Micro optics for compact, lightweight, and customized lighting solutions

Visible Added Values

Micro Lens Arrays (MLA) represent a new generation in lighting technology. They pave the way for innovations through miniaturization, which brings benefits in functionality, safety, and freedom of design. To precisely design MLA for the individual application, SUSS MicroOptics uses optical simulations and robustness analyses within an efficient workflow.

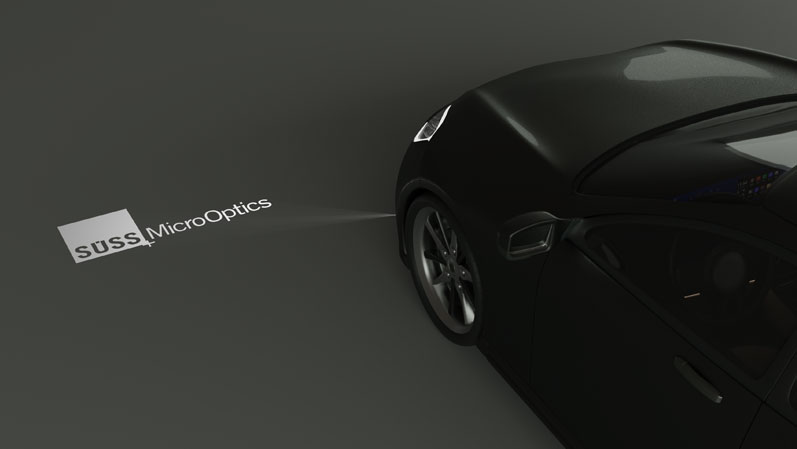

Lighting in cars goes far beyond headlights, interior and cockpit lighting. Today the latest lighting solutions focus on design, aesthetics, and emotion. Moreover, lighting effects can bring a unique appearance of the vehicle, which can influence purchasing decisions.

The rapid development in micro-optics provides a completely new scope in lighting technology. This is because micro-optical elements miniaturize the full lighting system in addition to increased distance and angle-independent depth of field. Their small space requirements, easy installation in any part of the vehicle, and flexibility of use have already inspired designers and engineers to create new and challenging design options - and the possibilities for innovation are far from exhausted.

Because the compact design of MLA also means weight reduction and energy efficiency, micro projectors are ideal for electromobility. Additional potential for performance optimization lies in individualized MLA, precisely tailored to the customer application. SUSS MicroOptics from Neuchâtel in western Switzerland addresses such issues using a simulation-based workflow with the Ansys tools Zemax OpticStudio and optiSLang. This fully digitalized process is not only faster and more cost-effective than other methods, but also delivers very reliable and precise results.

SUSS MicroOptics has enjoyed a productive and personalized collaboration with CADFEM experts, who have provided guidance on workflow strategy and efficient know-how transfer through targeted tutorials. This has proven invaluable for Optical Designers at SUSS MicroOptics, who now rely on Ansys tools and a proper knowledge base for projection-based MLA designs and optical simulations. Being that Ansys is a standard software suite in the automotive industry, SUSS MicroOptics benefits from streamlined interactions with their Tier-1 customers. This allows for faster and more efficient exchanges, making this motivating and friendly partnership an industrial success.

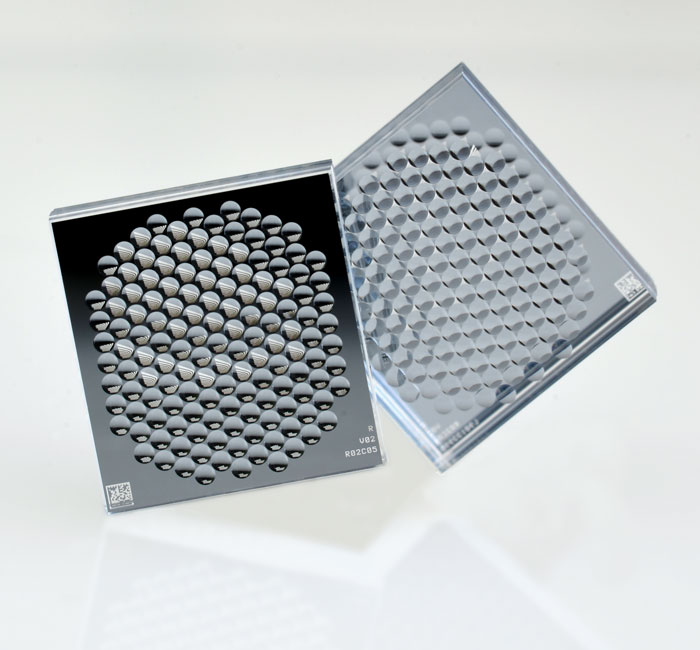

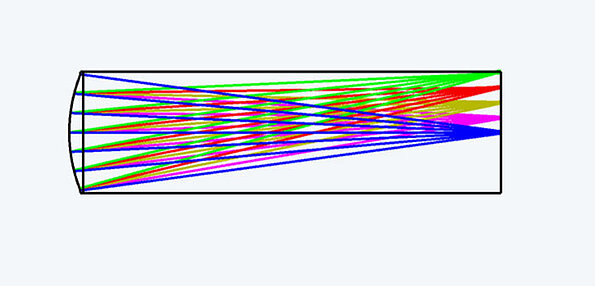

Micro Lens Arrays

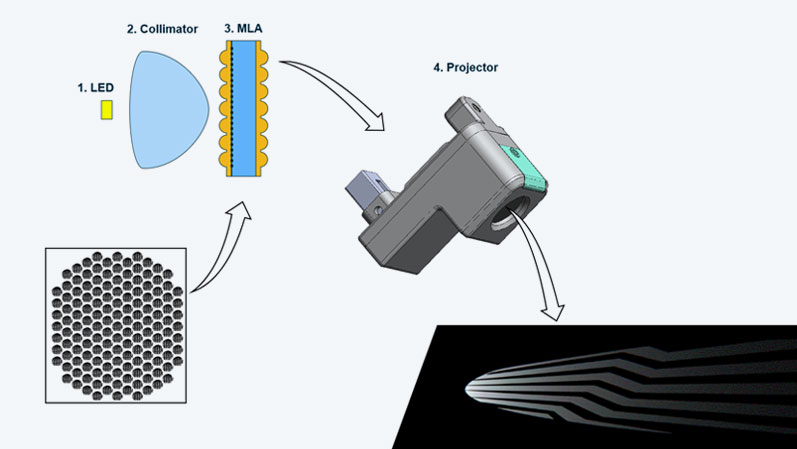

Micro Lens Arrays (MLA) are composed of many micro-optical elements and form an efficient optical system with LED. A sharp, integral image is generated by arranging and oversetting the micro projectors on the carrier plate. The application spectrum of MLA (or such optical systems) ranges from beam transformations in fiber coupling to the homogenization of lasers to the optimal bundling of diode stacks of identical wavelengths. The MLA size is between 5 and 50 mm. The structures in the architecture are significantly smaller than 1 mm.

Ground projection example

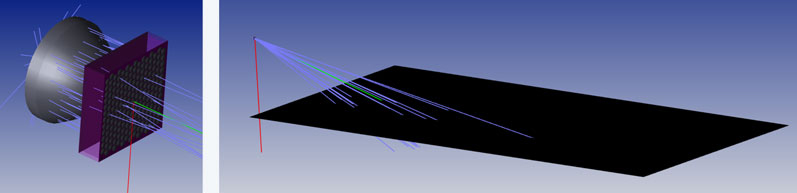

Ground projection created by optical systems with MLA have been around for several years. They project information, safety instructions, status messages or even graphic light design elements onto the floor. This provides information and additional safety features and creates a nice ambiance.

Examples from everyday life include the time display of household appliances or advertising messages in front of retail stores. In the automotive world, these are typically light strips that appear when getting out of a car. The possibilities of ground projections are endless. Increasing their performance to take on additional functions is a matter of further development and customizing the MLA for specific image or semi-dynamic patterns.

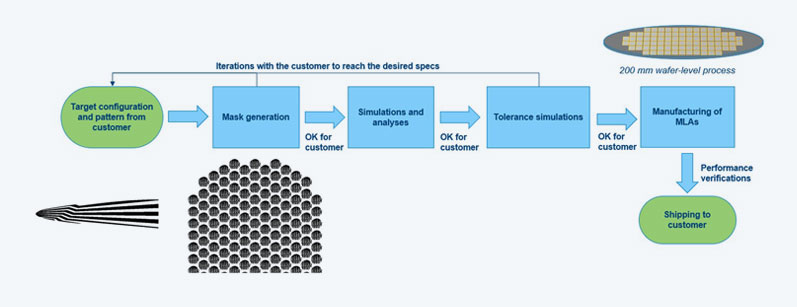

The simulation-based workflow from SUSS MicroOptics

Because the requirements grow with the number of applications, manufacturers must very quickly and precisely adapt the MLA to the specified profile. SUSS MicroOptics has developed a workflow for this, in which with the support from CADFEM Suisse, simulation technology plays an essential role: Ansys Zemax OpticStudio for the precise design of the micro projectors and their arrangement; Ansys optiSLang to ensure that manufacturing tolerances from the production process in terms of maximum quality of the MLA are taken into account.

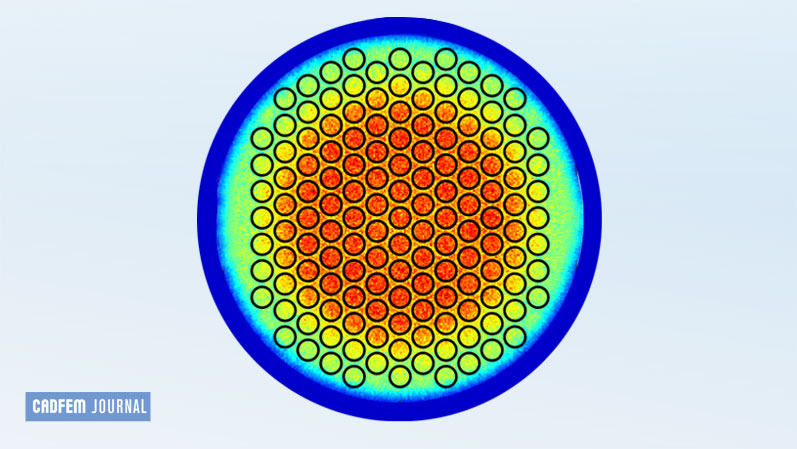

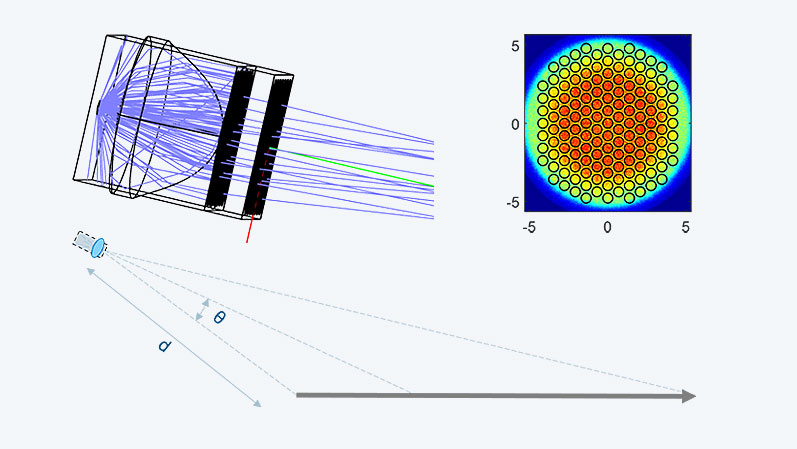

Optimization of the light beam with Ansys Zemax OpticStudio

The goal is the exact projection from a given angle. Since the light beam becomes inhomogeneous due to the angle and the distance to the projection surface, its effect must be optimized. In Ansys Zemax OpticStudio, such homogenization is achieved by a modified arrangement, which also includes the intensity of the various light channels. This is performed with automated macros and "reverse engineering", i.e. the software determines how the micro-projectors must be arranged and aligned on the array in order to achieve the desired floor projection, such as the ground projection.

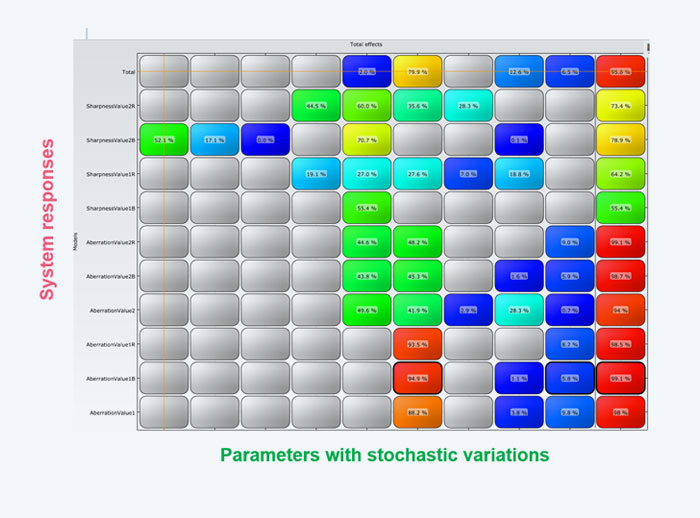

Consideration of manufacturing tolerances with Ansys optiSLang

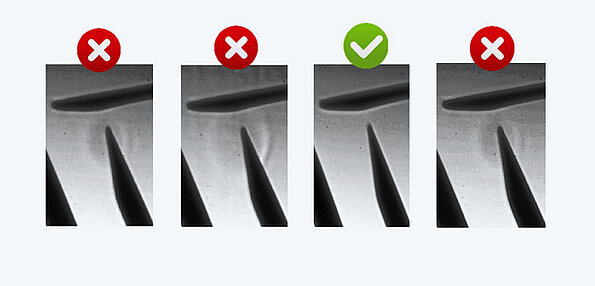

After the MLA elements are arranged and designed for the desired function with Ansys Zemax OpticStudio and customer accepts the result, another simulation step follows. Since every minimal deviation from the design of the optical system, has a negative effect on the quality of the ground projection, the manufacturing process of the MLA must also be considered.

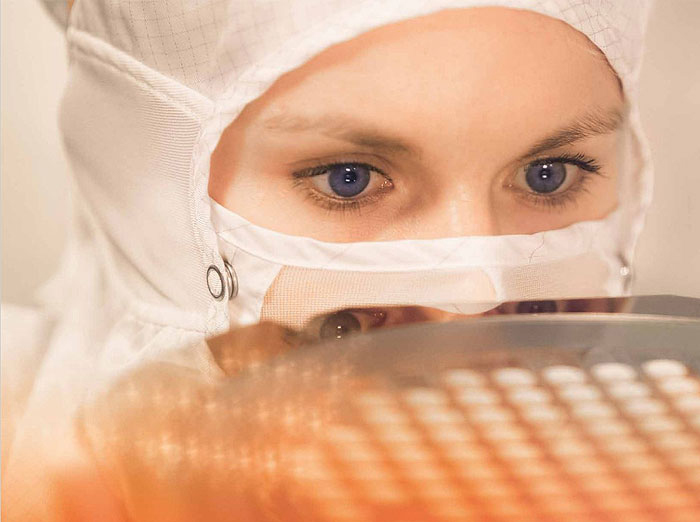

Despite the clean room laboratory and modern lithography technology at SUSS MicroOptics, variations in the production of the MLA are unavoidable and must be analyzed and included in the interest of a highly accurate end product.

To achieve this, Ansys optiSLang is used to determine the optimal (i.e. most robust) constellation for the final result from thousands of different combinations. The parameters are subject to stochastic variations and the measurable characteristics of the MLA such as sharpness, luminosity, and refraction.

About Süss MicroOptics

SUSS MicroOptics, headquartered in Neuchâtel, Switzerland, produces high-quality refractive and diffractive micro-optics elements for fiber coupling, collimation, and beam homogenization. The basis for this is an expert team with extensive experience in optical design, engineering, wafer-level manufacturing, metrology, and packaging. SUSS MicroOptics, a wholly owned subsidiary of SUSS MicroTec SE, is a qualified and key supplier for innovative photonic solutions in telecom, datacom, life science, laser, semiconductor equipment and automotive lighting. www.suss-microoptics.com

At the final destination

At the end of the process, the optical system is developed and optimized for a wide variety of scenarios for further use and production. The digital workflow developed by SUSS MicroOptics is fast, cost-efficient, and reliable. Ensuring that micro-optical systems can be individually adapted to their planned area of use, for example as a ground projection, and thus fully utilized to their potential, is a key competitive advantage.

Ansys Zemax OpticStudio and Ansys optiSLang are important tools for driving innovation further by unlocking the many other possible applications of micro-optical systems and optimally exploiting the capabilities of technology when it comes to precision in various forms

Note: This article is based on a presentation given by Giorgio Quaranta, SUSS MicroOptics, at the Swiss Forum CADFEM & Ansys 2022.

Robustness analysis of wafer-level optical systems (cadfem.net)

SUSS MicroOptics

Author: Alexander Kunz (CADFEM Germany GmbH)

Cover Images:

Right:© SUSS MicroOptics

Left: © SUSS MicroOptics

Published: October, 2023

Contact CADFEM