Miele & Cie. KG

Forever better: Miele’s brand promise has held true for over 110 years. To keep it even today, Miele relies not least on simulation solutions from CADFEM.

Always better

“Forever better” was already stamped onto Miele appliances more than a century ago and it’s still the traditional brand’s central promise today. At Miele, quality, technology, comfort and design have always been the most important product development goals. Nowadays, engineers at Miele use powerful CADFEM simulation solutions to drive innovation forward, to optimally design components and assemblies and to safeguard the diverse products’ functions.

The requirements for household appliances for the kitchen and for laundry and floor care, as well as for appliances designed to be used in commercial enterprises or medical facilities, are constantly growing. “The fact that we are repeatedly awarded the title of Best Brand proves that we have implemented our understanding of our brand successfully,” says Jörg Kempe, a qualified engineer who is responsible for CAx technologies at Miele. “Another proof of this is that our customers have been shown to have the highest brand loyalty in the industry.”

Miele and CADFEM

Miele acquired initial experience with numerical simulations before the turn of the millennium by engaging external engineering service providers. Then, in 2005, Miele established its own in-house simulation operations. After trying out several alternatives, the company started introducing Ansys Workbench and had CADFEM train Miele employees in how to use simulation technology.

Simulation for continuous improvement

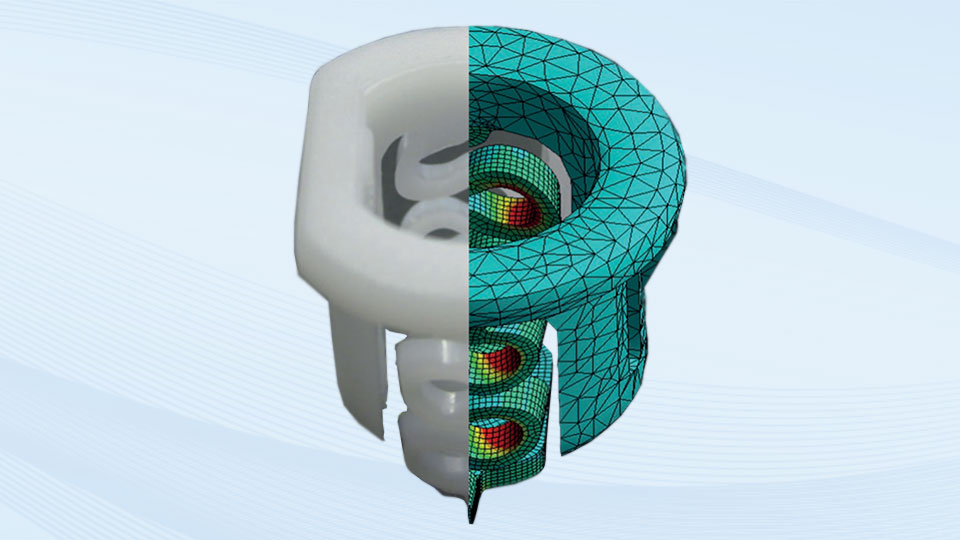

Simulation is used at Miele for an extremely wide variety of products and problems – and often leads to pioneering progress. “Over the years, by conducting various simulations we have acquired comprehensive knowledge, particularly about the washing units and the washing machines’ housings, that we can apply time and again. At the same time, the comparison with the tests carried out was continuously improved, so we now have very well-calibrated and fairly accurate simulation models,” explains Mr. Kempe.

Swift solutions

Matthias Hollenhorst, a Miele development engineer, believes the investigation of a compressor and its piping in a heat pump dryer is an excellent example of the benefits that simulation offers. During operation, the compressor torsionally vibrates at certain frequencies, which leads to the excitation of the piping. “For new projects, we can use simulations and optimization calculations to find robust solutions that offer a high level of reliability in a relatively short space of time,” highlights Mr. Hollenhorst. This approach has therefore become standard practice at Miele.

The current and future benefits of simulation

Due to the growing product complexity and increasing product diversity, the demands placed on Miele employees are forever rising. Simulations are becoming a vital tool in the product development process to ensure that this complexity and diversity are better overcome and that the requirements are met in a reasonable amount of time.

“If we used the trial-and-error method, we wouldn’t be able to maintain, never mind build on, our leading position in today’s global competitive environment,” affirms Jörg Kempe. “It would be too tedious, too time-consuming and too costly. In contrast, we use simulations at an early stage to gain a comprehensive understanding of the behavior of our future products and can design the individual assemblies and components in such a way that we create a robust design that also takes manufacturing tolerances into account. On that note, the various innovations and patents developed based on simulations also deserve special mention.”