Klubert + Schmidt GmbH

Klubert + Schmidt is a company that specializes in exhaust flaps for commercial vehicles. To achieve maximum performance, K+S engineers use state-of-the-art simulation solutions from CADFEM.

Klubert + Schmidt simulates exhaust flaps

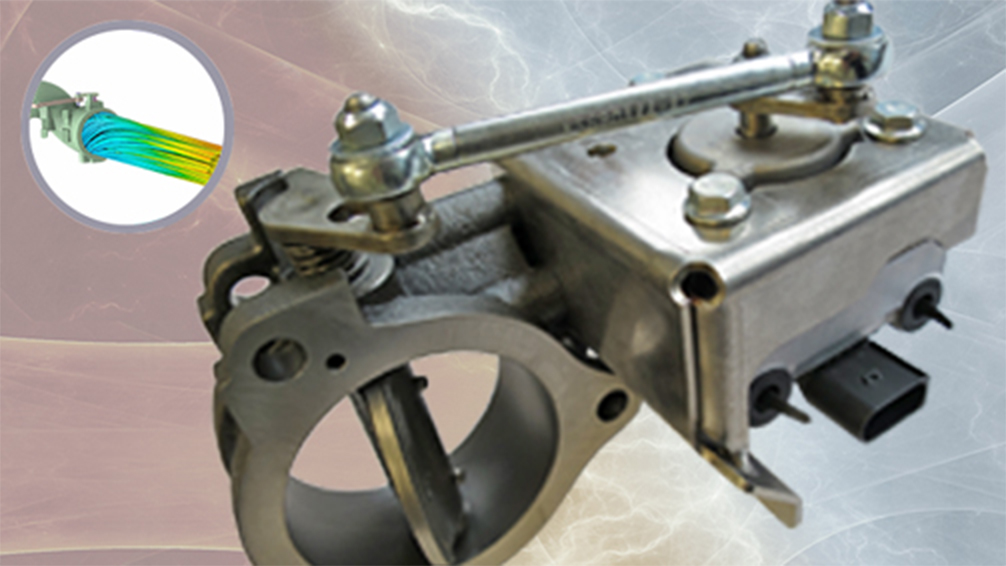

Klubert + Schmidt, a family-run company established in 1945, sees itself as a competent development partner and reliable series supplier of exhaust flaps and hot-side exhaust gas recirculation valves that are used particularly in mid-range and heavy commercial vehicles.

In commercial vehicles, exhaust flaps are used as the third independent braking system that is mandated in Germany for buses and trucks with an admissible total weight of over 5.5 t and over 9 t respectively. K+S throttle valves do more than just reliably meet the safety requirements expected of such systems. They also make a noticeable contribution to cutting vehicles’ operating costs and reducing their pollutant emissions using a variety of effects.

To further improve its products’ performance, Klubert + Schmidt now relies on modern multiphysicssimulation solutions from Ansys and its cooperative relationship with CADFEM in its product development operations.

Klubert + Schmidt and CADFEM

When the Klubert + Schmidt designers decided to take the next step in product development, they initially thought of having simulation software for fluid dynamics analysis integrated into their CAD system and consulted various suppliers operating in this field. But after CADFEM presented the possibilities of Ansys AIM, its new multiphysics simulation software, they were won over by the advantages of this far more powerful solution.

Convincing intuitive ease of operation and good user guidance

Richard Krellner, K+S’s Design Manager, explains: “We introduced Ansys AIM to link different physical domains – particularly structural mechanics domains that couples with fluid mechanics ones. Our technicians can therefore also use multiphysics simulations even if they have no special simulation knowledge. Above all else, we were won over by Ansys AIM’s intuitive ease of operation, integrated workflow templates and good user guidance.”

Multiphysics simulations with Ansys AIM are increasingly becoming an integral part of product development at K+S and are used as quality gate elements that have to be met to proceed to the next project phase. Many test setups for the test rig and some of the physical prototypes are no longer required – which saves time and money to boot. What’s more, new ideas can be analyzed more efficiently and implemented more effectively.”

Project-related training

CADFEM accompanied the introduction of Ansys AIM with company-specific and project-related training courses with six designers. A specific development project, in which Klubert + Schmidt analyzed the behavior of an engine brake that had previously undergone a variety of measurements on the test bench, formed the basis of this. The simulation results could therefore be validated very well with the extensive measurement data.

“The training course and pilot project carried out by CADFEM meant that Ansys AIM was implemented quickly at Klubert + Schmidt, so we can now meet the increased simulation requirements more thoroughly. On the whole, the expanded simulation approach underlines our technical expertise and Klubert + Schmidt’s innovative potential,” says Richard Krellner, summing up the successful introduction and benefits in product development.