High component quality through 3D print simulation in Additive Manufacturing. From topology optimization to process simulation.

Simulation software for 3D printing and Additive Manufacturing

Ansys software supports you in the production of high-quality AM components. Optimize your process parameters to minimize distortion effects and achieve an ideal design.

Improved AM manufacturing processes and design

Explore and evaluate the various possibilities of the AM manufacturing processes by using simulation. Identify the critical points of components and, thus, avoid waste by early adjustments to the component design or the printing process.

Introduction to 3D printing

In recent years, 3D printing has been discovered by the industry and has become a real area of interest. Additive components are not only used in the automotive and aerospace industries; small and medium-sized companies are also increasingly relying on additive manufacturing. The advantage is obvious: prototypes as well as production parts can be manufactured within a very short time - usually within a few days - without the manufacturing of expensive moulds. The integration of many functions into one component or the combination of entire assemblies into one additive part can also save a lot of time and money during the entire process chain.

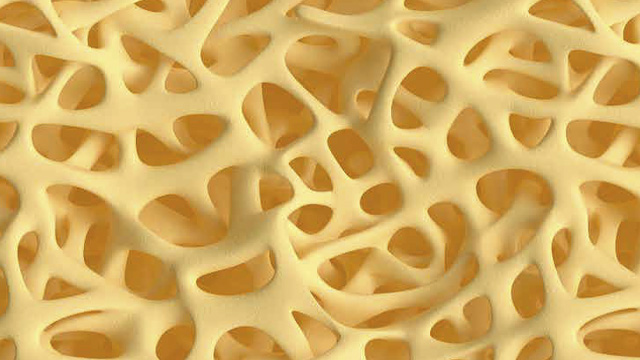

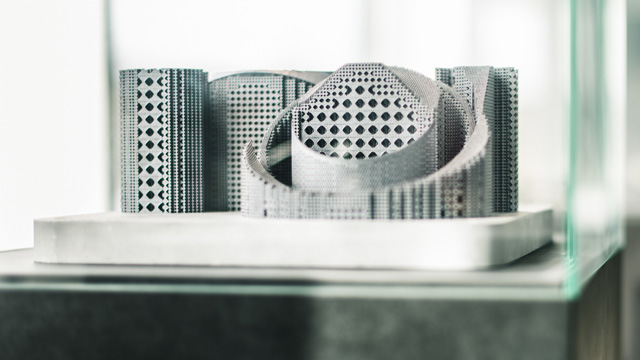

Metal 3D printing is a manufacturing method of components mainly made of powder by adding layers of tiny welding tracks (hatches). With this method, geometries can be created that are impossible to be produced conventionally or only at great expense.

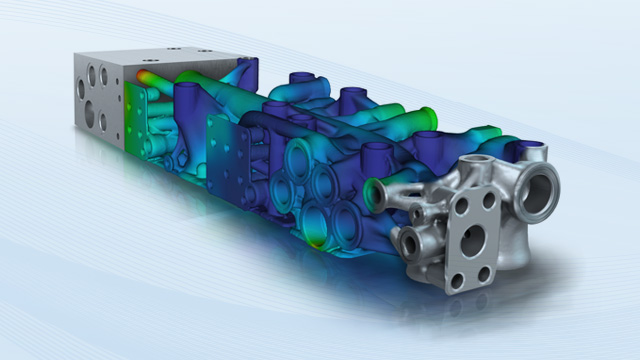

Simulation for Additive Manufacturing

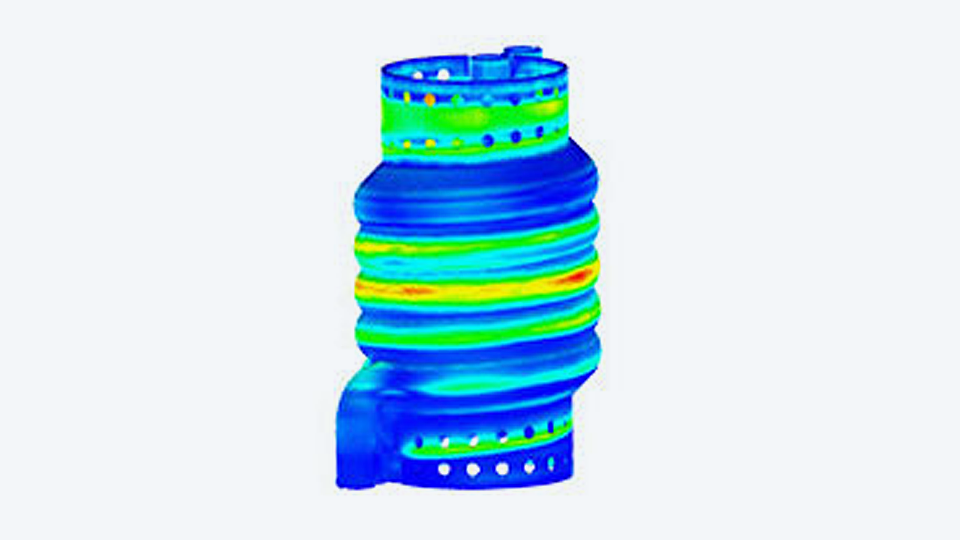

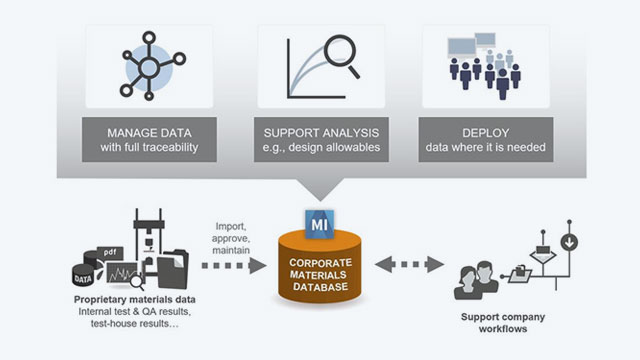

An important factor for cost-efficient additive manufacturing is the use of simulation software. Since incorrect prints can quickly become critical for any budget because of expensive machine running times, it makes sense to use simulations during product development to identify the critical points of the component regarding the printing process. Waste can be avoided by early adjustments to the component design or the printing process. With its simulation tools, Ansys offers the user support in optimizing the Design for Additive Manufacturing (DfAM) and ensures reduced development and production costs.

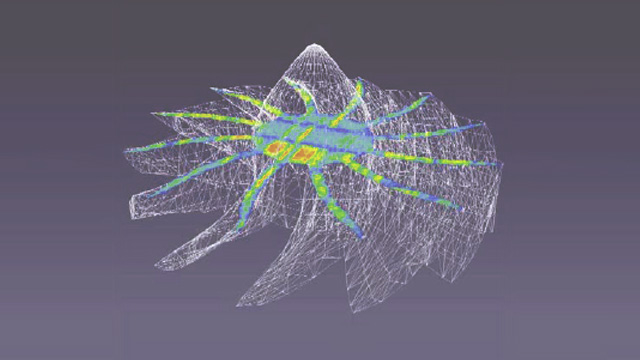

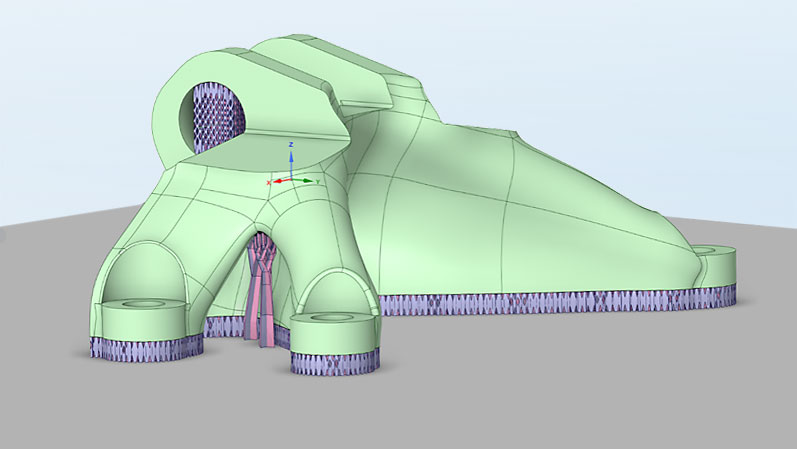

Topology optimization

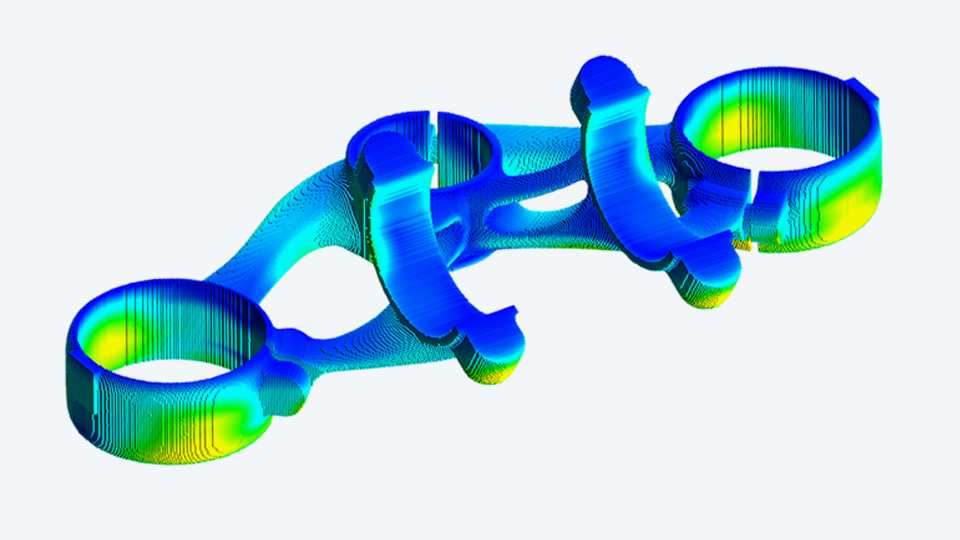

With topology optimization the shape of a component can be optimized considering its mechanical properties.

Benefits

For example, it becomes possible to design lighter components without losing stiffness. Topology-optimized lightweight components are often used in aerospace, automotive and other areas of mechanical engineering. Ansys' topology optimization offers fast calculations, a high selection of possible boundary conditions as well as surfaces that require only a minimum of post-processing.

How to manufacture a topology optimized metal component?

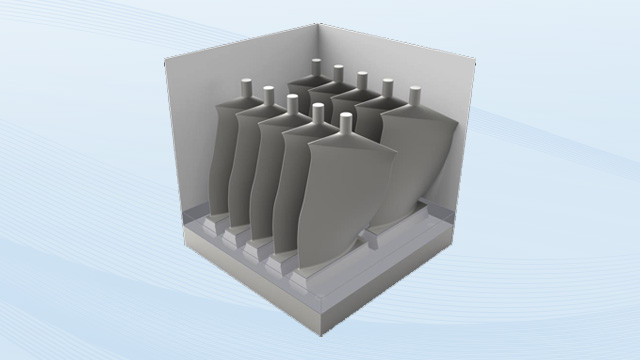

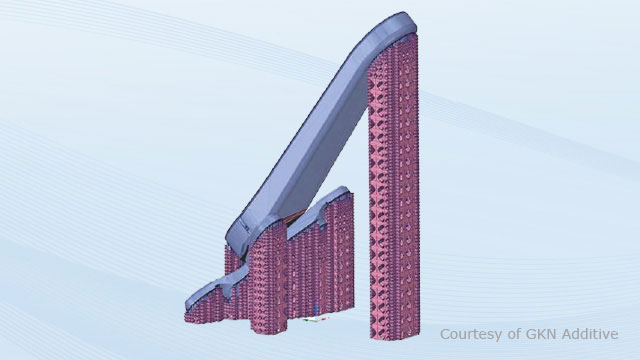

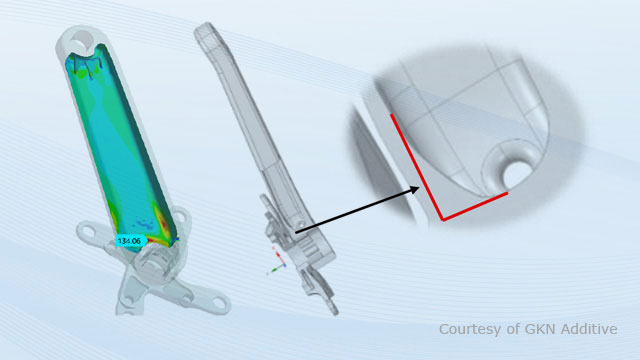

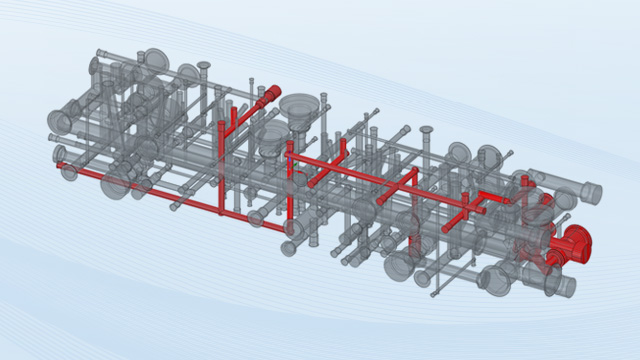

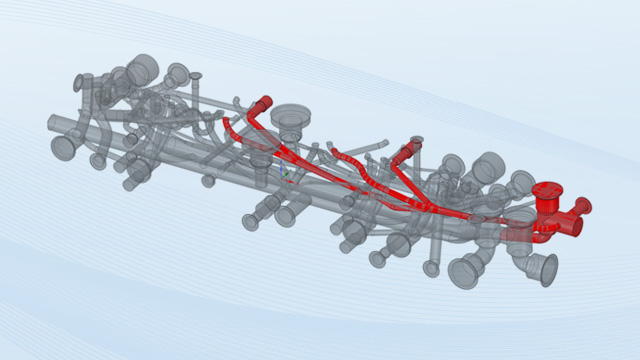

For high component quality, it is necessary to carry out several steps carefully in data preparation. It starts with the optimal component position in the 3D printer, followed by the attachment of support structures required in metal 3D printing, and, finally, the simulation of the print job in order to avoid sources of error such as extensive stresses, distortion or coating collisions. Finally, the 3D data can be exported into a 2D layer data format.

- Orientation

- Support structures

- Distortion (incl. Predistortion)

- Stress

- Export into layer data format

How do I determine the optimal process parameters for metal 3D printing?

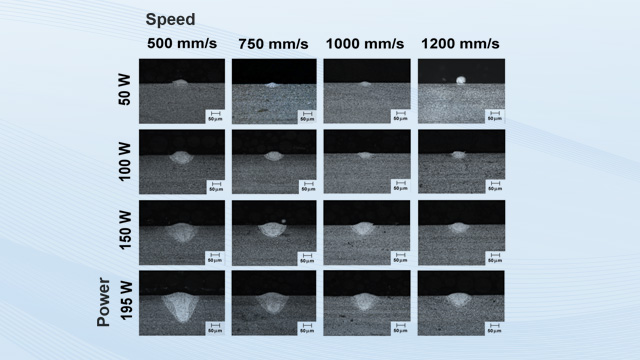

Process parameters precisely matched to additive materials are the key to ideal 3D printing. Only the right combination of laser power, laser speed and hatch distance guarantees success. With simulation software from Ansys, expensive investigations with prototypes can be minimized. Methods such as single bead, porosity, thermal history and microstructure prediction are used to determine optimal parameter combinations in advance.

CADFEM – Your Simulation Partner

With over 35 years of simulation experience, CADFEM is your ideal partner for all tasks from the wide-ranging world of structural mechanics.

For more information please contact us.

Dr. sc. ETH Manfred Maurer

Products for AM Simulation

CADFEM training on the subject of Additive Manufacturing

Learn in compact training how to develop approaches for an optimal "Design for Additive Manufacturing" (DfAM) considering all process issues, such as component orientation, support strategy, preparation for production and thermal distortion.

More Related Information

Get a deeper understanding of our solutions by taking advantage of our related offers.

The right solutions for your simulation projects

Simulation is everywhere and affects every industry. Since simulation requires more than software, CADFEM offers everything you need for successful simulation from a single source: software and IT solutions, consulting, support, engineering and knowledge sharing – always on the cutting edge.