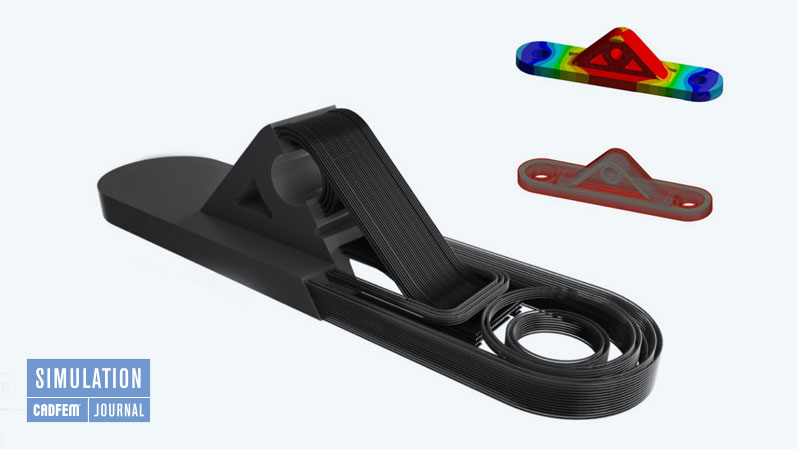

Additive Print simulates and automatically compensates for problems that can occur in metal 3D printing, such as recoater arm interference (blade crash) and component distortion.

Free Trial VersionAnsys Additive Print simulates stresses and distortions in metal 3D printing

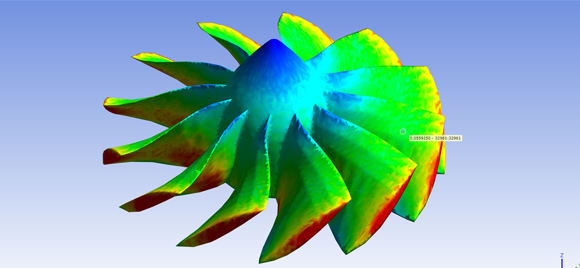

Additive Print simulates the construction process in metal 3D printing and can identify critical points in advance using thermal and mechanical simulation, enabling the user to introduce appropriate countermeasures at an early stage.

Ansys Additive Print for AM printing

Avoid misprints in metal 3D printing with Ansys Additive Print

Additive Print can be learned very quickly and is therefore ideal for users who are not simulation experts. All simulations relevant to the AM printing process – e.g. blade crash, deformations, stresses and temperatures – are detected and visualized.

Product Highlights

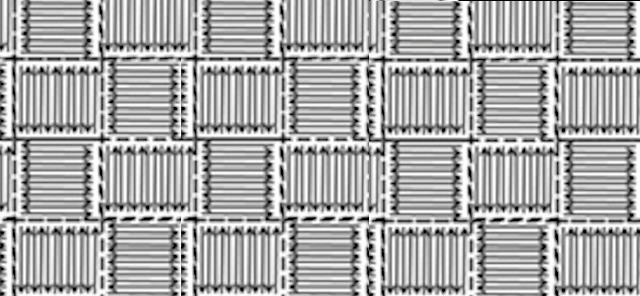

- Scan pattern simulation

- Distortion compensation

- Simulation-based support geometry

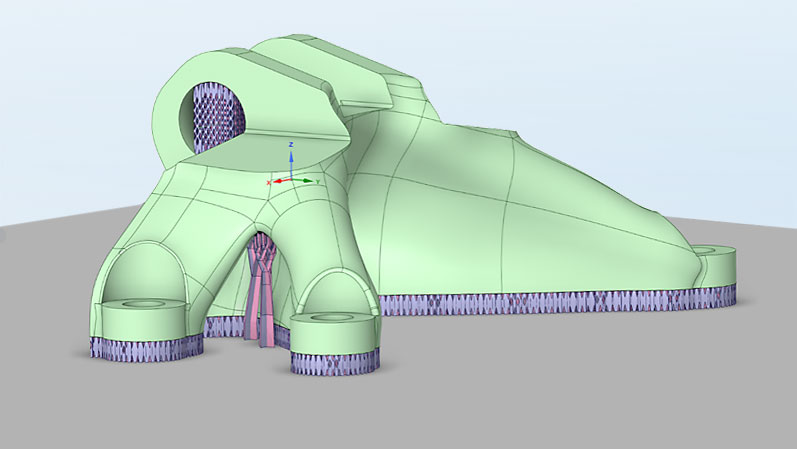

- Flexible support generation with SpaceClaim

- Prevention of blade crash

This software is part of the Ansys structural mechanics product family

Key facts and use cases of Ansys Additive Print

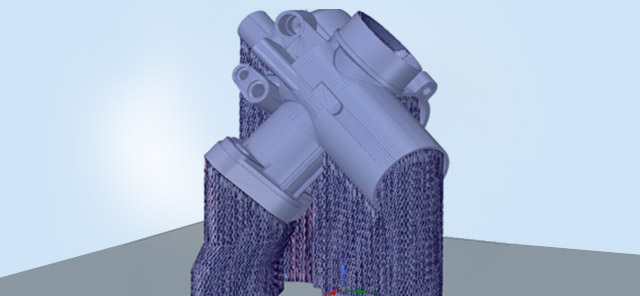

Support structures

Supports for stable component/build plate connection. The integration of support structures both creates a more stable connection between the component and build plate and dissipates more heat.

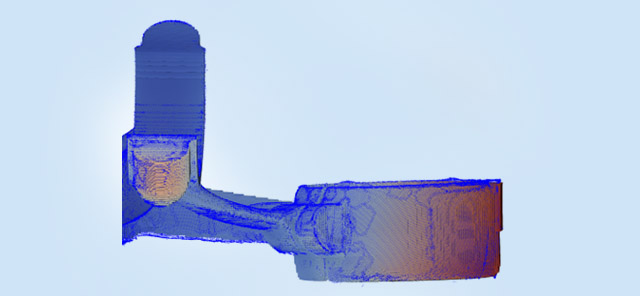

Warpage compensation

Precise components are created on the basis of compensated geometries. Component distortion caused by printing is automatically compensated for. To get precise components, a correspondingly compensated geometry is generated.

Scan Pattern

Simulation at scan pattern level provides more accurate results.

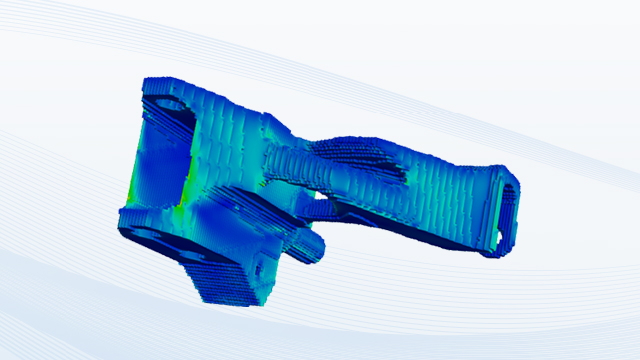

Preventing Blade Collisions

The early detection of critical points for blade collisions in the 3D printing systems is essential for production. Downtimes and high costs are avoided.

to of 2 matching news articles

CADFEM – Your Simulation Partner

With over 35 years of simulation experience, CADFEM is your ideal partner for all tasks from the wide-ranging world of structural mechanics.

For more information please contact us.

Training related to Ansys Additive Print

With over 30 years of experience in the field of further education and training, we teach the content that you – whether a beginner or an expert – need to simulate successfully with Ansys.

More Related Information

Get a deeper understanding of our solutions by taking advantage of our related offers.

The right solutions for your simulation projects

Simulation is everywhere and affects every industry. Since simulation requires more than software, CADFEM offers everything you need for successful simulation from a single source: software and IT solutions, consulting, support, engineering and knowledge sharing – always on the cutting edge.