Simulation commissioned by the Institute for Occupational Safety and Health

Sector: Engineering firm/development service provider, HealthSpecialist field: Biomechanics, Structural mechanicsThe Institute for Occupational Safety and Health (the German IFA) provides support to the statutory accident insurance institutions in Germany when it comes to scientific and technical issues relating to occupational safety and health protection. In order to investigate a particular hazard scenario in kindergartens, they turned to CADFEM.

Summary

Task

Developing appropriate guidelines for the design of furniture edges usually requires a complex series of tests which then facilitate the determination of various load scenarios that would affect a child's head in the event of a fall that is followed by an impact on a given piece of furniture. It was envisaged that simulation would simplify this procedure.

Solution

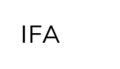

The simulation was based on real CT (computed tomography) scan data, which was transferred into a digital geometry model (STL) and then linked with Ansys ICEM so that numerical calculations could be performed. The impact simulations were performed within Ansys Workbench using the LS-DYNA ACT extension.

Customer benefits

The additional know-how gained was used to facilitate the design decision process and reduce R&D costs. As a result, the actual test time inside the wind tunnel facility was reduced to only half a day.

Project Details

Task

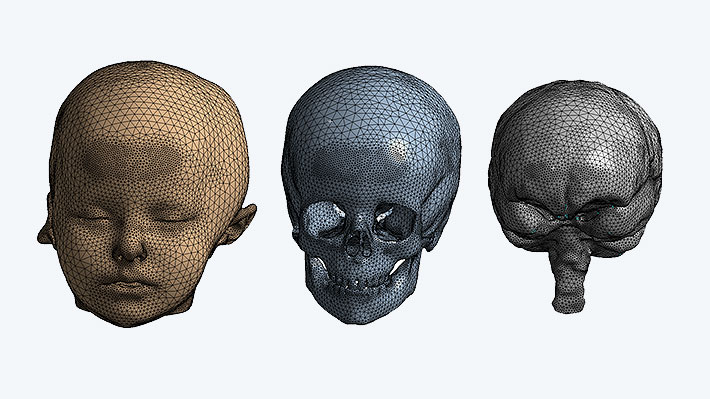

The Institute for Occupational Safety and Health (IFA) provides support to the statutory accident insurance institutions in Germany when it comes to scientific and technical issues relating to occupational safety and health protection. Developing appropriate guidelines for the design of furniture edges usually requires a complex series of tests which facilitate the determination of various load scenarios that would affect a child's head in the event of a fall that is followed by an impact on a given piece of furniture. Naturally, human experiments are out of the question, so the IFA has been investigating new ways of dealing with this that would make it possible for them to issue reliable statements concerning the damage in view. In collaboration with CADFEM, a simulation model was created for the purpose of answering this very question.

Customer Benefit

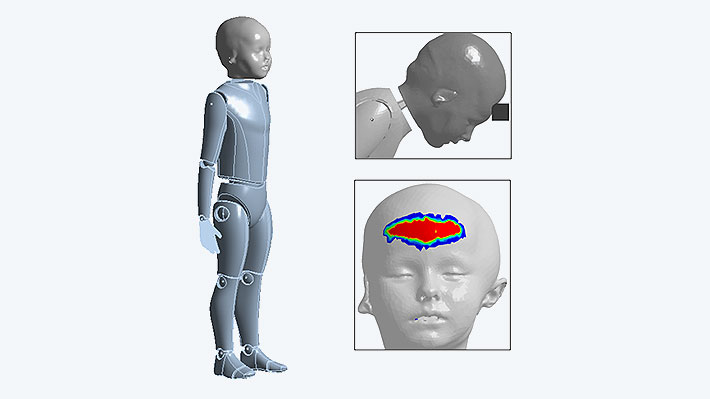

Since impact tests are, for ethical reasons, not feasible, the corresponding investigations must be carried out using dummies or virtual models. Numerical simulation has enormous advantages over costly series of dummy-based tests – which, in any case, only ever produce very limited results. Once a simulation model has been created, a broad variety of camber-based variants can be simulated, automatically evaluated, and then compared with each other within a short space of time. When it comes to dummy tests, it is necessary that the point at which particular data (relating to, for example, forces or acceleration) is to be measured and evaluated be precisely defined for any given test. When it comes to simulations, on the other hand, all the data contained within the entire body model remains available at all times. Furthermore, CT scan data can be used to create realistic models of the head – which then also provides data from within the inside of the skull.

Courtesy of Institute for Occupational Safety and Health

Solution

The simulation was based on real CT (computed tomography) scan data, which was transferred into a digital geometry model (STL) and then linked with Ansys ICEM so that numerical calculations could be performed. The impact simulations were performed within Ansys Workbench using the LS-DYNA ACT Extension. Following creation of the simulation model and development of a corresponding workflow, those involved were able to calculate and evaluate different impact scenarios by altering a variety parameters. A variety of impact points – such as the forehead and the cheek – were allowed for, and impact velocities and edge radii were subjected to modifications.

Images: © Institute for Occupational Safety and Health (IFA)