Simulation commissioned by Bär Cargolift

Sector: Automotive (motor vehicles/trucks)Specialist field: Structural mechanicsBesides maximum performance, high safety and robustness are the basis for the long-term successful use of Bär Cargolift tail lifts.

Summary

Task

To ensure the performance of the components, non-linear calculations of different variants of tail lifts were performed.

Solution

Setup of a simulation workflow for the geometrical and material nonlinear calculations with Ansys Mechanical consisting of three steps.

Customer benefits

With the virtual models, it was possible to select the most suitable designs without great effort and without real prototypes in a manageable time.

Project Details

Task

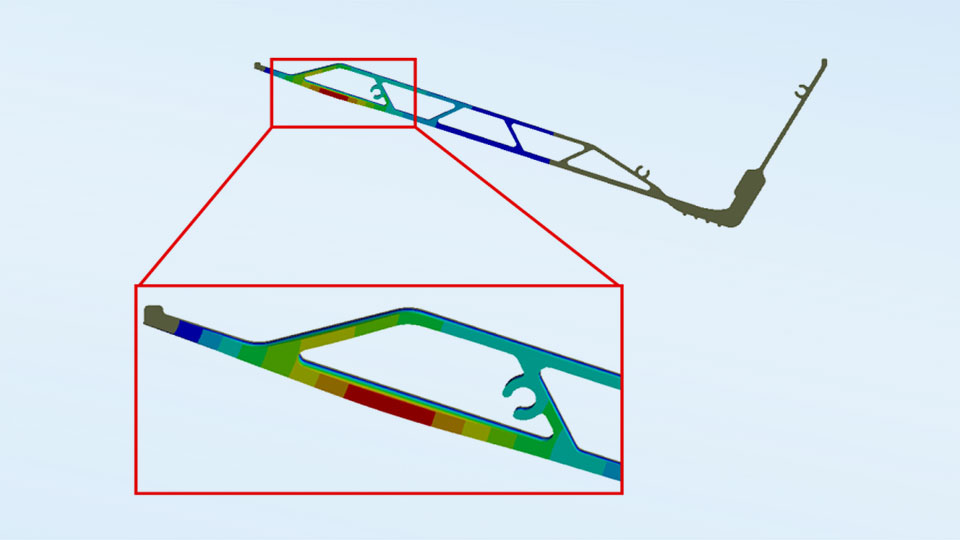

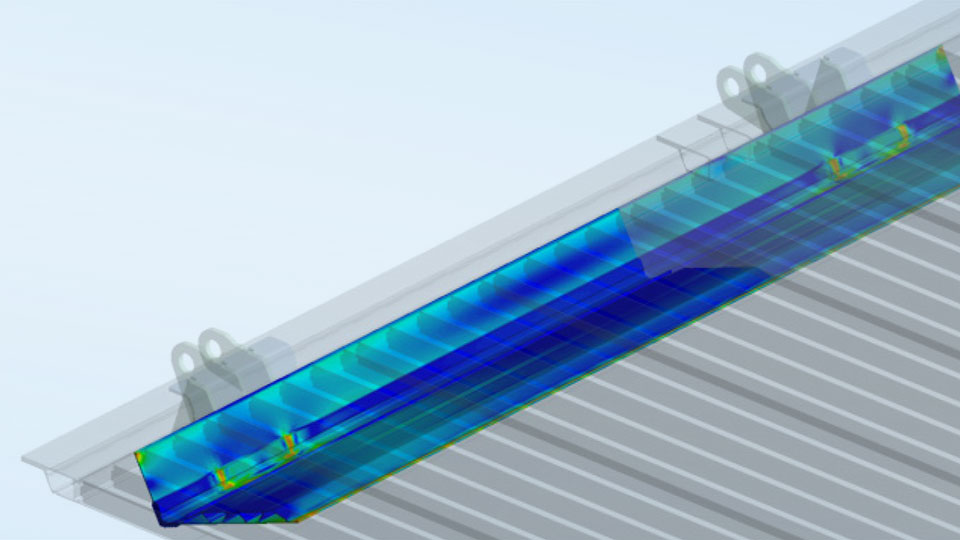

Besides maximum performance, high safety and robustness are the basis for the long-term successful use of Bär Cargolift tail lifts. In order to keep the weight of the tail lift low and thus reduce fuel consumption and increase the loading capacity, lightweight components are often used. In order to secure the performance of these components non-linear calculations of the tail lift were carried out, where up to three times the required moment load was applied. In order to be able to make a comparative analysis, several platforms with similar topology but different substructures were investigated!

Customer Benefit

Since the stability testing of different designs and substructure profiles was carried out with virtual models and without real prototypes, the selection of the appropriate constructions were made without great effort and in a manageable time. In addition to a significant reduction of the development time, additional cost savings in extrusion tools were achieved. Now, since only one tool is required for the selection of a safe design with the help of simulation, expensively manufactured real prototypes for testing can be largely eliminated.

Solution

The simulation workflow for the geometric and material nonlinear calculations with Ansys Mechanical consisted of three steps:

- a linear static analysis to generate the prestress in the system

- a prestressed linear buckling analysis to study the global buckling behavior and identify a critical buckling shape.

- a nonlinear static analysis with local imperfection, i.e. pre-damage due to buckling. Volume components were meshed with volume elements with quadratic displacement formulations. In the case of surface components such as the loading area, an idealization as a mid-surface model and meshing with shell elements was performed. With Ansys loading areas with nominal loads of 1500 kg and 2000 kg with different substructure profile geometries with two and five chambers were analyzed and their suitability for practical use was investigated.

Images: © Bär Cargolift