Interview with the CADFEM Managing Director

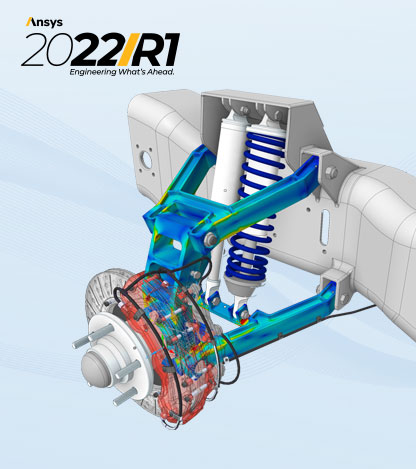

What makes Ansys 2022 R1 stand out, Erke Wang?

The latest version of the Ansys program family was released at the beginning of February. CADFEM specialists have already tried out the new features and further developments. We talked to Erke Wang, Managing Director at CADFEM GmbH, about what makes Ansys 2022 R1 special, what customers have in CADFEM and where the simulation journey is heading.

Erke Wang, what distinguishes the new Ansys release?

All the new and special features of Ansys 2022 R1 will be presented in detail in the CADFEM Update webinars. However, I would like to point out two of the highlights here:

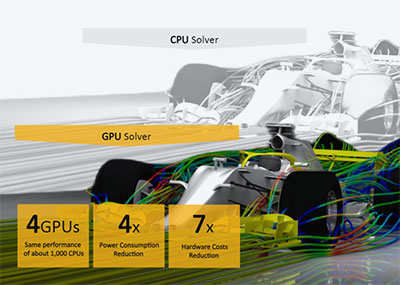

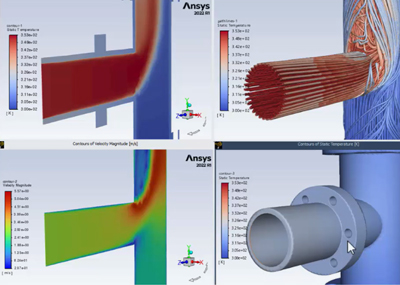

Highlight No. 1: the speed. Geometry modeling and meshing are noticeably accelerated and even qualitatively better. CPU parallelization also speeds up the computation itself. What’s added this time is the GPU. We particularly benefit from this in optics simulations with Ansys Speos, and CFD simulations with Ansys Fluent. This is great news!

Highlight No. 2: the “Workflow”. The software is becoming increasingly easier to use, even for complicated computation tasks, for example, in the field of acoustics. From acoustic excitation via acoustic vibration to acoustic energy, the process is now automated. These are the best prerequisites for a complete acoustic simulation. There is also good news for the design of electric motors. From now on, we can optimize several operating points simultaneously with Ansys Motor-CAD and Ansys optiSLang.

What opportunities does this open up for Ansys users?

The new features add application areas that many in the community have long been waiting for. A new solver and the previously mentioned additional speed mean that large models, in particular, can be simulated even more efficiently and parameter studies can be performed much more efficiently. The accuracy of the results also increases - without additional effort.

What is perhaps even more important for everyday simulation is that the new workflow is easy to handle. The new version makes all this immediately visible, palpable, tangible. Particularly important: due to the acquisitions of special suppliers in recent years, the entire spectrum for optical simulation now belongs to Ansys, for example, the illumination design for laser technology or sensor control. In line with this, we have invested in an optics laboratory at CADFEM. This means that our customers can also have the optical properties of material measured by us.

What does CADFEM offer its customers regarding Ansys?

In order for every CADFEM user to quickly get to know the new Ansys functions, we are once again offering our popular update webinars, for the major physical domains. Our experts have already intensively tested all new functionalities. We want to encourage our customers to use the new features. And if any questions arise, our support team is ready to help.

Erke Wang, Managing Director CADFEM GmbHThe software is becoming increasingly easier to use, even for complicated computation tasks.

How does CADFEM help customers simulate successfully?

We know: Simulation is more than software! Our claim is that we enable customers to use simulation technology in product development easily and efficiently through know-how transfer and engineering training. When introducing simulation, we not only advise our customers on the selection of an optimal software solution, but we also ensure that they benefit from our vast simulation expertise, which is represented by well over one hundred highly qualified CADFEM engineers.

In which direction is simulation developing?

What will simulation look like in 5 years? That will be exciting, because some trends are already discernible. I would like to mention 5 of them here. The first trend is that simulation is being used earlier and earlier in the development process. We need technology that enables simulation very quickly in the pre-development phase: GPU technology. With this technology, engineers can perform live simulations, i.e., calculations in a matter of seconds, and make reliable decisions at an early stage.

Trend 2 is process automation. It is a matter of not only considering individual physical domains in the simulation, but also of coupling several subdomains of physics. Or not only using one simulation tool, but rather several that automatically operate smoothly and efficiently together, as is the case with Multiphysics system simulations. Automation facilitates such processes. Simulation becomes scalable and ensures accuracy and stability.

Trend 3 is the use of knowledge gained in simulation. We want to implement it in the product development process. Through Simulation Process Data Management (SPDM for short), we can use all this information very well with PLM and PDM in the product development process.

Trend 4 is cloud computing, which means a robust and reliable cloud solution. It makes software and hardware available anywhere, anytime, on demand. The fifth and final trend on my list is just as important as the previous four: an intelligent solution based on AI technology.

What are the main drivers in engineering today?

I would like to mention two important points here: One is sustainability. We all know that products have to become more efficient, lighter and more eco-friendly. At the same time, they should be robust and durable. These parameters are not easy to reconcile. Simulation can do the job. We are convinced that simulation plays a prominent role in product development when it comes to meeting such sustainability requirements.

The other point, of course, is digital transformation. For every customer requirement, there is a digital method – in our case for validating and testing – so that groundbreaking decisions are made earlier. Decisions that make the entire product development process much more efficient.

And that applies to every product. Let’s take a drink bottle. A company wants to develop it. It must have a good design, with as little material as possible and still be robust. The commissioned designer can use simulation to check and evaluate the requirements from the very beginning and at any point in time. This makes the entire development process much faster and more efficient.

How do CADFEM and Ansys contribute to digitalization?

This answer also has two parts. First, simulation is present throughout the entire product lifecycle. Simulation is not only found in development, where it is expected and where I consider it indispensable, but also in production, especially with new methods (keyword: 3D printing). Such new methods become even more efficient with simulation. Simulation is even valuable in operations and service (keyword: digital twin). With sensors and simulation, we will be able to understand and observe products much better in the future.

That was part one of the answer. Here is part two: simulation can be integrated with other tools throughout the development phase via the previously mentioned Simulation Process Data Management (SPDM) method.

Erke Wang, Managing Director CADFEM GmbHOur claim is that we enable customers to use simulation technology in product development easily and efficiently.

How can CADFEM support in times of pandemic?

What can we do for businesses, especially in challenging times like the pandemic, when many are working from home? We all know that companies with a digital infrastructure have benefited from this during the crisis. The establishment and reliable availability of the cloud solution with software and computing resources I mentioned earlier is one contribution CADFEM makes to keeping things going for our customers in their home offices. Another is continuing education. With the CADFEM eLearning online trainings, engineers can easily obtain further training on the topic of simulation from the comfort of their own home.

Next building block: live simulation. A fast way to discuss new ideas with colleagues or customers, test variants and communicate on new products, even from home. CADFEM turns the home office into a digital lab.

Thank you, Erke Wang, for this information.

CADFEM: Ansys Elite Channel Partner. Since 1985.

CADFEM and Ansys are connected by a close partnership that has lasted for decades. As an Ansys Elite Channel Partner, CADFEM customers from industry, research and education receive, in addition to Ansys software, add-on solutions, knowledge offerings and services for successful simulation.

Managing Director Erke Wang has been with CADFEM from nearly the beginning.