CADFEM distributes the full Ansys portfolio of products and as an Ansys Elite Channel Partner, has a direct link to the globally leading simulation provider.

Ansys Software Suite: Engineering Simulation Software Products

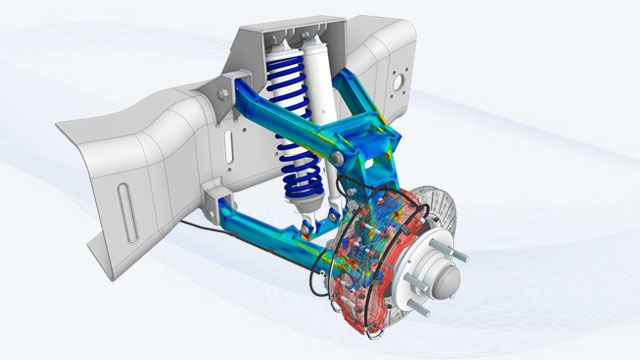

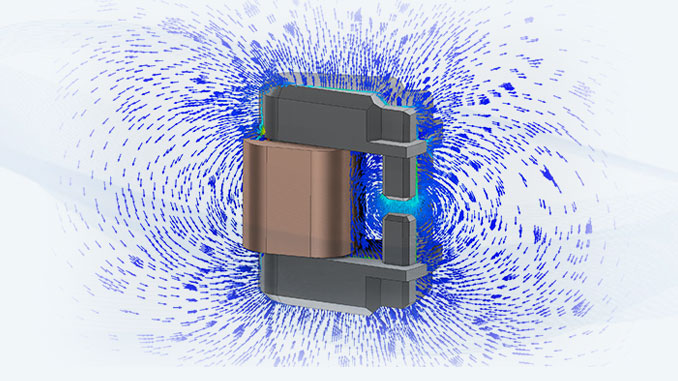

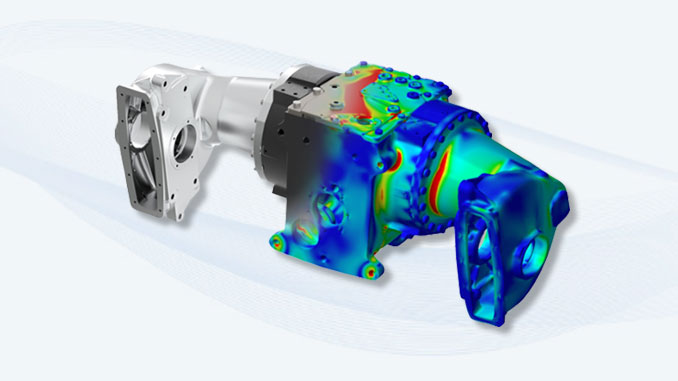

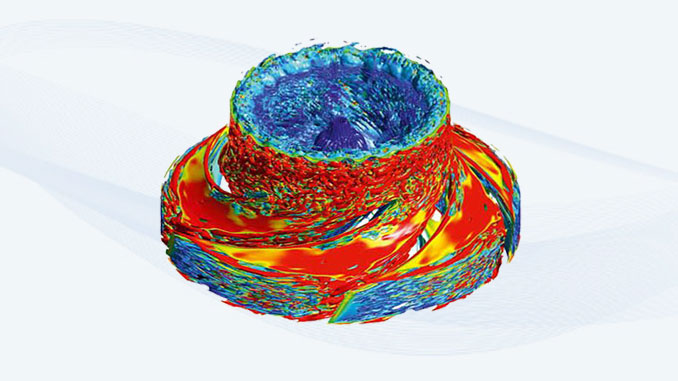

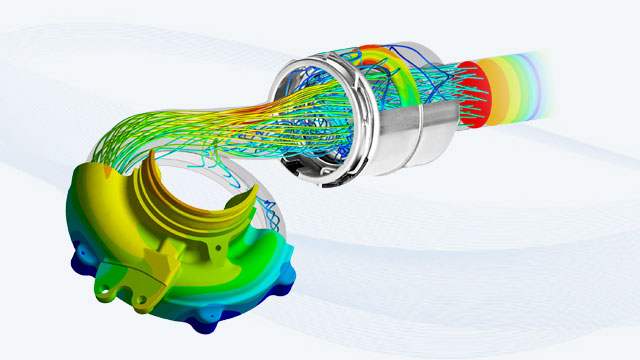

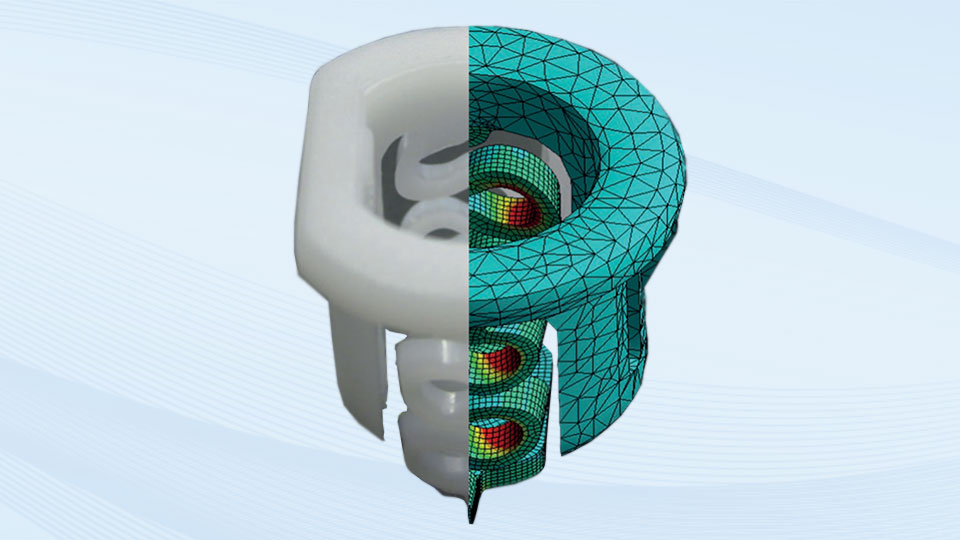

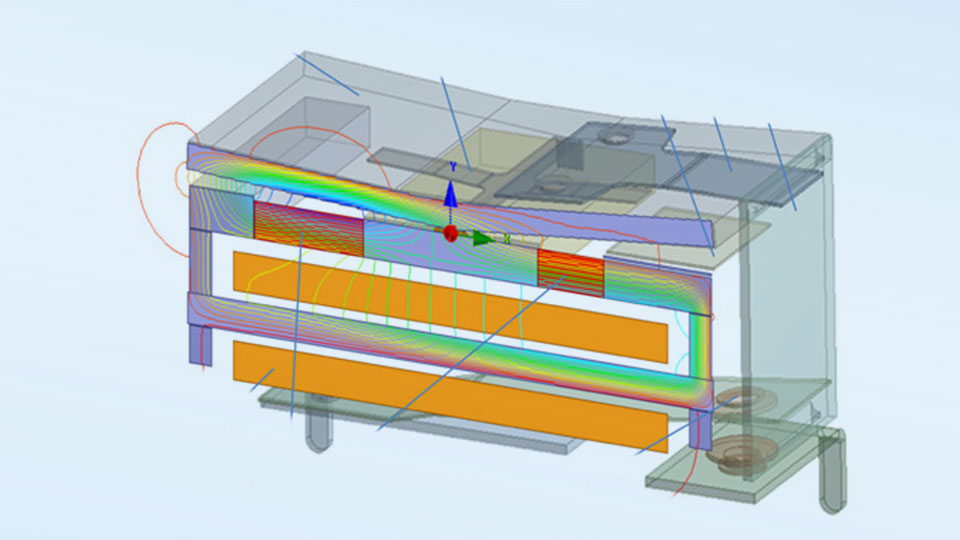

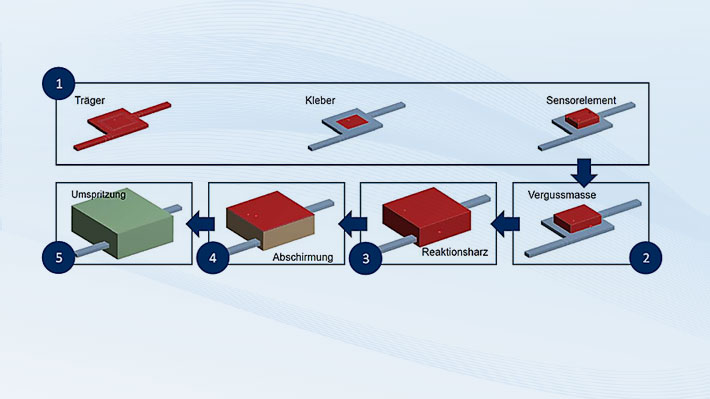

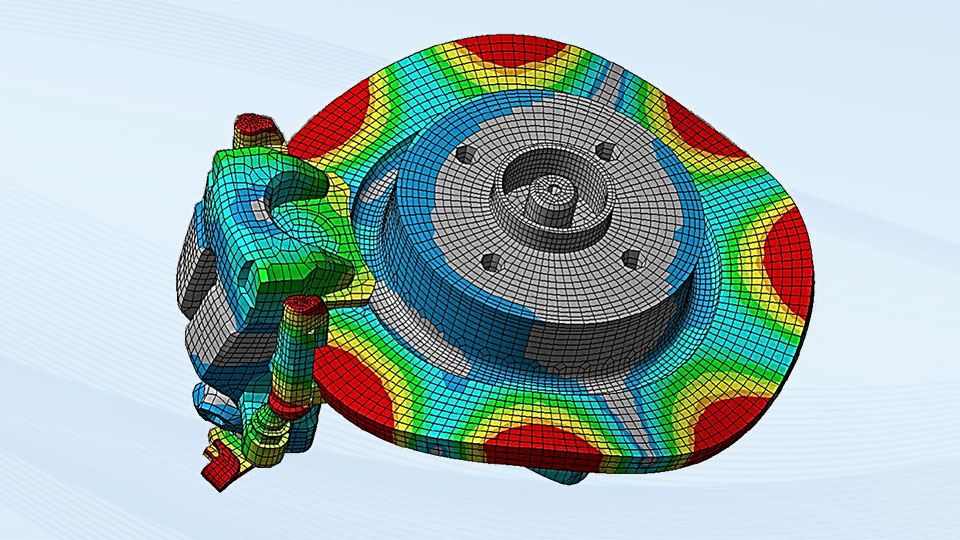

Ansys simulation software offers technologically leading solutions for virtually any simulation task. The functionality encompasses all work steps of CAE simulation based on Ansys technology platform. Ansys impresses users with powerful solver technologies for structural mechanics, fluid mechanics, electromagnetics, multiphysics and system simulation as well as multiphysics heat transfer simulations and optics.

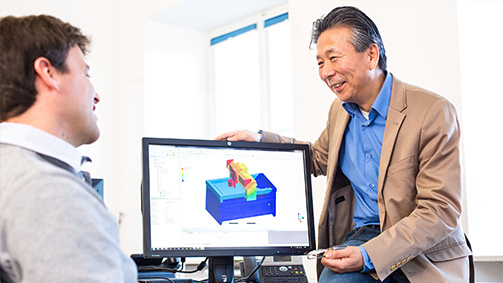

We are your specialists for software solutions in the simulation environment with more than 130 Ansys specialists. You can trust in our professionalism as an Ansys Elite Channel Partner.

Ansys Product Range

Discover the Ansys simulation software portfolio and get to know the technologically leading solutions for virtually any simulation task.

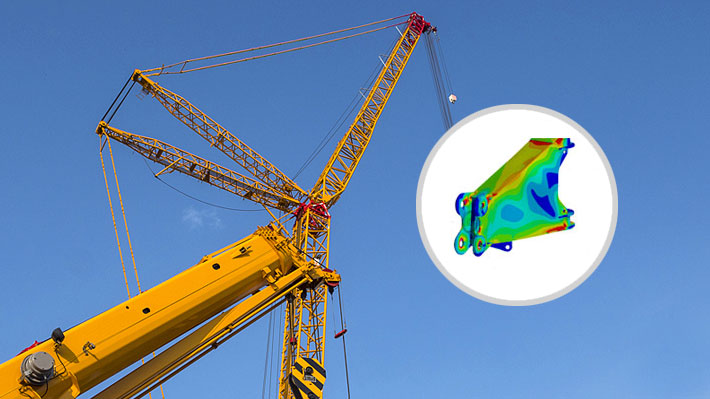

Ansys – used by market leaders and drivers of innovation across a wide range of industries

With products, service and expertise from a single source, our customers can make the most of their simulations – and often develop groundbreaking product and process innovations.

The right solutions for your simulation projects

Simulation is everywhere and affects every industry. Since simulation requires more than software, CADFEM offers everything you need for successful simulation from a single source: software and IT solutions, consulting, support, engineering and knowledge sharing – always on the cutting edge.