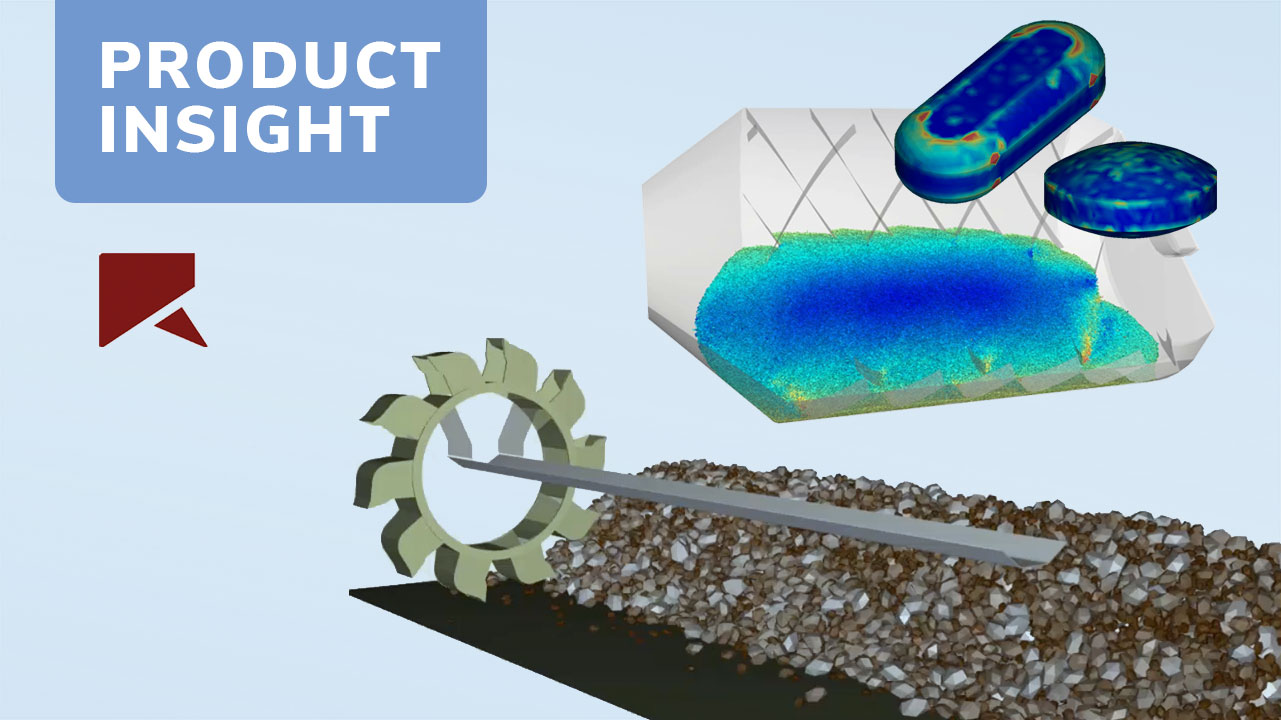

The discrete element method (DEM) provides decisive answers for bulk material handling.

Discrete element method – separating the wheat from the chaff!

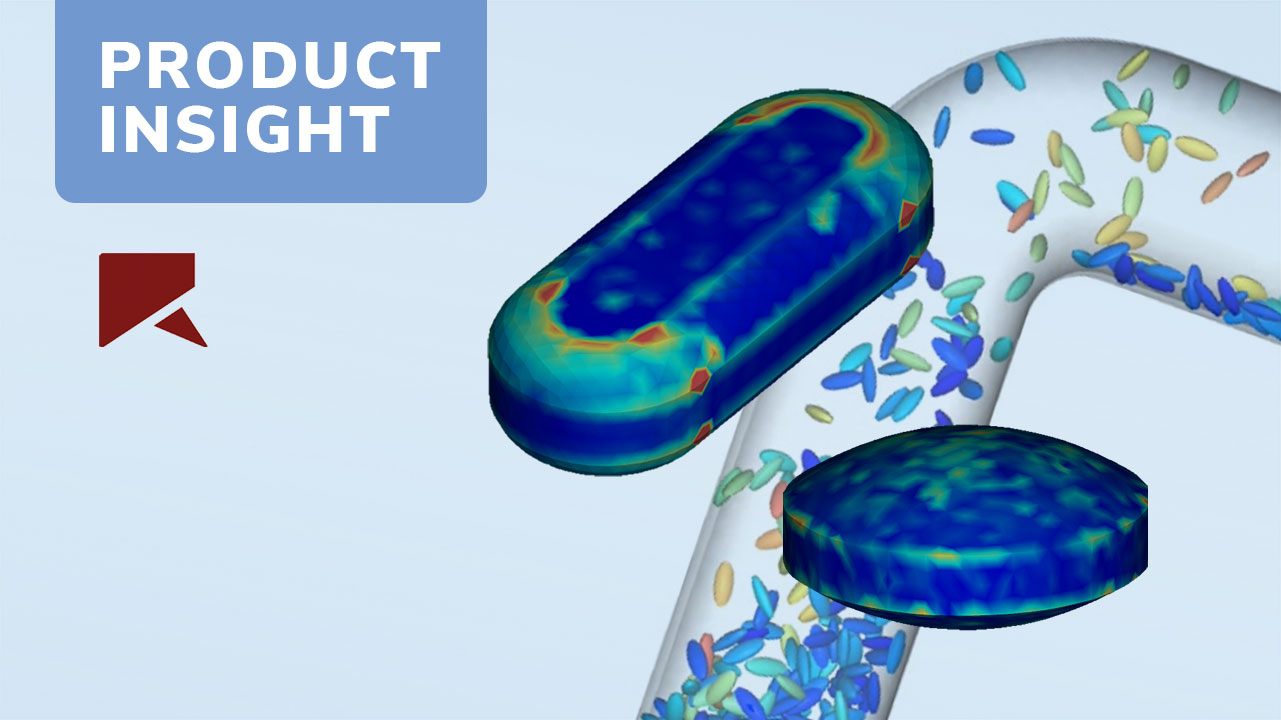

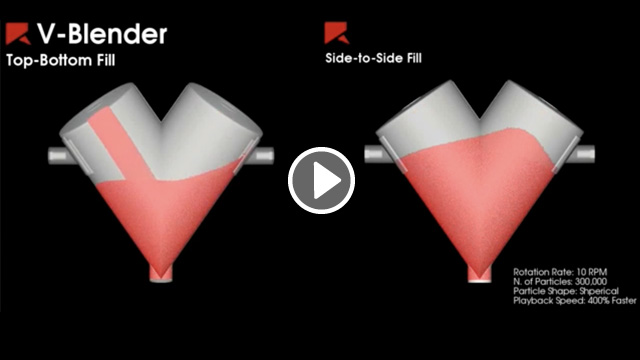

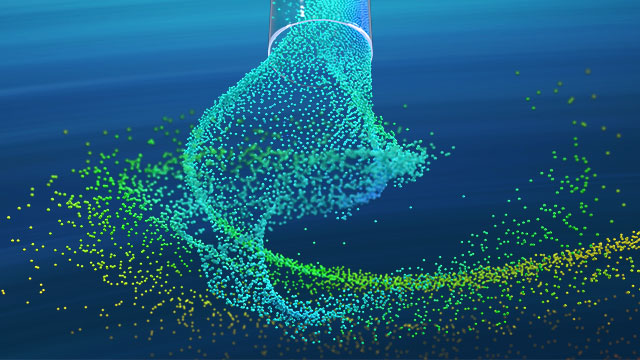

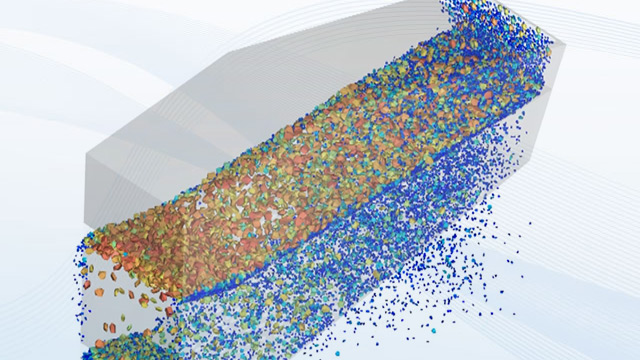

Simulation drives innovation in process engineering. Equipment and processes can be optimized using particle simulation based on the discrete element method (DEM). The freedom to choose any solid and particle shapes and the use of GPU hardware technology open up completely new possibilities.

Wide range of application options

DEM helps wherever particles, solids or entire components are moved and processed in mechanical process engineering.

Reap the benefits

When designing machines and equipment, engineers benefit decisively from being able to accurately predict the behavior of solids (particles) in process engineering. Shorter development cycles, affordable designs, long machine running times, lower maintenance costs, better product quality and, ultimately, happier customers are just some of the positives. Competitiveness is also boosted, while illustrative presentations make it easier to communicate project results. Systematically expand your expertise with realistic and advanced simulations.

Latest technology in DEM simulation with Rocky

The closeness to reality and computational speed are crucial to the successful use of particle simulation software. ROCKY DEM is setting a new standard in this regard.

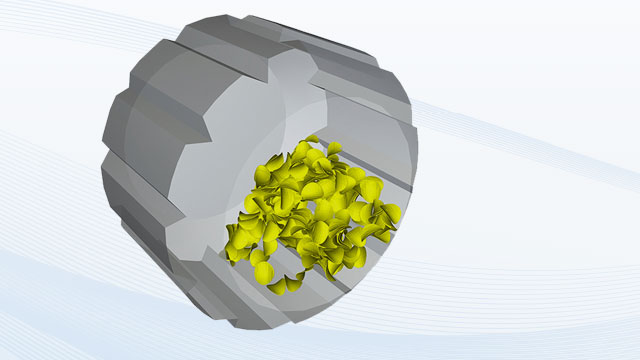

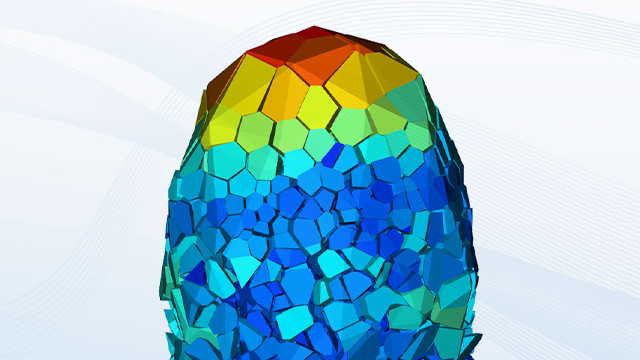

In addition to a library of standard shapes, almost any particle or solid shape can be scanned, while shell elements and even fibers with realistic material properties can be defined. Even highly complex movements with millions of particles can thus be quickly simulated and all kinds of crushing processes modeled.

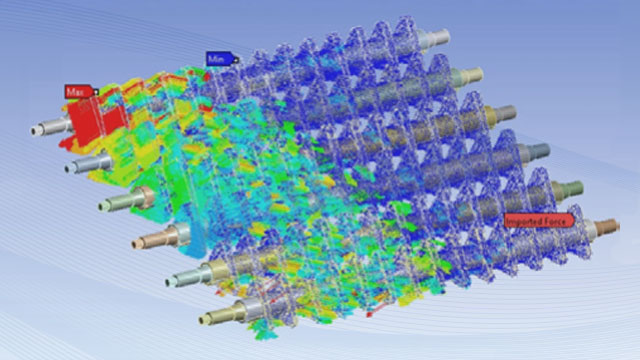

Furthermore, mechanical loading of solid elements and equipment wear and tear are predicted. Structure and fluid mechanics information can also be accessed by interfacing with Ansys Workbench, which incorporates FEA and CFD simulations. Never before has particle simulation been so simple, fast or precise as with ROCKY DEM.

CADFEM helps you to attain your goals

DEM is increasingly used in the process industry and process engineering. CADFEM offers its customers a compelling solution for simulating dynamic processes such as separating, sorting, aligning, filtering, screening, mixing, coating, drying, crushing, packaging or transportation.

ROCKY DEM is developed by simulation specialist ESSS at its sites in Brazil and the US. Due to its versatility and precision, it offers considerable added value for the entire process industry, from A for automation to Z for zones. The software offers a large range of capabilities and a seamless integration into the Ansys world. Project planning is crucial to the successful use of DEM. CADFEM offers you the advice, training and support needed for an efficient and fast use of DEM software, tailored to your requirements.

What can we do for you? We look forward to speaking with you.

Dr. sc. techn. Jorge Carregal-Ferreira

Success stories using DEM Simulation

Preetanshu Pandey, Ph.D. Principal Scientist at Bristol-Myers Squibb (BMS)“The best thing about Rocky DEM has to be its speed and realistic modeling of particle shapes. This allows us to precisely simulate with the exact number of particles in just the distribution, size and shape they will be when used later. This knowledge from the experimental studies is the biggest advantage of using Rocky DEM for us.”

Training relating to Ansys Rocky

Take part in CADFEM training on the topic of Ansys Rocky and learn how these solution concepts can be applied to your own tasks.

More Related Information

Get a deeper understanding of our solutions by taking advantage of our related offers.

The right solutions for your simulation projects

Simulation is everywhere and affects every industry. Since simulation requires more than software, CADFEM offers everything you need for successful simulation from a single source: software and IT solutions, consulting, support, engineering and knowledge sharing – always on the cutting edge.