MORe is the simulation software with which you can increase the performance of machine tools and reduce costs in a targeted manner while minimizing risk.

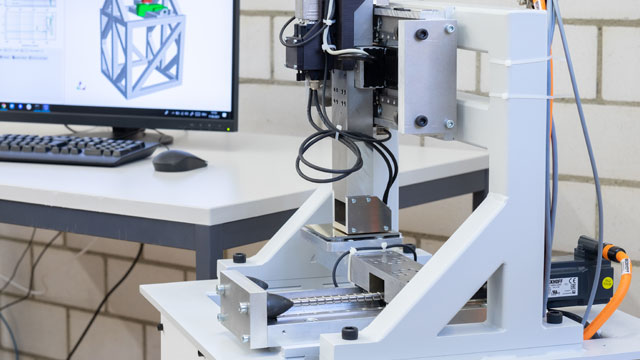

Efficient and user-friendly simulation of machine tools

Whether turning, milling, or grinding, or whether highly precise, highly dynamic, or cost-effective - MORe offers the perfect solution for the development of machine tools and production machines. Through the combination of an integrated controller, model reduction, and the coupling of mechanical and thermal behavior, MORe enables the analysis and optimization of various processes and performance criteria - quickly, precisely, user-friendly and without expert knowledge. With the Ansys Workbench solution, existing Ansys Mechanical models can be directly applied.

Development goals that are achieved with MORe

- Performance prediction

- Performance increase

- Reduction in manufacturing costs

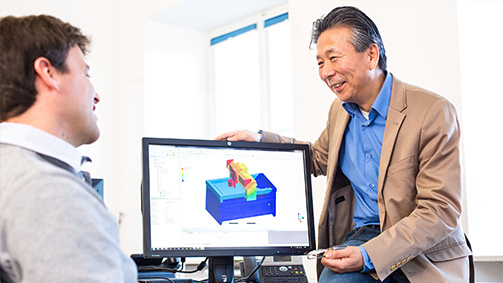

Using simulation to create a high-performance machine tool

MORe was developed by inspire AG, a CADFEM partner, for manufacturers of machine tools and other production machines. MORe contributes to performance optimization and cost reduction.

Product Highlights

- Fast and user-friendly system simulation of dynamic processes in machine tools and related systems

- Can be used without expert knowledge

- Accurate performance predictions

- Direct application of Ansys Mechanical models

- All-in-one simulation software: Model Order Reduction, A-priori error prediction, Integrated controller, Common machine couplings/drives, Thermomechanical analyses

More Workflow with Ansys

Physical domains

Mechanical

Simulate structural deformations and geometric accuracy of the complete machine including position dependency due to axis movements.

Mechatronic

Add motors and controllers and analyse the open-loop and closed-loop behaviour of the axes. Everything with compliant structural dynamics.

Thermal

Analyse the thermo-dynamic behaviour of the machine under consideration of heat sources, sinks, and convection.

Thermo-Mechanical

Calculate thermally induced deformations. Effects of position dependency, controllers, and encoder placement included.

More Related Information

CADFEM Contact

If you have any questions, feel free to get in contact with us.

The right solutions for your simulation projects

Simulation is everywhere and affects every industry. Since simulation requires more than software, CADFEM offers everything you need for successful simulation from a single source: software and IT solutions, consulting, support, engineering and knowledge sharing – always on the cutting edge.