Quickly evaluate customer requirements with simulation

Sector: Electrical engineering/electronicsSpecialist field: Scalability of simulations, Structural mechanicsThe diverse connector systems from ODU are often equipped with highly specialized contact technology. To further improve the comparatively simple functional principle, a workflow for systematic variant studies with the Ansys software portfolio was developed together with CADFEM.

Summary

Task

Different requirements for a robust contact technology require individual customer solutions. In addition to the typical list of requirements for insertion and withdrawal forces, there are a large number of other design and manufacturing parameters that influence the final product behaviour.

Solution

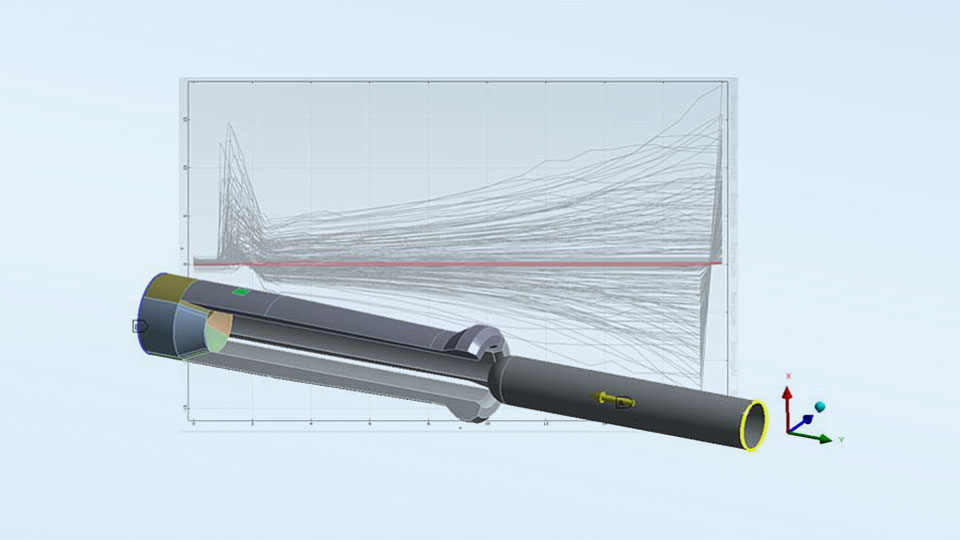

The implementation was done with ANSYS Mechanical for the structural-mechanical analysis and ANSYS optiSLang for the control of the variant study. The analyses are based on parameterized FEM models of the connectors for the automated calculation of the design variants. Thus, further "what-if" analyses can be performed at the push of a button.

Customer benefits

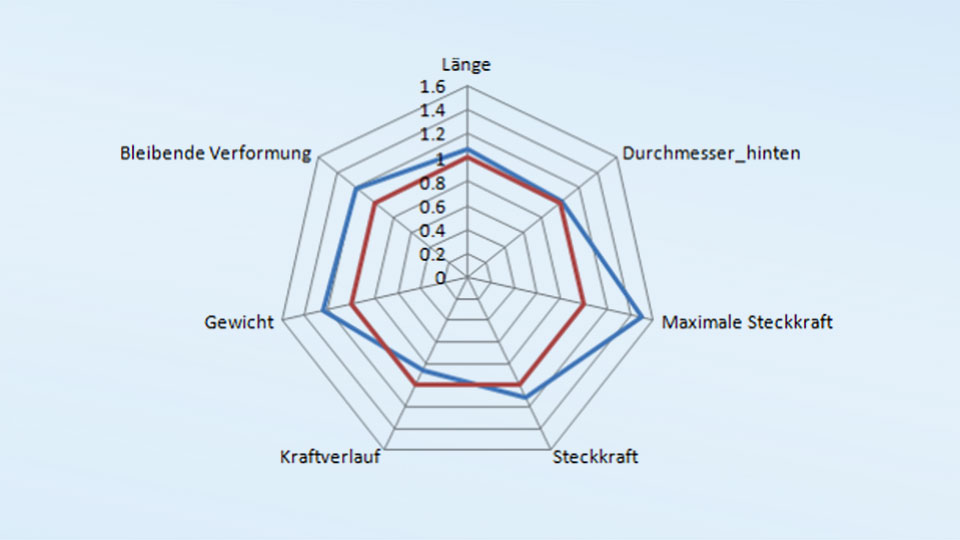

Sensitivity analyses can be used to identify the main factors influencing component functions. Thus, specific adjustments are possible depending on the requirements. Unnecessary optimization loops are eliminated, which saves production and laboratory capacities and shortens development time. Customer requirements can be evaluated more quickly.

Project Details

Task

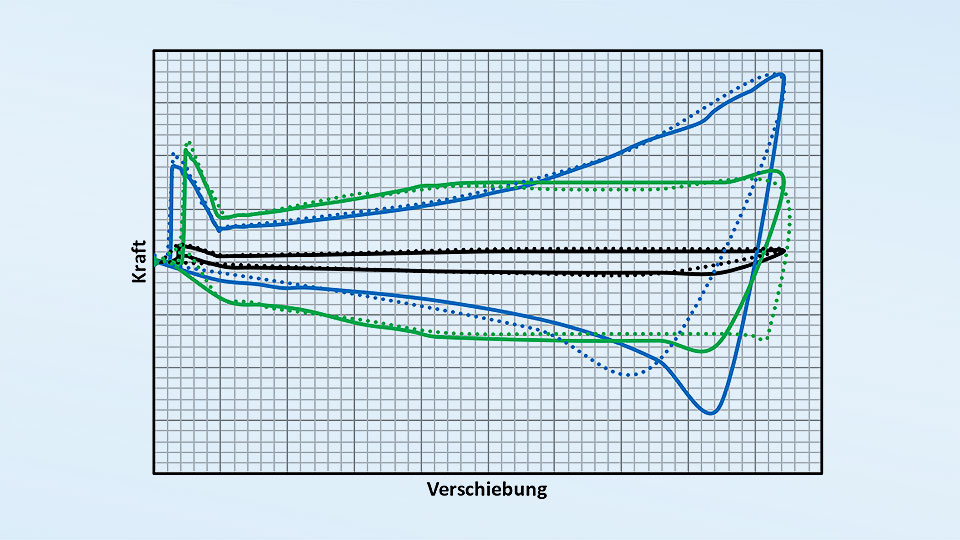

The diverse connector systems from ODU are often equipped with highly specialized contact technology. Each type of contact is precisely tailored to the respective application in terms of functionality and properties, with a wide range of diameters and connection types available. This results in the most diverse requirements for robust contact technology, which must be fulfilled individually for each case. In addition to the typical list of requirements for insertion and withdrawal forces, there are a large number of other design and manufacturing parameters that influence the final product behaviour. To further improve the comparatively simple functional principle, a workflow for systematic variant studies with the Ansys software portfolio was developed together with CADFEM.

Customer Benefit

"We at ODU can use sensitivity analyses to identify the main factors influencing component functions. This allows targeted adjustments of individual set screws according to requirements. In addition, unnecessary optimization loops can be avoided, which saves production and laboratory capacities and significantly shortens development times. The creation of a virtual substitute model also allows better comparison with laboratory measurement data and enables us to quickly evaluate customer requirements".

Bernhard Bauer, Otto Dunkel GmbH

Solution

The implementation was done with Ansys Mechanical for the structural-mechanical analysis and Ansys optiSLang for the control of the variant study. The analyses are based on parameterized FEM models of the connectors for the automated calculation of the design variants. In the context of a sensitivity analysis, those parameters could be extracted which are decisive for the response behavior, e.g. the insertion force. With the reduced parameter set, a virtual connector model was created using the "Metamodel of Optimal Prognosis" (MOP). Integrated in MS Excel, this allows further "what-if" analyses to be carried out at the push of a button in advance of future customer-specific developments.

Images: © ODU