort Group offers innovative and sustainable solutions for heat, climate, and comfort in buildings and is making a significant contribution to energy transformation. In line with our mission statement "Make. Home. Comfort. Green.", we are leading the way with a technological and digital pioneering spirit, developing technology for life: inspiring products and services that sustainably improve living comfort and thus people's quality of life. The focus is on heat pumps, because electrification is the most important step in achieving climate goals. However, noise emissions should be kept to a minimum in order to ensure a pleasant quality of life for users and their environment.

The Bosch Home Comfort Group is a leading European supplier of smart, sustainable, and energy-efficient solutions for heating, cooling, comfort and process heating. In fiscal year 2022, the company generated sales of 4.5 billion euros with around 14,400 employees. www.bosch-homecomfortgroup.com

Less compressor vibration with reduced measurement effort

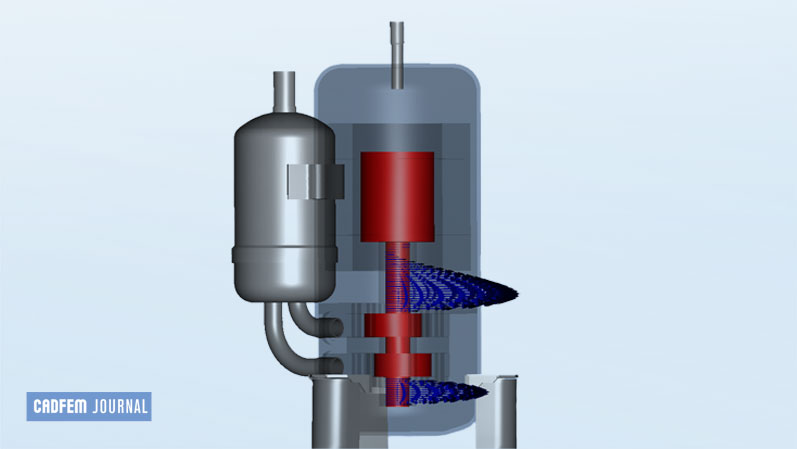

It was clear to everyone involved that compressor vibrations play a major role in noise generation inside heat pumps. However, in experimental analyses, it's not always possible to see in detail what's going on inside the compressor. This should be accomplished by using multi-body simulations (MBS) with Ansys Motion.

There were several objectives. One was to gain a deeper and broader understanding of compressor excitation in order to be able to more accurately predict noise levels when using heat pumps. Another goal was to reduce the measurement effort, which was not insignificant. An additional challenge was that interactions in the compressor can be difficult or even impossible to measure.

“Since Ansys Mechanical is already used for FE simulation in our department, it made sense to use Ansys Motion for multi-body simulation,” explains Anja Thielecke, who is doing her PhD on acoustics in the Engineering Application System area at Bosch Home Comfort Group. “These calculations can be controlled using Ansys Workbench just like Ansys Mechanical. As a result, MBS analyses can be performed with little effort in addition to FE simulations.”

Simulation shows plain bearings “under the microscope”

Plain bearings play a decisive role in the vibration behavior of compressors. A simulation solution was therefore needed to calculate these bearings in detail. Tribo-X inside Ansys, a software developed by CADFEM together with Tribo Technologies for coupling hydrodynamics and FEM, offers this possibility in Ansys Mechanical. The add-in comprehensively models the behavior of shafts with plain bearings in all its complexity, for example to calculate plain bearing coefficients, bearing deformations, mixed friction, or cavitation.

Tribo-X inside Ansys at a glance

Bearing damage can be predicted and avoided with correct dimensioning of the plain bearing. Every µm is important here. In this video, you will learn how deviations in shape and position (e.g. shaft misalignment, mounting errors) affect the lubrication gap height and wear in the plain bearing. You will also learn how these deviations can be avoided by design.

Ansys Motion + Tribo-X = accurate vibration prediction

So that Bosch could also use the Tribo-X software in a multi-body simulation, Tribo Technologies and Ansys jointly implemented its integration in Ansys Motion. This brought further advantages to the development engineers who analyze and optimize the acoustic behavior of Bosch heat pumps.

This improved the qualitative predictability of vibration excitation as well as the identification of crucial factors for the accuracy of vibration prediction. Based on parameter analyses, Bosch engineers were able to qualitatively predict the behavior of the compressors for the various operating points in sequence.

Anja Thielecke, PhD candidate, Bosch Home Comfort GroupWith our calculations, we were able to show the influence of the plain bearings on noise development.

A better understanding of the interactions

“With our calculations, we were able to show the influence of the plain bearings on noise development,” reports Anja Thielecke. “By qualitatively modeling the frequency spectrum, we were able to understand the effects of our acoustic optimizations on the compressor. Moreover, the complementary use of measurement and simulation meant that a method for reducing vibrations could be tested using measurements. At the same time, we used simulations to check our understanding of the relevant interactions. Here we repeatedly benefited from the comprehensive know-how of the CADFEM specialists who accompanied us throughout the project.”

Overall, the use of simulation is seen to have a high potential benefit. The vibration of the compressor could be reduced by up to 20 dB, which corresponds to a factor of 10, for individual orders. This would result in a significant noise reduction in the heat pump.

Positively influence product properties at an early stage

Another important advantage is that simulations can be used to evaluate acoustic measures early in the development process (shift left). This not only saves costs for changes that are recognized late but are absolutely necessary and for time-consuming measurements, but also improves the expected product properties at an early stage. .

Noise is one of the most strongly perceived environmental impacts for people. The added value for Bosch customers and for their environment is thus reflected in the pleasant-sounding and barely perceptible heat pumps.

Bosch Home Comfort Group

Author: Gerhard Friederici

(CADFEM Germany GmbH)

Cover images:

Right: © Bosch Home Comfort Group

Left: © Bosch Home Comfort Group

Published: September, 2023

Contact CADFEM