Transient Sound Emission Analysis during Offshore Pile Driving of Monopiles

Sector: Machinery and plant engineeringSpecialist field: Acoustics, Structural mechanicsMENCK provides specialized hydraulic pile driving solutions. In the swiftly growing offshore wind industry, sound emission, especially under water, is a growing concern.

Summary

Task

In order to determine the peak sound pressure at certain locations in advance a detailed numerical simulation of the transient driving impact and the related hydro-acoustics is necessary.

Solution

Using the Ansys Workbench environment, a flexible dynamics model was set up to assess the underwater noise emission from hammer impact, through the pile and into the surrounding area.

Customer benefits

High noise levels are easily assessed through this simulation and hence appropriate noise protection systems can be developed.

Project Details

Task

In the swiftly growing offshore wind industry, sound emission especially under water is a growing concern. In order to determine the peak sound pressure at certain locations in advance a detailed numerical simulation of the transient driving impact and the related hydro-acoustics is necessary. As an example, a large monopole with a conical shape (total length 50m, diameters 3m - 4,75m, wall thickness 50mm) and installed with the hydraulic MENCK hammer MHU 800S was investigated. The impact energy is 820kJ which generates an impact force of 85MN. The final penetration depth of the pile is 20m and the water depth is 22m.

Customer Benefit

High noise levels are easily assessed through this simulation. Hence appropriate noise protection systems can be developed such as enclosing the pile in a “bubble curtain” or an auxiliary pile with air chambers, treatment of the pile surface or other solutions.

Solution

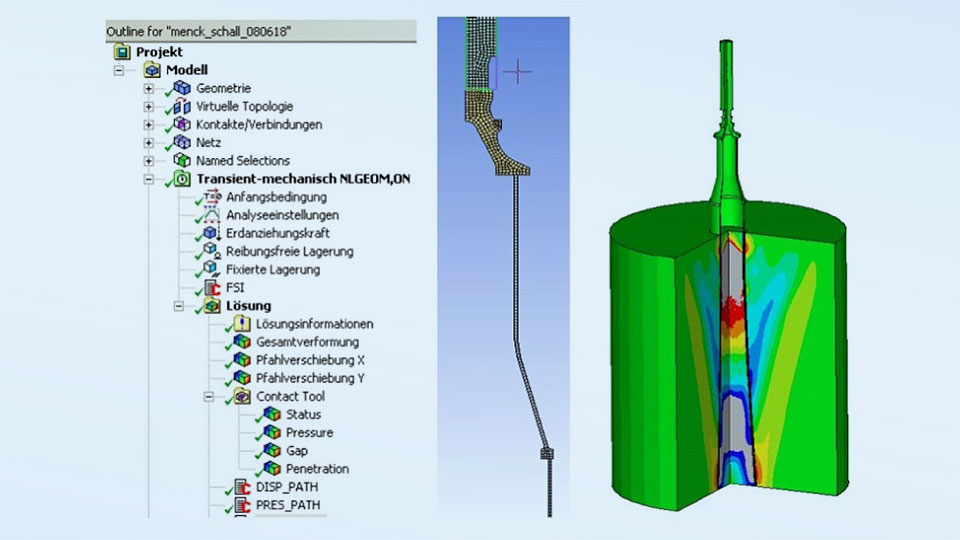

Using the Ansys Workbench environment, a flexible dynamics model was set up to assess the underwater noise emission from the hammer impact, through the pile and into the surrounding area.

FE model:

- Nonlinear contacts.

- Ansys acoustic elements simulate the water environment.

- Two-way algorithm (strong, matrix coupling) simultaneously calculates the interaction of Fluid & Structure (FSI) for structural displacement and sound pressure values.

Results:

- Axial displacement produces radial bending vibration in the pile. Vibration within the pile is responsible for sound emission.

- A snapshot of a fixed point-in-time shows the sound pressure wave from the hammer impact down through to the seabed in figure 2.

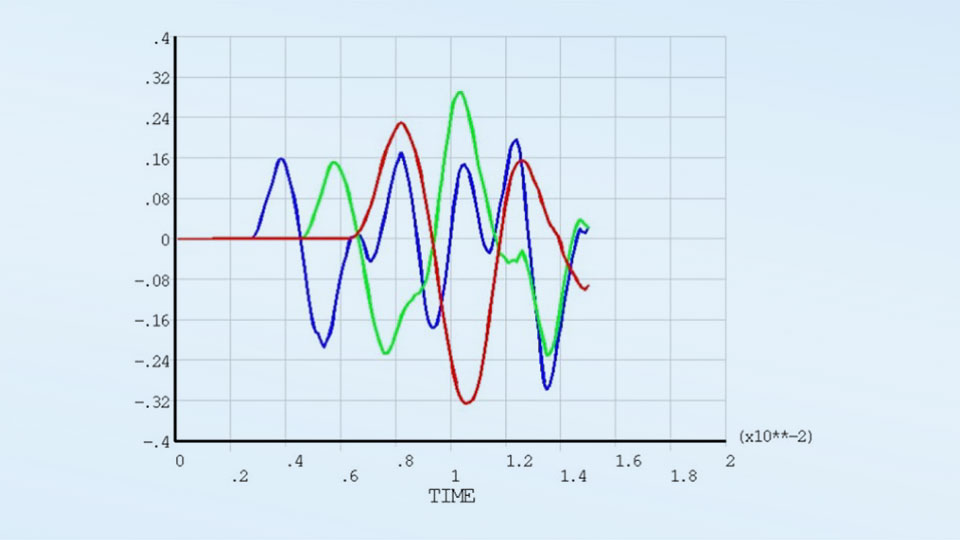

- Figure 3 shows the three simulated microphone signals.

Images: © Menck