3 questions to Karsten Stoll, former CTO of WAGO Interconnection:

How WAGO faces new challenges in terms of technology, globalization, and digitalization

In early 2024, Tech-Exec Magazine invited Karsten Stoll, former CTO of WAGO Interconnection, to give comprehensive insights in his role in terms of leadership, today`s business challenges and how WAGO is facing them – e.g. by changing the way simulation technologies are used.

This is an excerpt of the interview “The vital component”, available on tech-execmagazine.com

Images: © WAGO

Mr. Stoll, in the rapidly changing technology landscape, how does WAGO Group approach innovation and what strategies do you employ to ensure continuous adoption of new technologies?

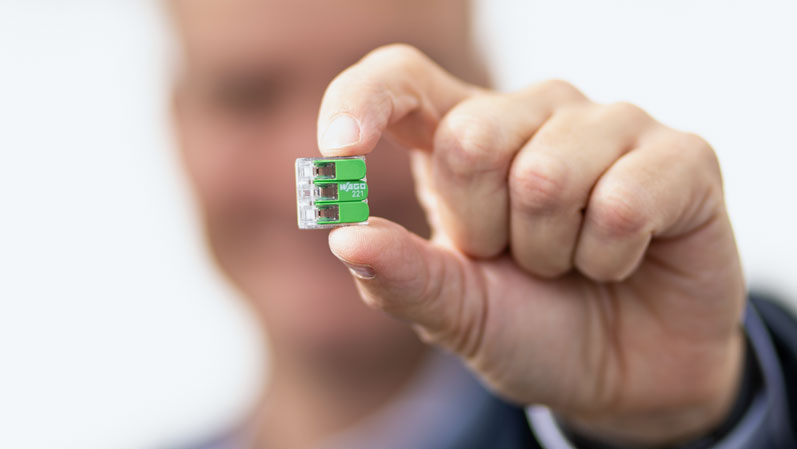

Our components are plastic, steel, and copper. We have a deep expertise in that. Technologies that develop quickly change the processes of our customers, as well as the tech we employ. So, we need a lot more expertise in digitalisation and what the customers are doing. Then we adapt our processes internally. When approaching the topic, we must ensure we keep what made us strong in the past, and then add new strategies around that to secure the future.

What do you see as key trends and challenges in the electrical interconnection and automation industry? And how is WAGO Group positioned to address them?

Currently, in the electrical interconnection and automation industry, we see an incredible change in the competitor’s landscape, mainly coming from China. Whereas we come out of a world that was local for global, developing basically everything locally in Germany and then distributing it across the world. We see a lot more local for local, more regulation, and a more digitally connected world. So we must learn to work more in networks not only with customers, but also with our core competitors, to solve general challenges with them.

Like the International Digital Twin Association here in Germany, we actively developed a new standard for communication of product data called ‘asset administration shell’. We’re moving together as an industry initiative within the International Digital Twin Association. And it is also a huge success for our customers – as download numbers are showing.

And of course, engineering itself will become more digital; for both hardware and software. Let me quote our partner CADFEM: “Digital engineering involves tapping the full potential of technical creativity, precise data models, and clever workflows. This ensures that a good idea results in an excellent product – for manufacturers, customers, and the environment.”

Karsten Stoll, former CTO Interconnection at WAGO, currently senior advisor.Simulation technology at WAGO is evolving from being a rigid part in the R&D process chain, to a technology that accompanies the complete product lifecycle and can be used by everyone involved in the engineering process.

Given the diverse applications of products, how do you foster collaboration and partnerships with other businesses?

Differentiation in our existing business of course means excellent hardware products, and excellent new digital products and services. If you think of that, we will only be able to succeed if we are a very digital company concerning our internal processes. Here is where we partner up with various strong partners. One very good example is CADFEM.

CADFEM is our long-standing partner in virtual product development technologies, especially advanced physics-based simulation. Simulation software enables us to develop, optimise and innovate our products digitally, on the screen. This does not only save a lot of time and money in product development – just think of the physical prototypes that do not have to be built, tested, and measured – it also helps our engineers to quickly test their ideas or compare hundreds of options, to be innovative – a key to differentiate ourselves.

Long story short: this is done by our engineers and CADFEM is our partner for software (we use Ansys), but also expert advice, seminars, customised development etc. CADFEM supports us to explore new application areas and accompanies us until they are fully implemented and dominated by our own engineers.

For example, simulation technology at WAGO is evolving from being a rigid part in the R&D process chain, to a technology that accompanies the complete product lifecycle and can be used by everyone involved in the engineering process. Having a comprehensive simulation-based digital model of each product (a “Digital Twin”) is a huge advantage and that is where we are going to with the expert advice of our partner CADFEM.

About Tech-Exec

Tech-Exec is an innovative digital multichannel media company that produces a portfolio of digital magazines, websites and social media platforms with exceptional content from the fields of technology, business and lifestyle.