Virtual paint simulation

Sector: Automotive (motor vehicles/trucks)Specialist field: Structural mechanics, Heat TransferAudi AG uses virtual paint simulation to simulate the paint drying behavior of car bodies for the optimal design of drying ovens.

Summary

Task

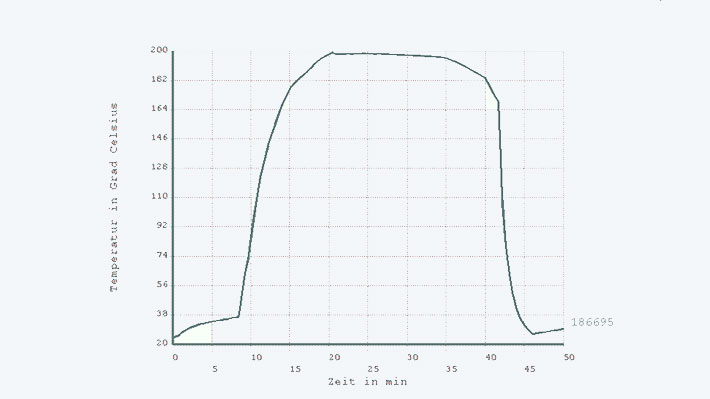

In paint drying, it must be ensured that the quality criteria are met for each individual vehicle type that passes through the drying oven. These are characterized by the optimum temperature-time windows for paint and adhesive curing and bake hardening. The thermal distortion of the individual components of the vehicle bodies during paint drying is also of interest.

Solution

The otherwise very complex and time-consuming drying simulation of complete vehicle bodies is solved efficiently and within short response times with virtual paint simulation . This is achieved by special algorithms that take into account the shape, position, and temperature of the entire body surface.

Customer benefits

Virtual paint simulation enables early evaluation of the design suitable for painting during body development. Process optimization in production is carried out extremely efficiently with virtual models.

Project Details

Task

Cathodic dip painting (CDP) is an electrochemical painting process used in the automotive industry. After painting, the paint must be cured in a drying oven. This curing is often combined with a heat treatment of the car body sheets. Virtual paint simulation processes steps of vehicle painting, e.g., the simulation of paint drying using the virtual paint simulation /DRY module. Here, it must be ensured that the quality criteria are met for each individual vehicle type that passes through the drying oven. These are characterized by the optimal temperature-time windows for paint and adhesive curing and bake hardening. Furthermore, the thermal distortion of the individual components of the vehicle bodies during paint drying is of interest.

Customer Benefit

Virtual paint simulation enables the early evaluation of the paintwork-compatible design during body development. Process optimization in production is carried out extremely efficiently with virtual models.

Solution

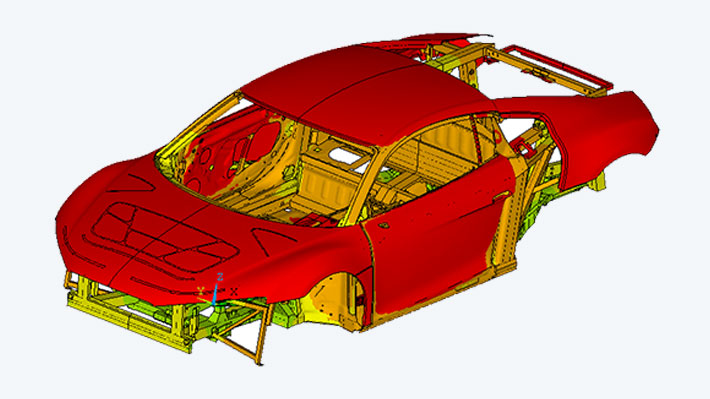

The simulation model for virtual paint simulation /DRY consists of a vehicle model and a furnace model. The vehicle model is generally taken from an existing vehicle model, e.g., a crash model. The furnace is described by zones that differ in equipment and temperature. Equipment features are, for example, nozzles, heated furnace walls, or fans. Both convection and radiation are considered. Complete vehicle bodies with all interior sheets are very complex structures for this simulation task. The complete modelling and direct solution of all physical phenomena involved, including the corresponding boundary conditions, would therefore lead to disproportionately high costs in terms of model generation and simulation time. With virtual paint simulation /DRY this task can be solved economically and within short response times. This is achieved by special algorithms that take into account the shape, position, and temperature of the entire body surface.

Images: © Audi AG