Simulation commissioned by agtatec AG

Sector: Machinery and plant engineeringSpecialist field: Fluid mechanicsAgtatec record ag is one of the world leaders in automatic door systems. Innovative, intelligent door systems of the future will need to be able to operate under different wind load scenarios on a fully automated basis. CADFEM and Ansys are assisting with their design, through the use of simulation.

Summary

Task

Using computational fluid dynamics (CFD) to investigate a variety of virtual door prototypes under numerous different load scenarios and thus reducing the actual testing time in wind tunnel facilities.

Solution

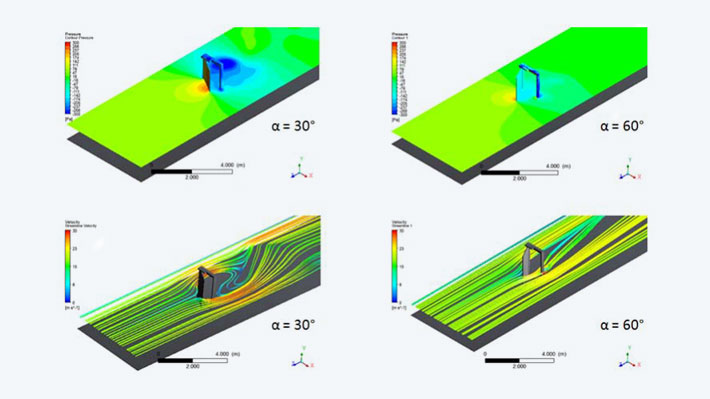

A variety of door applications underwent investigation using Ansys Workbench within a virtual wind tunnel environment. Parameters such as wind speed, door opening angle, and shape were defined as input variables.

Customer benefits

The additional know-how gained has been used to facilitate the design decision process and reduce R&D costs. As a result, actual testing time within the wind tunnel facility was reduced to only half a day.

Project Details

Task

Agtatec record AG is one of the world leaders in automatic door systems. Innovative, intelligent door systems of the future will need to be able to operate under different wind load scenarios on a fully automated basis. Hence, the underlying powertrain needs to be able to guarantee precise opening behavior for different door shapes, opening angles, and varying aerodynamic load scenarios. Traditionally, aerodynamic force data is gathered during cost-intensive wind tunnel measurement cycles. Computational fluid dynamics (CFD) represents a simulation approach that can drastically decrease product development costs by allowing investigation of a variety of load scenarios on different virtual door prototypes, thus reducing actual testing time in wind tunnel facilities.

Customer Benefit

Wind tunnel tests tend to drastically increase product development costs, especially in cases where a variety of parameters need to be investigated. With the aid of of numerical fluid simulations, the following goals were achieved:

- The sensitivity of parameters such as door shape, wing opening angle, and aerodynamic load was investigated at an early development phase.

- The additional know-how was used to facilitate the design decision process and reduce R&D costs. As a result, the actual testing time within the wind tunnel facility was reduced to only half a day.

- The derived simulation model represents a validated framework that can be used in the development of future innovative door prototypes within a virtual environment.

Courtesy of Agtatec record AG

Solution

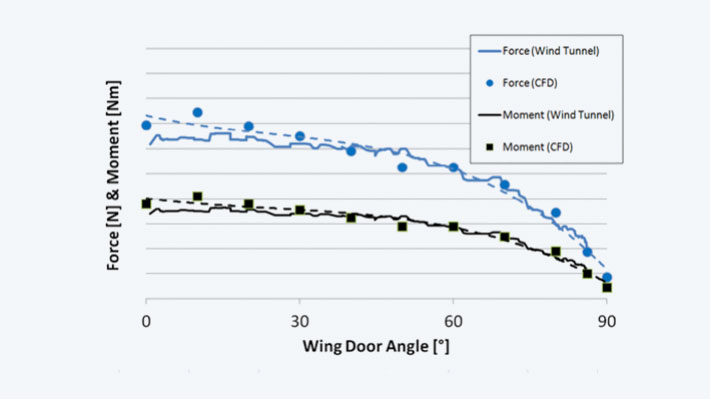

A variety of door applications underwent investigation within a virtual wind tunnel environment. Parameters such as wind speed, door opening angle, and shape were defined as input variables. Fully automated simulation loops were conducted using Design Point Manager within Ansys Workbench, leading to the derivation of the wind load matrix. In order validate the virtual prototype, consecutive experiments were conducted in the Sauber Engineering wind tunnel facility in Hinwil. Comparison of the aerodynamic loads revealed by the experimental and the numerical setups shows a high degree of consistency, thereby validating the proposed simulation framework .

Images: © agtatec record