Simulation of a dosing valve in packaging technology

Sector: Consumer goods/durable goodsSpecialist field: Structural mechanicsBERICAP GmbH, with headquarters in Budenheim, is one of the world’s leading manufacturers of plastic closures in the packaging industry. CADFEM used FEM analysis to find the optimal variant of a dosing valve.

Summary

Task

Depending on the fluid to be dispensed, various valves are to be developed for a hinged lid with an integrated dosing valve, considering that manual force is required for dispensing.

Solution

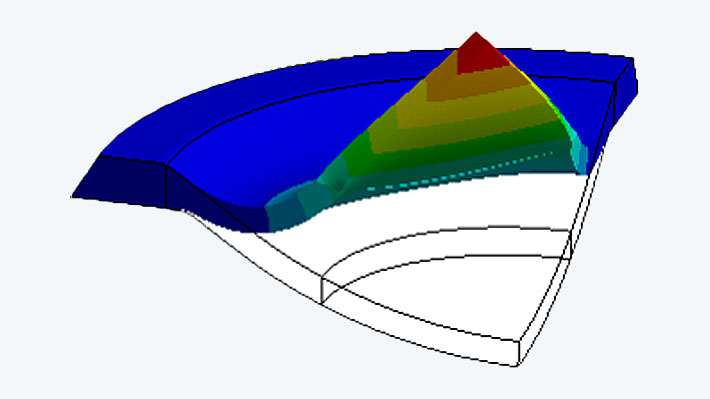

An efficient quarter model in Ansys Mechanical enabled multiple variant studies and allowed for an accurate prediction of the fluid pressure at which the valve would suddenly open.

Customer benefits

Based on the elaborate analysis strategy – and with the help of parameterization – a large number of design variants can be automatically analyzed in order to find the most suitable solution.

Project Details

Task

BERICAP GmbH, with headquarters in Budenheim, manufacturers plastic screw caps. Among the many seal types is the hinged lid with integrated dosing valve. Depending on the fluid to be dispensed, various valves are to be developed for a hinged lid with an integrated dosing valve, considering that manual force is required for dispensing. Tightness and ease of dosing were two competing target variables. CADFEM performed an FEM simulation with the aim of calculating and optimizing the fluid boundary pressure of the folding process. The nonlinear static analysis of the folding process illustrates a snap-through problem in combination with a nonlinear-elastic plastic behavior. Therefore, the influence of the design geometry of the valve on the opening behavior was analyzed.

Customer Benefit

Based on the elaborate analysis strategy – and with the help of parameterization – a large number of design variants can be automatically analyzed in order to find the most suitable solution. By optimizing the geometry and predicting the operating force for the dispensing valve, the number of prototypes required can be reduced. Since a delivery time of around six weeks can be expected for the mold of a sample cavity, BERICAP can save both development time and costs through simulations using the virtual prototypes.

Solution

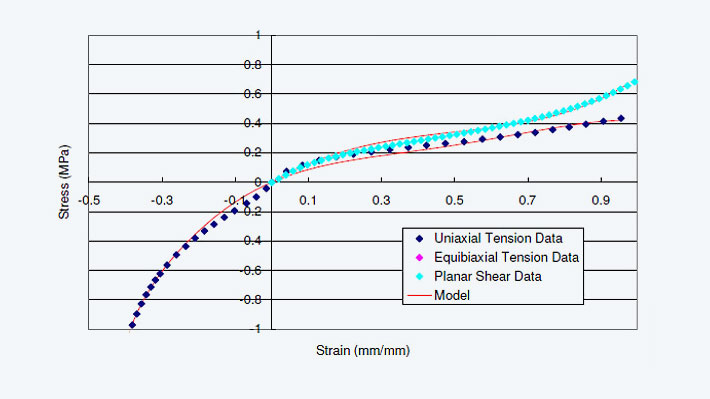

Prior to virtual testing, material samples of the membrane plastic were examined in the DatapointLabs laboratory. The measurement results were provided along with fitted material parameters for the isotropic hyperelastic material laws available in ANSYS. Based on the strain area occurring in the folding process and the residuals of the measurement curve fitting, a suitable material model could be selected for the membrane simulation. An efficient quarter model in Ansys Mechanical enabled multiple variant studies and allowed for an accurate prediction of the fluid pressure at which the valve would suddenly open. While solving the instability problem, an improved arc length method provided high robustness in the analysis of the fluid pressure displacement curve beyond the snap-through point.

Images: © BERICAP