System simulation for higher data rate in MP telemetry systems

Sector: Machinery and plant engineeringSpecialist field: MultiphysicsWith system simulation in Ansys Twinbuilder, the pulse generation in steerable drilling tools can be optimized. For this purpose, the coupled behavior of mechanical and hydraulic components of the drilling fluid is analyzed under different operating conditions.

Summary

Task

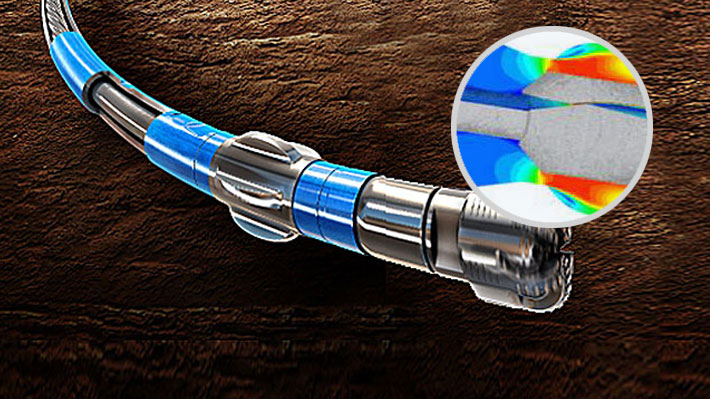

Scientific Drilling is developing steerable drilling tools that can communicate with equipment at the ground surface during the drilling process via pressure pulses in the drilling fluid. A hydraulic-mechanical valve unit serves as the core element. To increase the data rate, the influences on the pressure pulses are examined with simulations.

Solution

The examination of pressure pulses requires an analysis of the system behavior at different volume flows as a function of pumping capacity and drilling depth. This requires models for a volume-flow-independent characterization of valves. This can be achieved by using Modelica components.

Customer benefits

With system simulation, various dynamic processes for generating the pressure pulse were examined. This allowed the previous understanding of the system to be expanded, and the simulation results also served to identify further potential for improvement.

Project Details

Task

When developing crude oil and natural gas deposits, controlling the course of drilling plays a decisive role in its subsequent productivity (see also CADFEM Journal 2/2019, “Systematically Drilled”). For this purpose, Scientific Drilling is developing steerable drilling tools at the Celle site, which can communicate with systems on the ground surface by using pressure pulses in the drilling fluid during the drilling process (mud pulse or MP telemetry). A hydraulic-mechanical valve unit serves as the core of this technology.

The data rate of current MP telemetry systems is limited and too low for the growing amounts of data that have to be transmitted over greater distances in increasingly shorter time intervals. In order to increase the data rate, the various influences on the pressure pulses - such as volume flows and valve properties - are to be examined in a system simulation.

Customer Benefit

Using the system simulation, various dynamic processes for generating the pressure pulse could be examined. The previous understanding of the system was expanded, and the simulation results were also used to identify potential improvement options.

- By using the Modelica components, it was possible to reduce the number of CFD analyses required.

- The resources freed up in this way can be used directly for the examination and further development of the design of essential components - for example, the valves.

- Existing potential for improvement in terms of system behavior can be identified and compared.

Solution

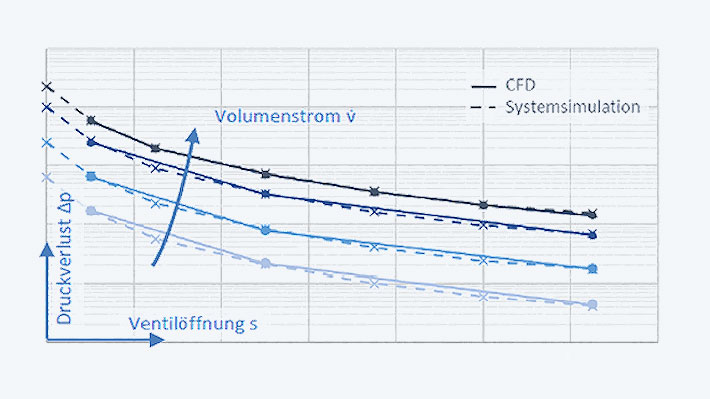

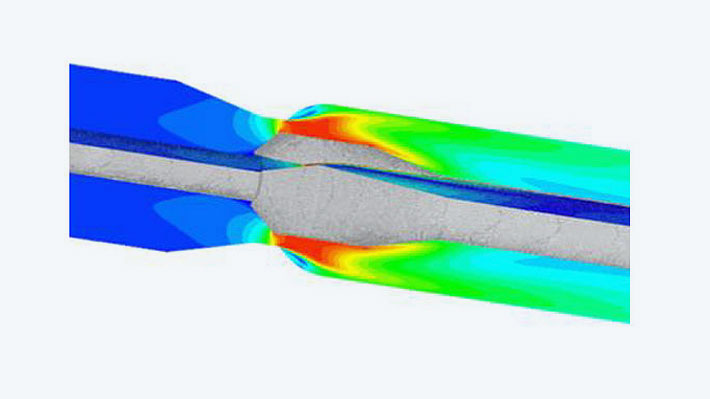

As part of the system simulation with Ansys Twinbuilder, the pulse generation, i.e., the coupled behavior of the mechanical and hydraulic components, was examined. For this purpose, the valves for pressure pulse generation were characterized using several CFD analyses with Ansys Fluent. This way, the pressure losses could be determined depending on the valve position for a selected volume flow and made available for the system simulation.

However, examination of the pressure pulses requires an analysis of the system behavior with different volume flows depending on the pumping capacity and drilling depth. In order to reduce the required number of CFD analyses, the system model was adapted with elements from the Modelica Standard Library, which enabled a volume-flow-independent characterization of valves. Thus, the numerical simulation results can be complemented by the analytical approach of the Modelica components in order to represent a wide range of operating conditions at low numerical effort.

Images: © Scientific Drilling