Lifetime prediction for the efficient design of electronic components

Sector: Consumer goods/durable goods, Electrical engineering/electronicsSpecialist field: Structural mechanicsBJB is a specialist in the field of lighting solutions for industry and household and has stood for reliability and innovation for 150 years. Lighting components are developed and produced with the most modern technical solutions. Simulation plays a decisive role here in order to plausibly compare design ideas and implementation proposals in advance.

Summary

Task

For a new LED light based on the COB (Chip-On-Board) principle, BJB wanted to test the contact design with a new approach. According to the conservative method, the contact design would have to be tested for weeks on the test bench or analyzed for several days with classical FEM simulation to evaluate the load capacity and lifetime of this contact. However, BJB decided to apply a new approach with Ansys Sherlock and was able to reduce the effort to about one working day with the help of CADFEM.

Solution

The revolutionary approach used by Ansys Sherlock delivers good accuracy and significantly reduced modeling and computational effort compared to a classical FEM approach. For the standard electronic components, an algorithm for damage or failure calculation is used which performs relatively easily a good/bad evaluation.

Customer benefits

BJB was able to carry out the efficient design of the electronic components within one day, which would otherwise have taken at least one week with a classic FEM tool. Thus, many variants can be checked at the design stage and the time-to-market can be reduced significantly.

Project Details

Task

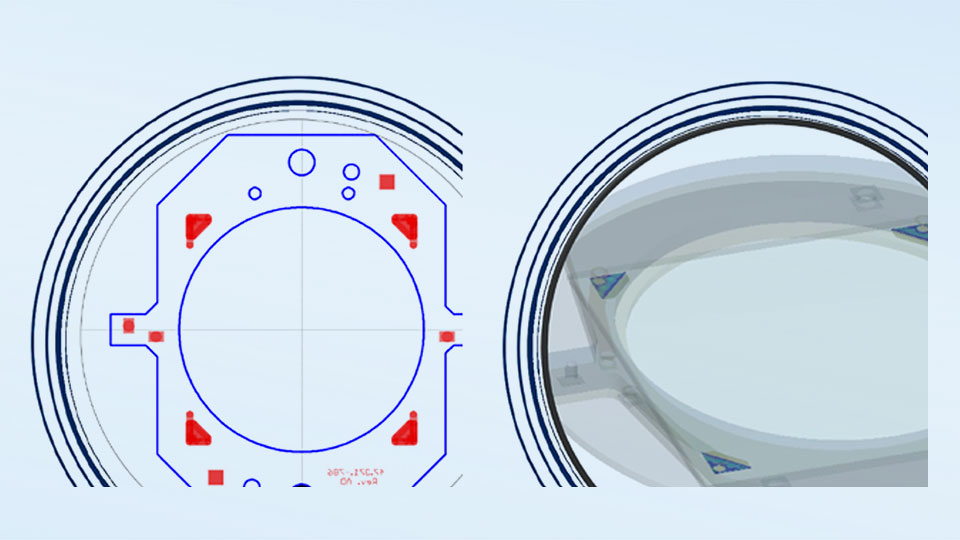

For the design of a Chip-On-Board (COB) LED light, a statement about the lifetime of the contact system is required.

Currently, a direct solder joint contact is used, for which BJB has no previous experience with regard to load capacity and life expectancy. Time-consuming tests would be expensive and inefficient. Therefore, a simple and fast solution was sought to evaluate the direct contact in the development phase.

Customer Benefit

With Ansys Sherlock, the task was solved within one day. The time gained compared to physical testing (several weeks) and classical FEM (several days) was used to optimize the design by varying the parameters, since each design was evaluated in only a few minutes.

Solution

With Ansys Sherlock, a fast and efficient design of the electronic components at BJB could be carried out in advance. The lifetime prediction of the cyclic load shows good agreement with Ansys Mechanical.

Due to easy handling (use of preprogrammed elements), fast computing times and high quality of results Ansys Sherlock is suitable for the design of electronic components especially in the design phase. Even the evaluation of the entire assembly before the start of production can reveal findings that can improve the quality.

Images: © BJB