End-to-end simulation workflow for optomechanics

Quicker to high-precision optoelectronic sensors

The name ifm electronic stands for automation and digitalization “made in Germany”. One of the core areas is optical sensors, which must be able to record and transmit signals with high precision. This can only be achieved using several simulations, the combination of which was once a very time-consuming process: until an optomechanical workflow, together with ifm, was developed in Ansys.

Contactless switches, light barriers, object detection, identification systems: Photoelectric sensors from ifm, headquartered in Essen and with technology centers in the Lake Constance region, are omnipresent.

With digitalization and the transformation to Industry 4.0, the demand for sensor solutions has increased dramatically. High-performance, extremely reliable, and often highly specific products are in demand. The range of applications and areas of use are enormous.

Without the use of simulation technology, the development of optical sensors cannot be accomplished today. Early on, ifm established a competence team for simulation and calculation at the Center for Technology and Process Engineering in Tettnang. It was initiated and is still headed by Bernhard Schneider, who, at the SPS-IPC-Drives trade fair in 2012, discovered Ansys as the right software and CADFEM as the right partner for the sustainable use of simulation at ifm.

Bernhard Schneider, Head of Technology and Process Engineering, ifm electronic gmbhWe have already worked on several projects together with CADFEM and have had consistently positive experiences in terms of project support and cooperation.

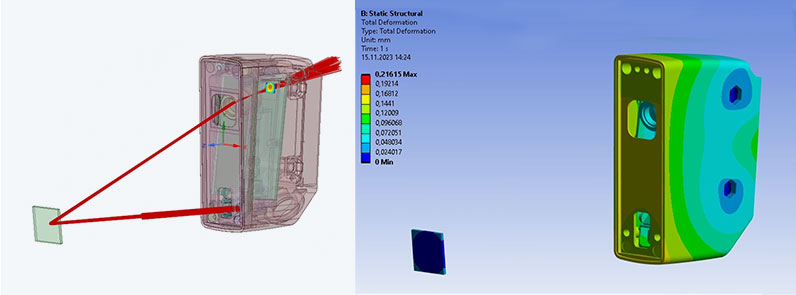

Structural Mechanical Simulations

The starting point - even if this is not necessarily expected in the fields of automation and sensor technology - was structural mechanical calculations with Ansys Mechanical. The strength of components is an elementary quality feature that must be ensured if the component is exposed to thermal effects or vibrations. Analyses of this kind are time-consuming, error-prone, and incomplete, especially in early development phases on the test bench. The simulations carried out by Bernhard Schneider and his team have not only made the test cycles and development loops considerably shorter and more cost-effective, but have also provided many additional insights, including for further developments.

Optical Simulations

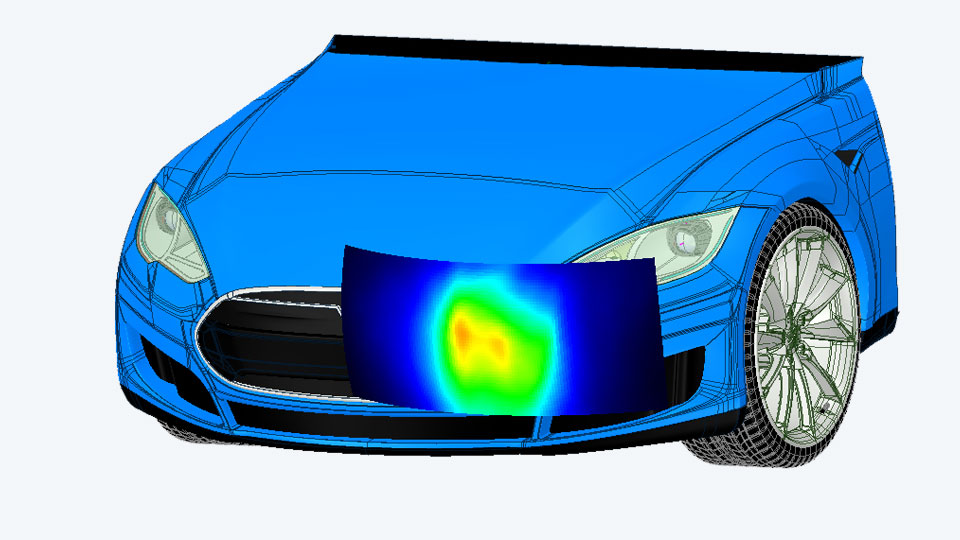

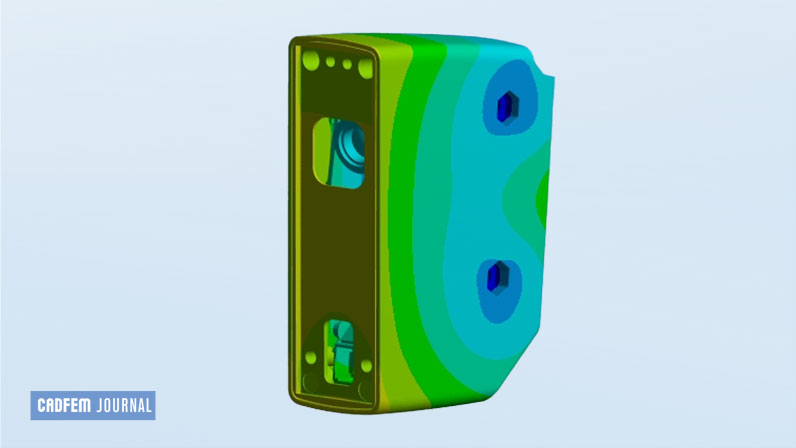

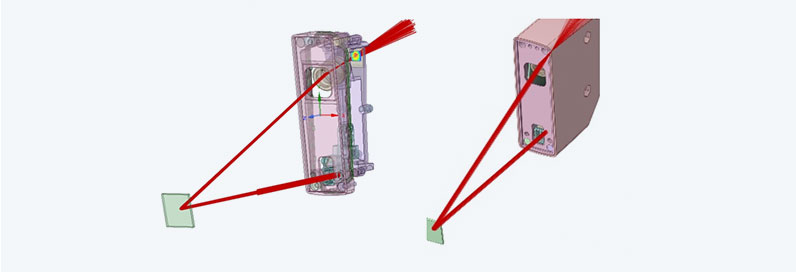

The optical sensors from ifm work with light in the red and infrared frequency range for electromagnetic information transmission. In order to be able to precisely represent the modulated light and the transported information independently of the mechanical influences outlined above, a tool for macroscopic optical simulation was introduced: Ansys Speos. This software has been part of the company’s portfolio since Ansys, Inc. acquired the development company in 2018. The goal was to couple the optical field with the structural-mechanical field and obtain an even more accurate overall picture.

Combined application with challenges

The full benefit of using multiple simulations for tasks, as is common at ifm, can only be realized if they are not carried out sequentially, but in combination. This is the only way to identify interactions and generate a realistic virtual image of the processes being analyzed. Since mechanics and optics are different physical domains and the software solutions were developed independently of each other, the desired integrated use was rather complex.

This meant that the structural-mechanical mesh had to be imported into Ansys Speos during coupling, making it necessary to re-mesh the optical components, which in turn affected the accuracy. It was therefore necessary to design the structural-mechanical mesh much more finely and uniformly, which resulted in an enormous increase in computation time.

Bernhard Schneider, Head of Technology and Process Engineering, ifm electronic gmbhThe mesh for the optical simulation once took 10 hours, but that’s now over. With the new workflow, a 20-minute coffee break is all it takes, and the mesh quality remains the same.

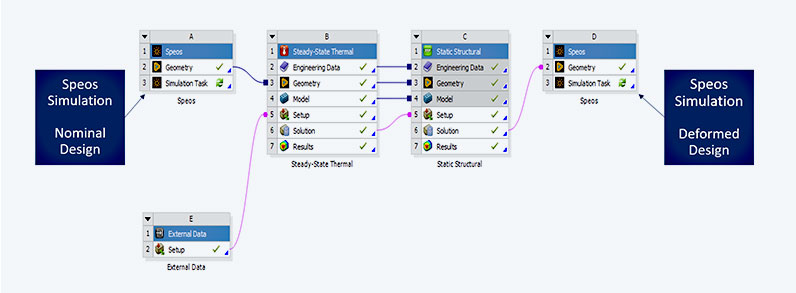

The optomechanical simulation workflow in Ansys

In order to become more efficient in this area, Bernhard Schneider and his colleague Orestis Hassomeris addressed this issue in regular discussions with CADFEM. The CADFEM team took advantage of its direct line to the development experts at Ansys to address the need for a lean optomechanical workflow. Since the importance of optomechanics is also increasing for other customers – and Ansys is committed to ensuring that its in-house solutions harmonize – the workflow was implemented with the involvement of ifm users.

Result: The deformed structural-mechanical mesh is decoupled from the optical mesh in Speos and instead is converted into a solid 3D body. This can be meshed in Speos, which reduces the time required for this step from 10 hours to just 20 minutes without compromising the quality.

How important is simulation for the development process in your company?

Simulation is very important for ifm. It has made it possible to greatly reduce the time required for both basic and product development, as important findings and design changes are incorporated into the development process at an early stage.

Why is it important for ifm to take thermal and structural-mechanical effects into account at an early stage in the development of optical sensors?

Thermomechanical strain and stresses have a significant effect on the optical axis or beam path of optical components. We use simulation to record this and can take countermeasures in a timely manner.

How would you rate the collaboration with CADFEM?

The collaboration has always been open, communicative, and solution-oriented.

Digital Persuaders

The products from ifm are closely linked to the digitalization and automation of industry and many areas of peoples’ lives. They make valuable contributions to better living and working conditions, sustainability, environmental and climate protection. The consistent use of digital tools in our own product development also fits in with this mission. This is why simulation is firmly anchored at ifm and is being further expanded.

The range of tools is broad. In addition to Ansys Mechanical and Speos, other Ansys products such as optiSlang (robustness analysis), Sherlock (life cycle calculation of electronics) or Zemax OpticStudio have long been part of the equipment of the central simulation team at ifm. ifm has secured access to additional modules and uncomplicated professional training for users through a long-term partnership with CADFEM Germany GmbH, which is also the first and most frequent point of contact for ifm on the subject of simulation and digital engineering.

About ifm

Measuring, controlling, regulating, and evaluating - when it comes to pioneering automation and digitalization technology, the ifm group of companies is the ideal partner. Since the company was founded in 1969, ifm has been developing, producing, and selling sensors, controllers, software, and systems for industrial automation as well as SAP-based solutions for supply chain management and store floor integration worldwide.

As one of the pioneers in the field of Industry 4.0, ifm develops and implements holistic solutions for the digitalization of the entire value chain “from sensor to ERP”.

Today, the second-generation family-run ifm group of companies is one of the global industry leaders with more than 8,700 employees. ifm combines the internationality and innovative strength of a growing group of companies with the flexibility and customer proximity of a medium-sized company.

ifm electronic gmbh

Author: Alexander Kunz

(CADFEM Germany GmbH)

Cover Images:

Right:© ifm electronic GmbH

Left: © ifm electronic GmbH

Published: December, 2023

Contact CADFEM