FE calculation of tightness and torque for a butterfly valve

Sector: Machinery and plant engineeringSpecialist field: Structural mechanicsInterApp offers high-quality valves and accessories made of metal and plastic. For the optimization of a butterfly valve, the company turned to CADFEM to perform parameter studies with an FE model.

Summary

Task

The customer’s goal is to be able to calculate the tightness and torque of butterfly valves using FE simulation and to identify the main factors influencing these two target values.

Solution

For validation, the test rig was simulated with leakage and torque tests in ANSYS Workbench for comparison with measurement results.

Customer benefits

With the simulation model, parameter studies are possible in order to optimize the butterfly valve. The number of tests of prototypes in the laboratory as well as the development time can thus be significantly reduced in the future.

Project Details

Task

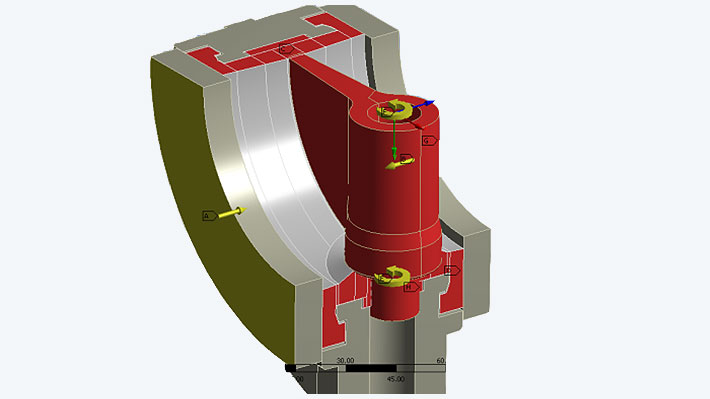

InterApp Technics AG manufactures butterfly valves for controlling the flow of liquids in pipelines. Butterfly valves essentially consist of an elastomer sleeve and a rotatable metal butterfly valve. When closed, butterfly valves should be tight up to a specified unilateral internal pressure on the one hand, and on the other hand be able to be opened with the lowest possible torque. Due to the compression between metal and elastomer, which is necessary for the tightness, high opening torques occur. The butterfly valve is opened by a pneumatic or electric actuator, which represents a significant cost factor in the overall design. The customer's goal is to be able to calculate the tightness and torque of butterfly valves using FE-simulation and to identify the main factors influencing these two target values. Under these conditions, the butterfly valves can be optimized in further steps.

Customer Benefit

A validated FE model is available to the customer, which can be used to calculate the tightness and the torque required for opening. This enables parameter studies to be carried out in order to optimize the butterfly valve. The number of tests of prototypes in the laboratory as well as the development time can thus be significantly reduced in the future.

Solution

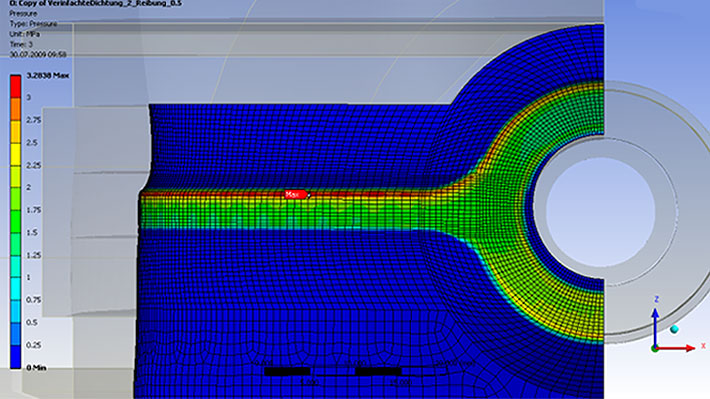

For validation, the test rig was simulated with leakage and torque tests in order to compare with measurement results. The butterfly valve was modelled as a volume model (¼ model) and the non-linear behavior of the EPDM elastomer seal was modelled with a hyper-elastic material model. As a result, the calculation provided the torque curve as a function of the opening angle and the remaining contact pressure between the sleeve and the valve at 16 bar pressure in the closed state.

Images: © InterApp Technics AG