Analysis of transient mixing processes using Discrete Element Modeling

Sector: Construction, Engineering firm/development service provider, Machinery and plant engineeringSpecialist field: Structural mechanicsROCKY DEM software is used to simulate mixing processes for the quantification of relevant variables. Such analyses are crucial in mechanical process engineering and particularly in the concrete industry, where Liebherr-Mischtechnik GmbH is one of the market leaders in mixing technology.

Summary

Task

Process requirements are defined in terms of mixing quality and throughput capacity. How do parameters, such as mixer geometry and speed, influence the mixing process?

Solution

With ROCKY, the mixing process can be simulated and evaluated transiently. Due to the quantitative evaluation of the mixing quality, the behavior of different mixers can be assessed. However, a profound understanding of the physical processes is necessary to make improvements.

Customer benefits

Using ROCKY, Liebherr has established an efficient optimization process for mixers. After their identification, relevant parameters are evaluated based on the mixing quality. The optimum operating parameters can then be derived from this evaluation.

Project Details

Task

In practice, process-related requirements are defined in terms of mixing quality and throughput capacity. The parameters affecting the mixing process are, for example, the type, geometry, and speed of the mixer. Here, the challenge is how to quantitatively record the influence of the parameters.

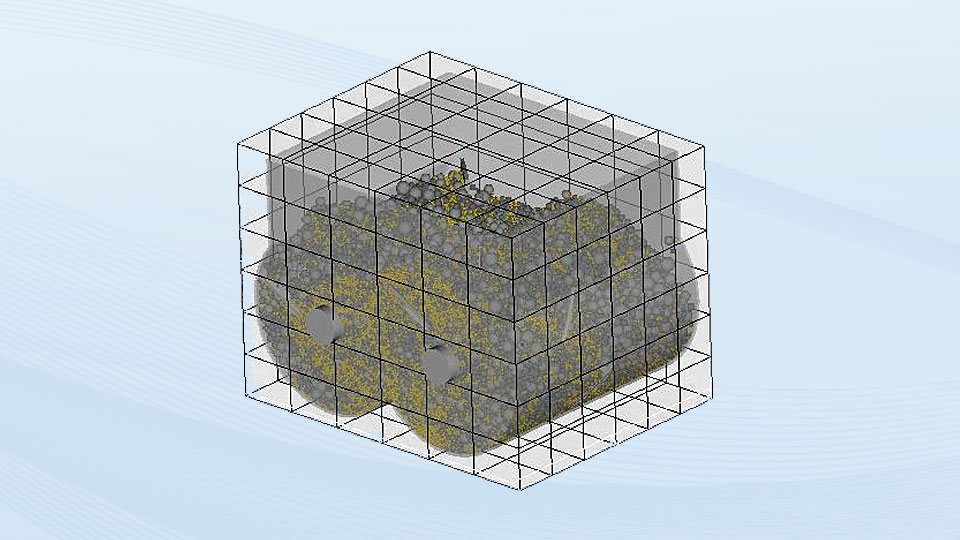

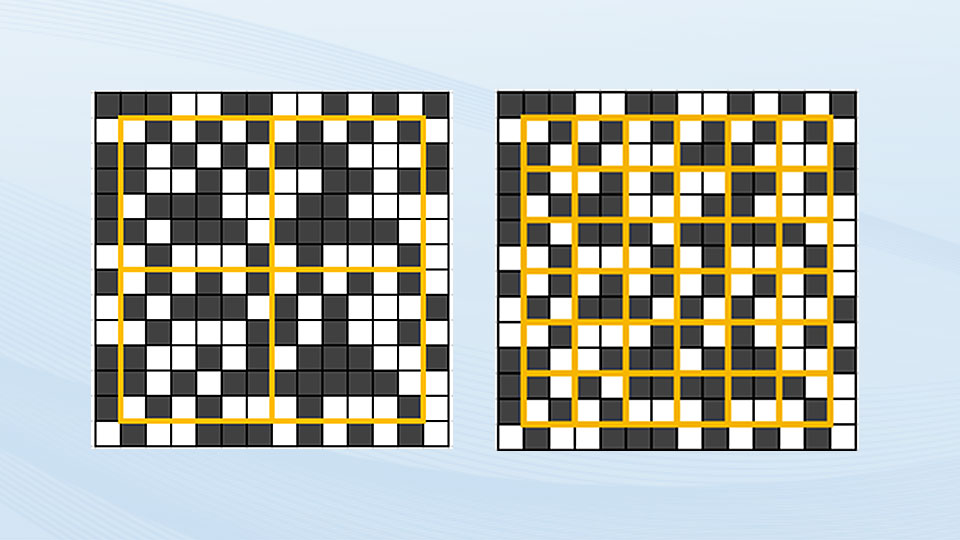

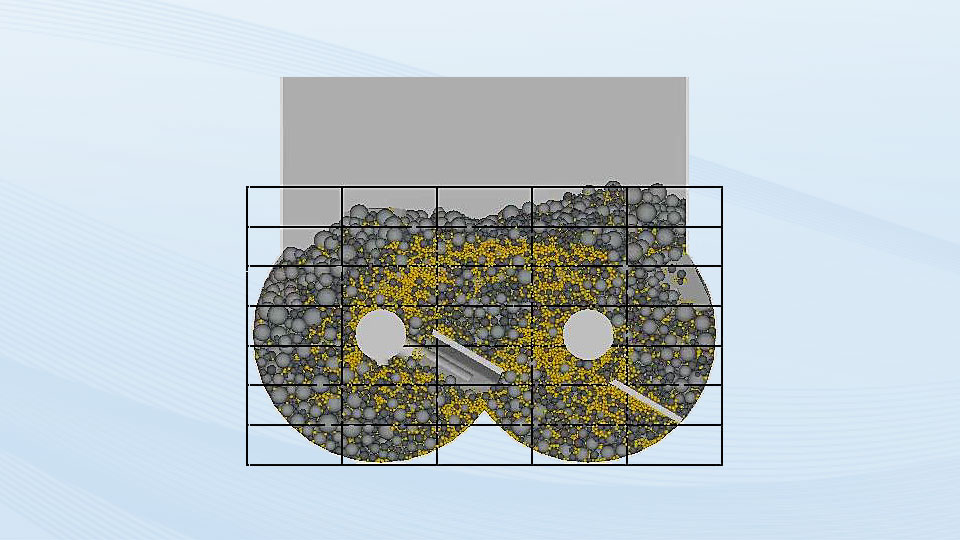

Liebherr-Mischtechnik GmbH developed a numerical evaluation method based on the DEM software ROCKY, which is used to simulate the mixing quality. The volume of the mixer is applied to a numerical evaluation grid in order to perform a statistical analysis. With an appropriate resolution of the evaluation grid, a statistically sufficient number of samples can be evaluated. Furthermore, insights can be obtained about the spatial distribution of the mixing quality in the mixer, and the temporal course of the mixing quality during the mixing process.

Solution

The described method can be used regardless of the mixer type and geometry. With ROCKY, the mixing process is simulated and evaluated transiently, although premature statements based on visualizations from the post-processing should be avoided. The quantitative evaluation of the mixing quality mentioned above enables the behavioral evaluation of various mixers. However, a profound understanding of the physical processes is necessary to explain the results and to derive meaningful measures.

Customer Benefit

With the ROCKY software, Liebherr-Mischtechnik GmbH has a powerful simulation tool and could establish an efficient optimization process for mixers. This allows both the generation of new mixing processes and the optimization of existing ones. After the identification of the relevant parameters, they can be evaluated based on the simulated mixing quality. Finally, strategies for the selection of the optimum operating parameters can be derived.

Images: © LIEBHERR