Transport solutions from Schwarzmüller: Less weight. More capacity.

Efficiently from A to B

According to the Federal Statistical Office, in 2021 more than 5 million trucks in Germany alone will have transported goods with a total weight of more than 3.1 billion tons. Because energy consumption is to be reduced despite growing volumes, products and processes must become more efficient. The Schwarzmüller Group, a leading supplier of towed commercial vehicles in Europe, is doing this by systematically minimizing the dead load of its transport solutions. Simulations with Ansys play a key role.

Anyone who regularly travels on the highway inevitably encounters Schwarzmüller products. The logo of Europe's largest niche supplier of trailers and bodies is omnipresent in freight transport. This is because the specialist for individual transport solutions from Austria supplies the construction industry, the raw materials and recyclables industry as well as transport, logistics and infrastructure companies in 21 countries.

The product range comprises around 150 products. The claim "built entirely on excellent vehicle technology" is the added value that customers feel when plateau, tipping, tank, container transport and other special vehicle solutions from Schwarzmüller are used. High availability, individuality and innovation are success factors in a market that is more dynamic than many initially assume. For example, customers - and not just since energy prices started skyrocketing - are placing great value on ever lighter, more energy-efficient products. After all, every kilo saved means lower costs.

Simulation as a development tool: Make or buy?

Lightweight design has been a long-running topic for Schwarzmüller's development engineers. Strategies for weight reduction range from material selection and minor design modifications to thinking of completely new, innovative approaches. For trend statements on feasibility, CAD-related, design-accompanying calculations are also common.

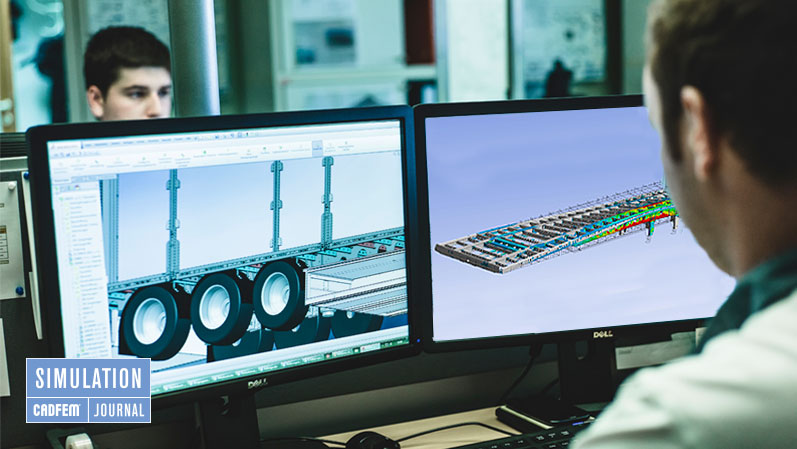

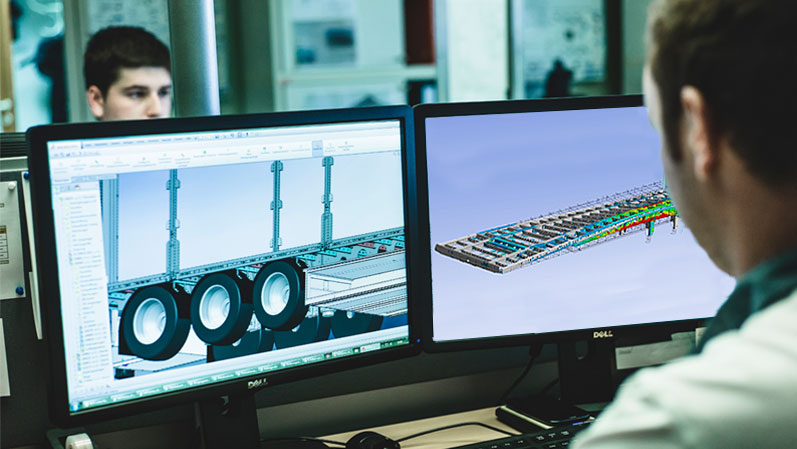

For the precise solution of complex physical problems, though, Schwarzmüller relies on detailed simulations by specialists. Such tasks were outsourced to external service providers until 2021. The decision to implement them in-house matured as demand increased. Less handling effort, shorter waiting times, more independence are just a few of many reasons for an in-house simulation solution.

Less handling effort, shorter waiting times, more independence are just a few of many reasons for an in-house simulation solution.

Together with CADFEM (Austria) GmbH, a concept tailored to Schwarzmüller's individual requirements was developed. In addition to simulation-based topology optimizations for weight reduction of the support structures, vibration analyses turned out to be a topic with a need for action.

These and other tasks are meanwhile processed within the company's own small calculation team using Ansys simulation tools. "With Ansys Workbench, various analysis methods can be applied from a central platform," summarizes Harald Bruhns, Head of Digital/Orga at Schwarzmüller, regarding the new independence in professional simulation.

In addition to the cost advantages, the development team benefits from the short time-saving paths and the better understanding of the physics in their own products. Those who do the calculations themselves gain much deeper insights than those who "only" have to deal with the results. Optimization potentials are thus identified even faster and more precisely, ideas for new and further developments can be compared objectively in a short time without having to build real prototypes.

Less is more: topology optimization

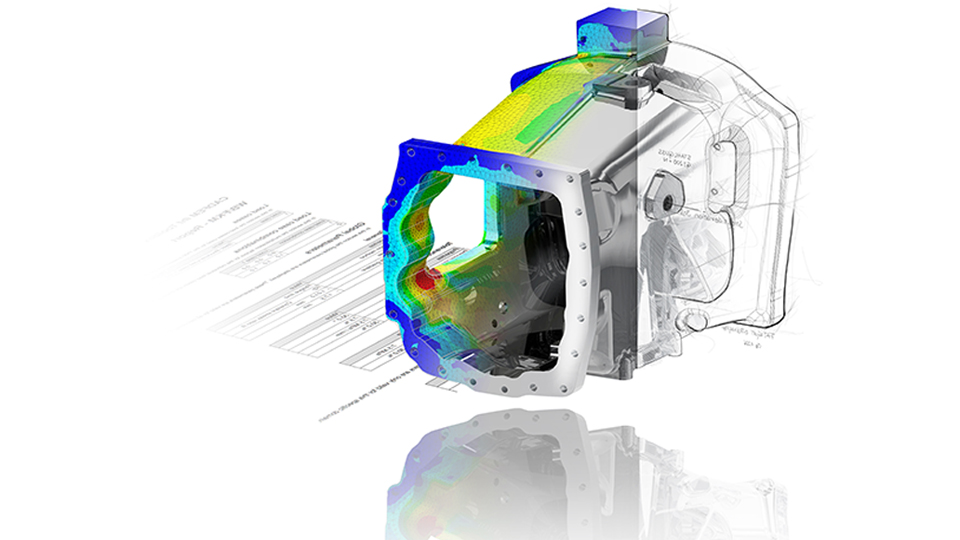

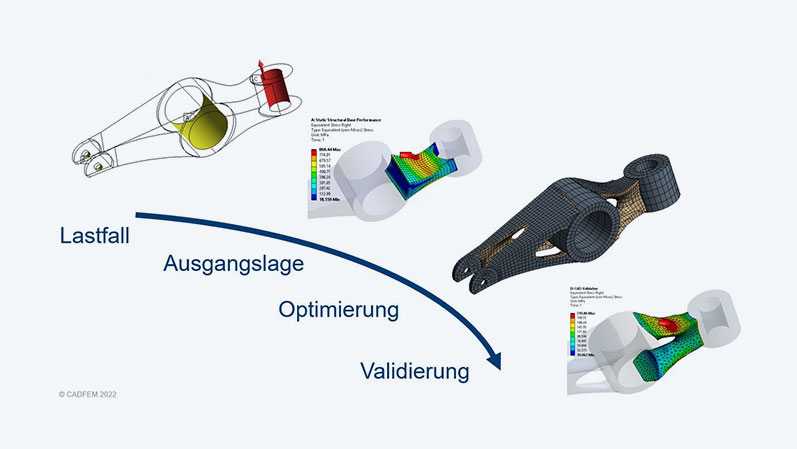

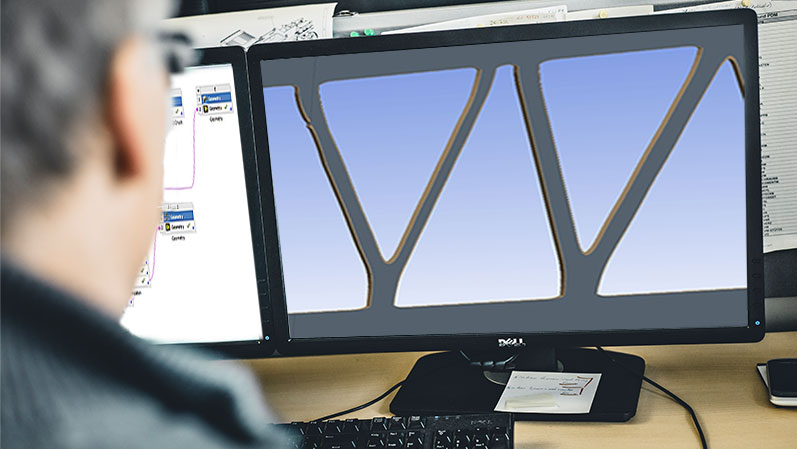

In topology optimization, a component is analyzed for the optimum structure by identifying the relevant load paths. For this purpose, Ansys determines the efficient material distribution within the defined design space. In addition to the relevant mechanical loads, important design or manufacturing-related specifications are also included. "Topology optimization is a very good example of how the understanding of our assemblies is improved. With the information generated from this, we can derive optimal concepts in an even more targeted manner," confirms Harald Bruhns.

Until now, weight reductions have been repeatedly achieved at Schwarzmüller in various ways, which had to be validated by extensive real-world tests. With systematic topology optimization, further significant savings in individual assemblies of around 20% are possible with less effort, which is also noticeable in lower material costs.

Schwarzmüller products are analyzed in detail for such savings potentials which - very importantly - do not affect either safety or functionality. Often, the well-founded simulations with Ansys not only lead to lighter, resource-saving solutions, but even contribute to increases in performance and an increase in transport capacity. More performance. Less weight.

There is power in tranquility: reducing vibrations

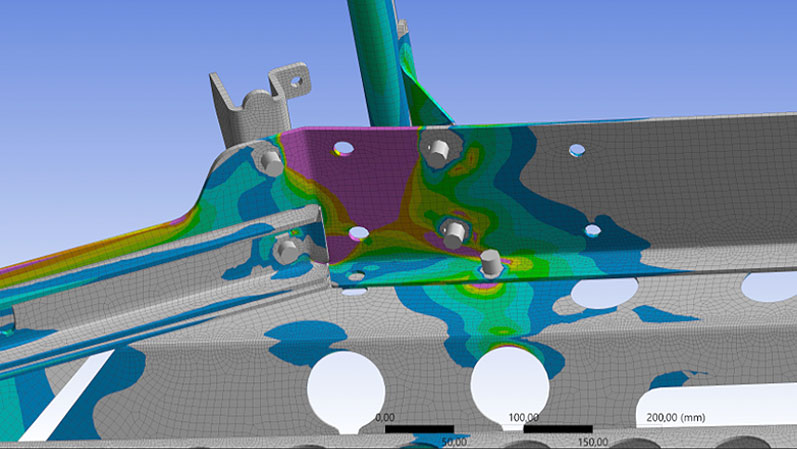

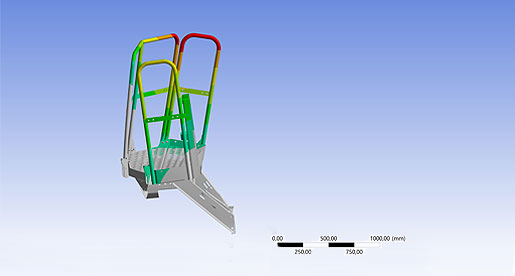

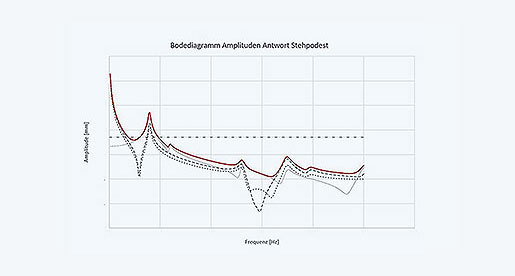

Quality in trailers and vehicle bodies also means that they absorb vibrations during transport and keep them away from the cargo. Vibrations caused by uneven road surfaces or strongly swinging tractor units can damage the transported goods. They can also generate disturbing noise for the environment.

With structural dynamic simulations in Ansys Mechanical, such effects, or their origin, are simulated and analyzed, and countermeasures are derived from the results. Simulation enables the Schwarzmüller technical team to prevent undesirable vibrations in advance in a targeted manner with considerably less effort and a higher, objective understanding of the details. The result is literally "noticeable" for customers compared to many other products whose damping is based on the traditional and industry-standard approach of a purely experimental testing of the driving process.

On the road with CADFEM

When it comes to simulations with Ansys, CADFEM (Austria) GmbH is Schwarzmüller's partner. The cooperation began even before the introduction and has long since become a trusting and close exchange at eye level – from the training and further education of the users (which at Schwarzmüller takes place primarily via the CADFEM eLearning formats, which can be used very flexibly) to acute problem solving by user support to advice on all aspects of the future expansion of the Ansys infrastructure.

Harald Bruhns, Head of Digital/Orga, SchwarzmüllerThe eLearning modules offered by CADFEM allow us very flexible and timely training.

One thing is certain: the range of applications for detailed simulation at Schwarzmüller will be expanded in the near future following the successes already visible at an early stage in the areas of application described. A first step will be the establishment of a dedicated calculation department, which will also deal with the virtual analysis and optimization of issues relating to operational strength and weld seam evaluations. Further ideas and plans are already underway and will be quickly brought to the table during the next discussions with CADFEM. Because the name Schwarzmüller not only stands for efficiency in products, but also in processes.

Wilhelm Schwarzmüller GmbH

Harald Bruhns

Author: Alexander Kunz, CADFEM Germany GmbH

Images: © Wilhelm Schwarzmüller GmbH

Published: January, 2023

Contact CADFEM